Automatic weighing device for sheep

An automatic weighing device and weighing technology are applied in the direction of measuring devices, weighing, and weighing equipment for materials with special properties/forms. Achieve the effect of accurate weighing, reduce labor intensity and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

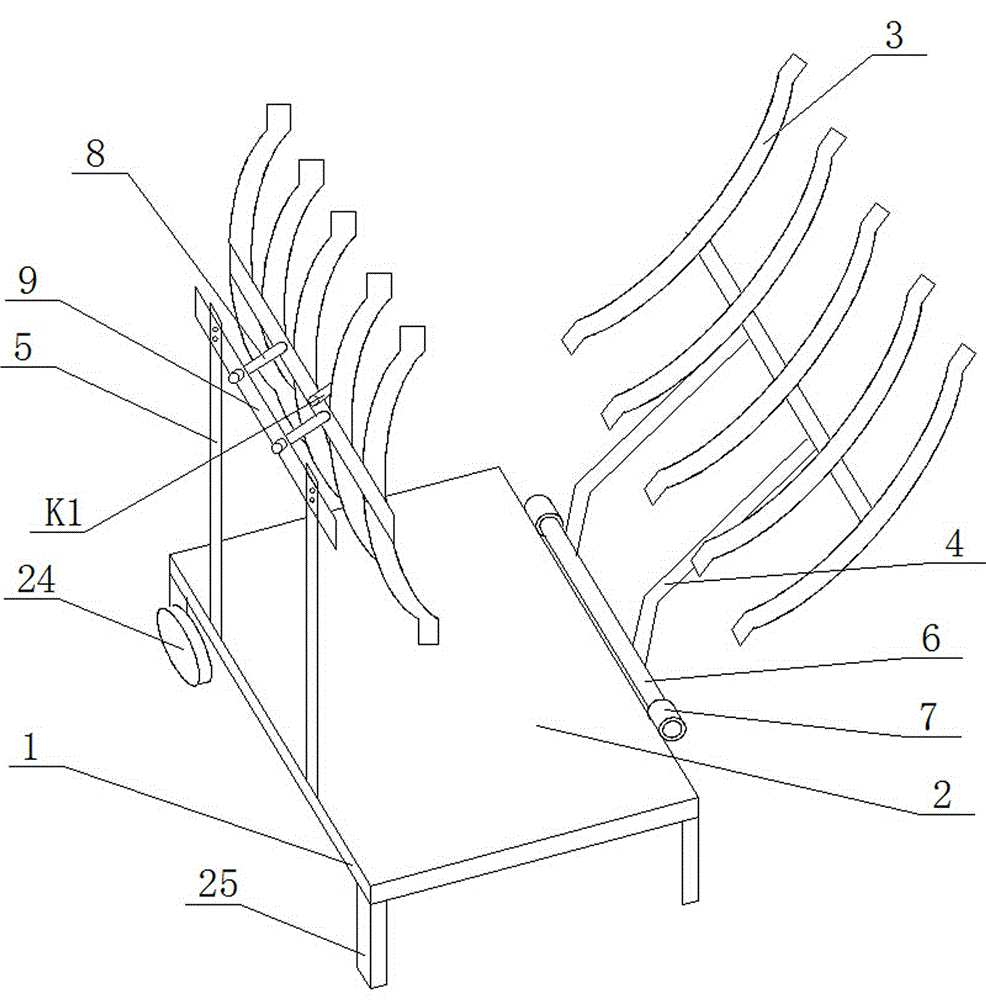

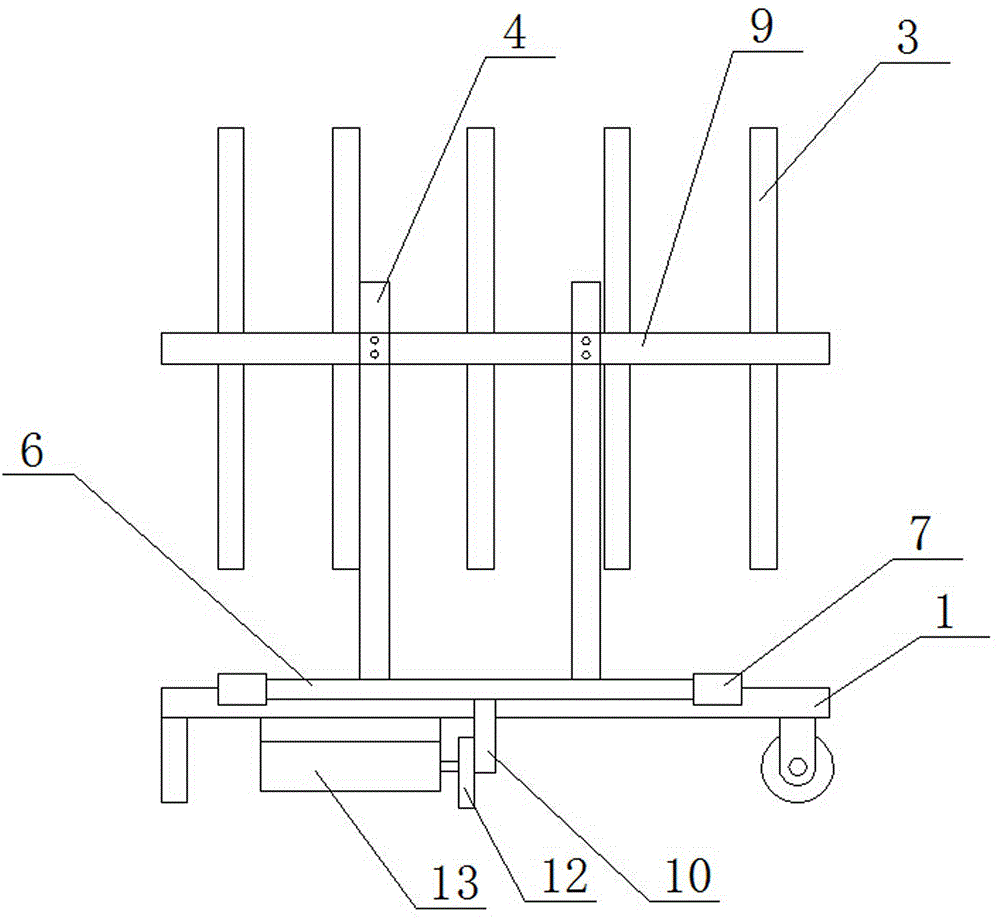

[0029]As shown in the figure, the present invention includes a base 1 and a control circuit. A weighing platform 2 is installed on the base 1. The weighing platform transmits the weighing data to the data display recorder through the sensor or directly inputs the data to the computer; Guardrails 3 are installed on both sides through brackets 5. The guardrails 3 are arranged oppositely and adapted to the body shape of the sheep. They are used to hold the sheep in place to prevent the sheep from jumping when weighing and damage the weighing device. At the same time, causing weighing The weight is not accurate. The support on one side is a movable support 4 and is movably installed on the base 1. The bottom end of the movable support is fixed on the cross bar 6, and the two ends of the cross bar 6 are installed in the axle sleeve 7 with gap fit. Fixed on the base 1, so that the movable bracket rotates with the cross bar 6 on one side of the base as the centerline; the bottom end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com