Contour control device and method for direct-drive gantry type motion platform

A technology of motion platform and contour control, applied in the direction of digital control, electrical program control, etc., can solve the problem of reducing the processing accuracy of the system contour

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

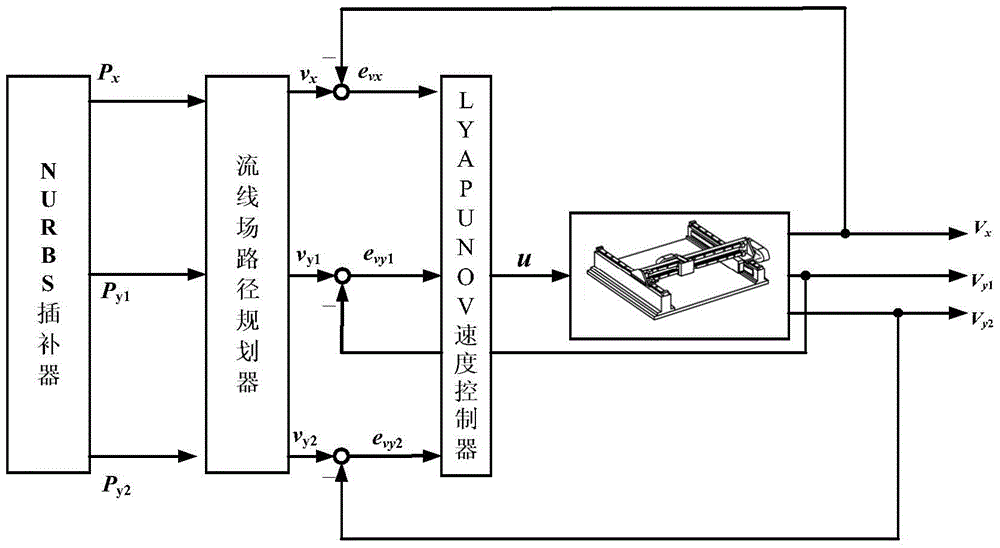

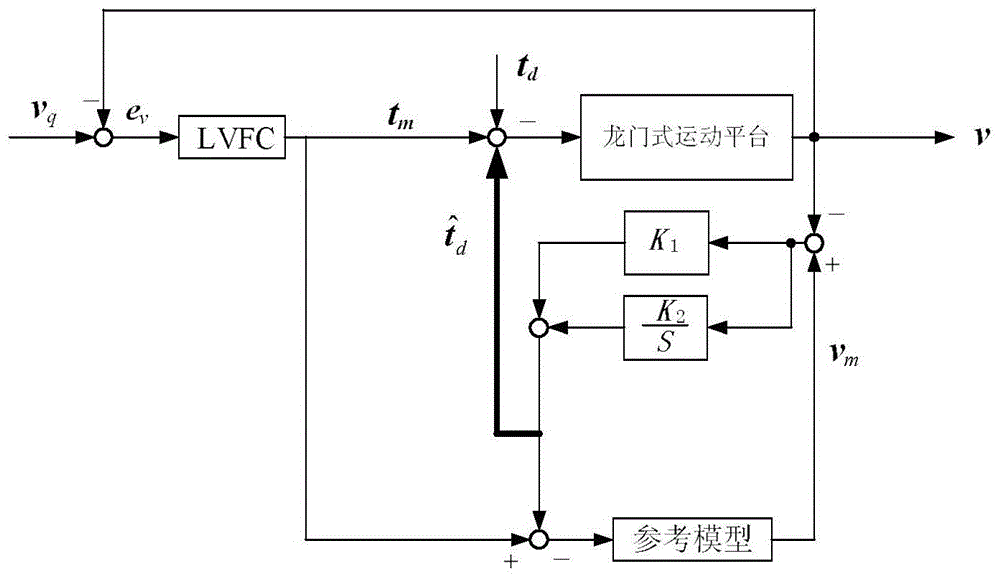

[0093] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

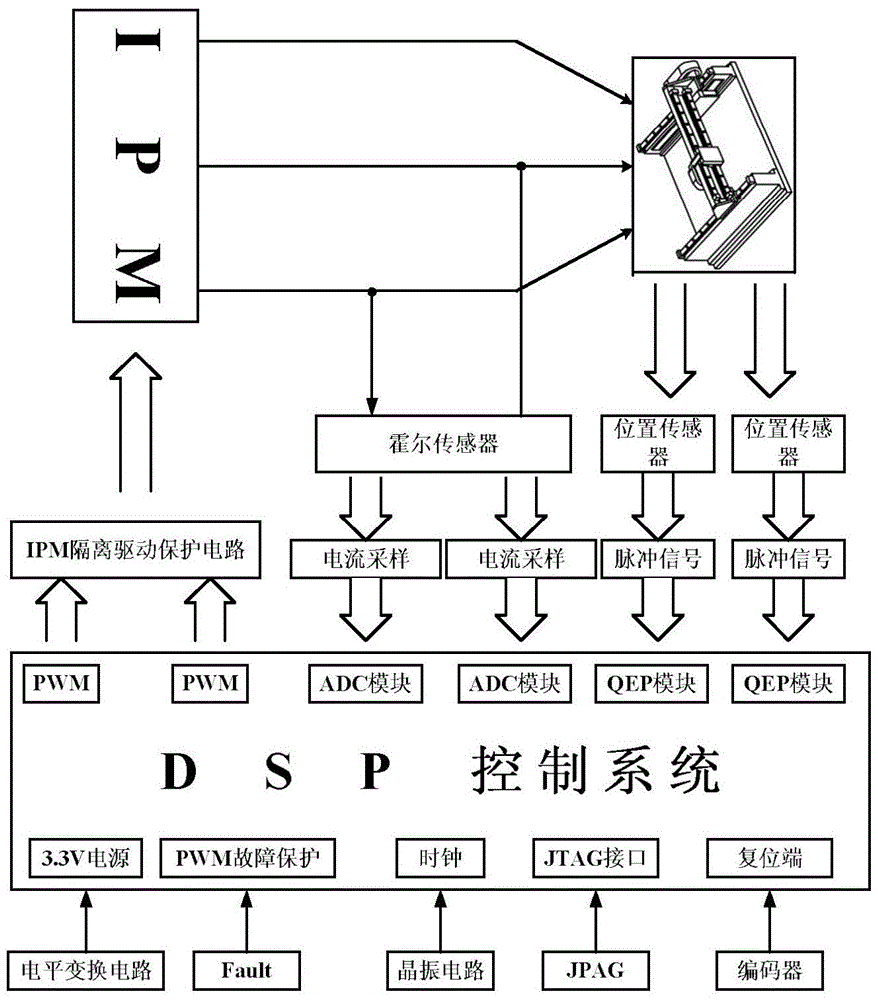

[0094] Such as figure 1 As shown, a direct drive gantry type motion platform contour control device, including IPM (IntelligentPower Module), Hall current sensor, position sensor, DSP control system, IPM isolation drive protection circuit;

[0095] The output end of the IPM is connected to the input end of the three-phase winding of the stator of the direct drive gantry type motion platform 2Y\X direction linear motor;

[0096] There are two Hall current sensors and two position sensors. The input ends of the two Hall current sensors are respectively connected to the 2Y\X direction linear motors of the direct drive gantry type motion platform, and the input ends of the two position sensors are respectively connected to the direct drive gantry type motion platform. The 2Y\X direction linear motor of the motion platform, the outp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com