Multifunctional threshing drum and corresponding combine harvester

A threshing drum and multi-functional technology, applied in harvesters, threshing equipment, applications, etc., can solve the problems of broad-spectrum harvesting of different crops, reduce labor intensity and harvest costs, reduce labor intensity and use costs, and improve The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

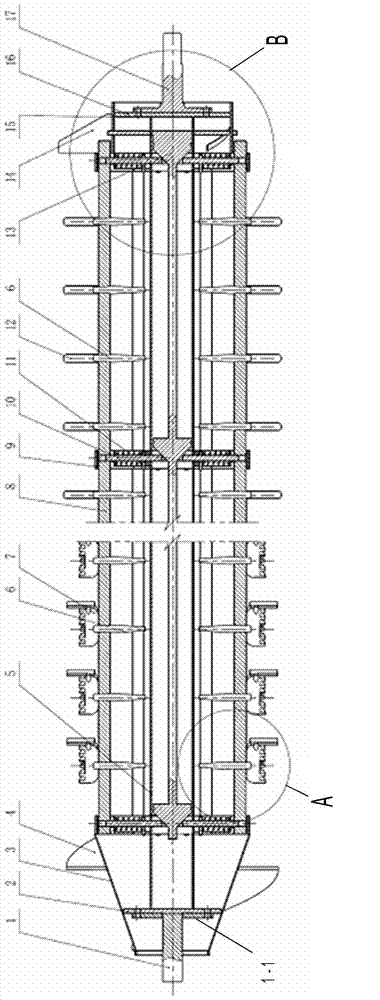

[0039] Exemplary embodiments of the present invention will be described in detail below with reference to the accompanying drawings. The description of the exemplary embodiments is for exemplary purposes only and is in no way limiting of the invention and its application or usage.

[0040]In view of the problems existing in the prior art, the present invention proposes a threshing drum capable of threshing different crops. The threshing drum according to the present invention can realize the replacement of threshing elements through a simple locking structure, thereby realizing threshing and threshing of different crops. reward. Similarly, a combine harvester employing the threshing drum according to the present invention enables harvesting of a variety of grains without replacing the threshing drum.

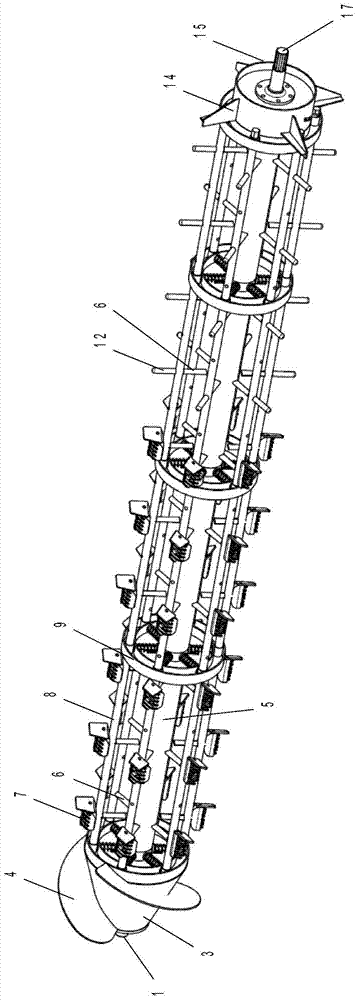

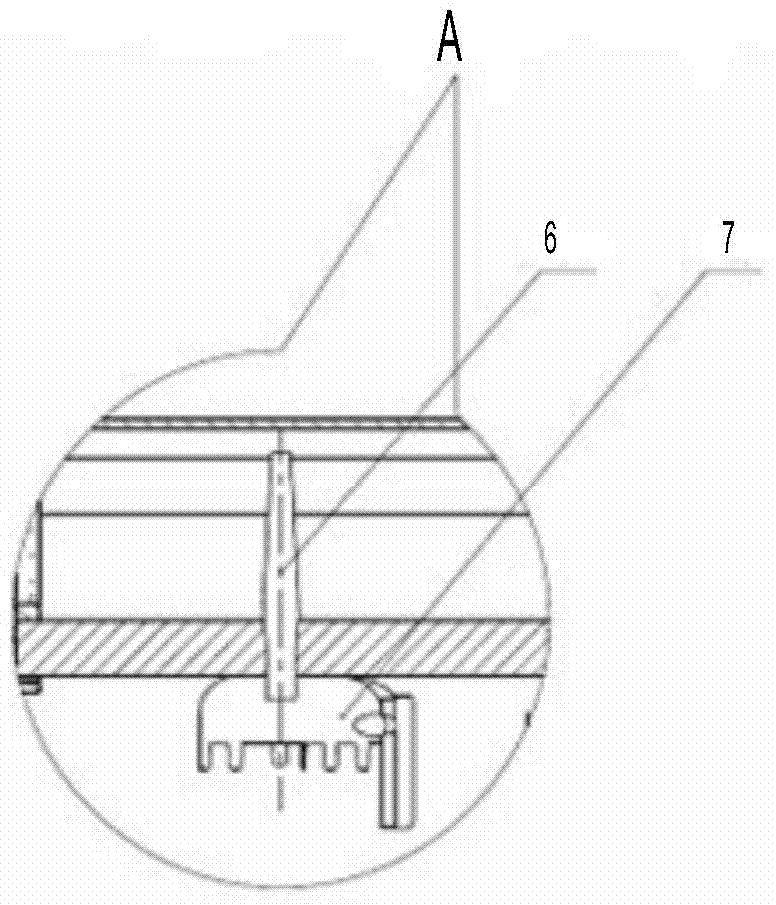

[0041] The present invention provides a multifunctional threshing drum 100 comprising a drive shaft for powering the drum, a threshing element support rod arranged to rotate wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com