A single-machine single-station stretching manipulator

A single-station, manipulator technology, applied in the direction of manipulators, program-controlled manipulators, positioning devices, etc., can solve the problems of short service life of molds, easy positioning, low work efficiency, etc., to improve service life, avoid waste, improve The effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

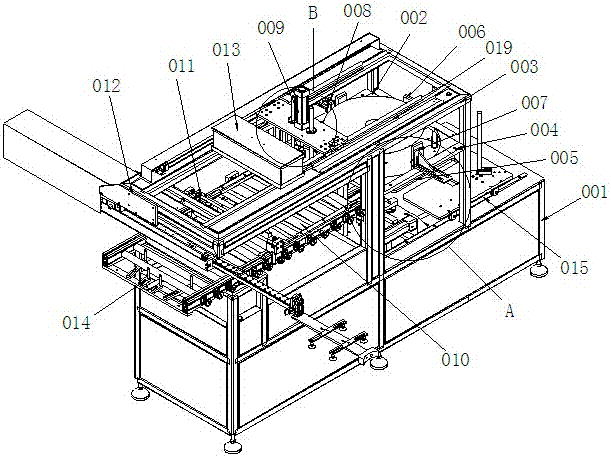

[0022] Such as Figure 1 to Figure 3 A single-machine single-station stretching manipulator of the present invention is schematically shown.

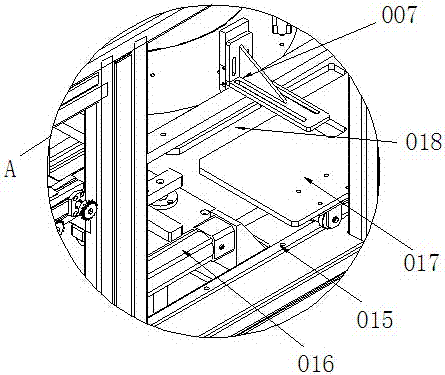

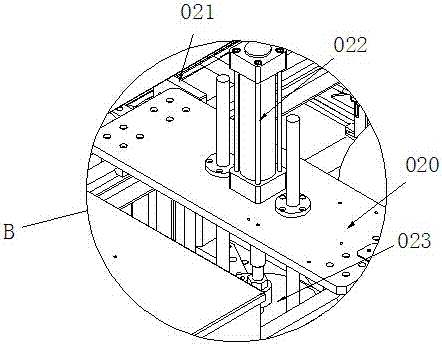

[0023] A single-machine single-station stretching manipulator provided in this embodiment, please refer to figure 1 , comprising a frame 001, on which a working platform 002 is arranged, on which a beam 003 is arranged, the working platform 002 is a stepped platform, and the middle part of the beam 003 is provided with The flat second column 004 of the working platform 002, the second column 004 and the upper edge of the working platform 002 form a loading area, and an automatic feeding device 005 is provided below the loading area. The feeding position of device 005 is provided with auxiliary device, and auxiliary device is arranged on the second cylinder 004, and described auxiliary device includes positioning asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com