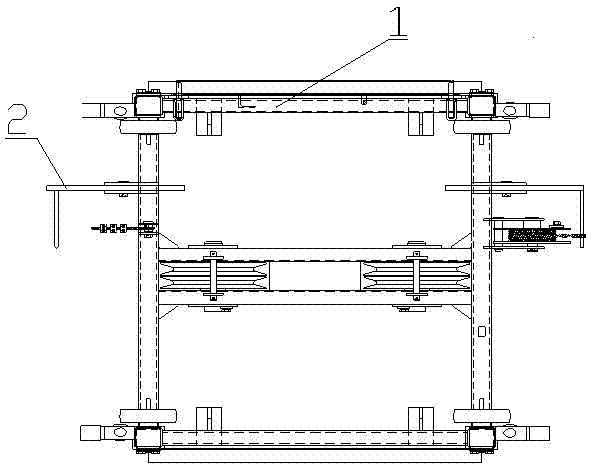

Anti- rope-breaking protection device for heavy-load trolley

A protection device and anti-broken rope technology, which is applied in the direction of cranes, etc., can solve the problems of reducing the service life of steel wire ropes, without any smoothing or lubrication measures, and damage to steel wire ropes, so as to ensure normal service life, humanized structural design, and reduce direct damage. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing.

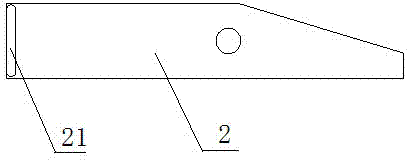

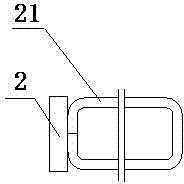

[0017] like Figure 4 to Figure 6 As shown, the present invention is provided with anti-off rope device, and a nylon pulley block 3 is set at the heavy end of the brake lever 2, and the traction wire rope passes through the pulley slot of the pulley block 3. Under normal working conditions, the wire rope can always drive the pulley Rotate to play an effective anti-wear effect; and the lower part of the pulley traverses an anti-off shaft 4, which is used to prevent the traction wire rope from breaking away from the draw-in groove of the pulley. Utilizing the pulley block 3 device greatly reduces the degree of direct wear between the anti-broken rope device and the steel wire rope, effectively avoiding the wear and tear of the steel wire rope.

[0018] By applying this technology, the load trolley 1 of XGT100A(6012) greatly reduces the degree of direct wear between the anti-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com