Anti-cheating device capable of working during power outage for refueling machine

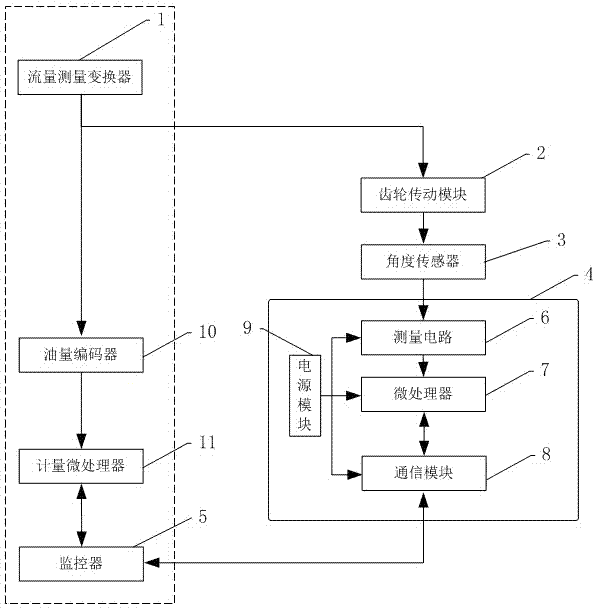

A fuel dispenser and anti-cheating technology, applied in distribution devices, special dispensing devices, liquid distribution, transportation or transfer devices, etc., can solve problems such as changing the metering motherboard chip of the fuel dispenser or cheating in software, so as to safeguard legitimate rights and interests and protect the market. Order, the effect of improving the ability to prevent cheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

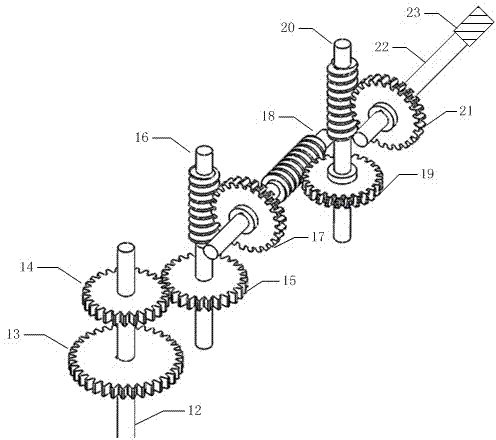

Method used

Image

Examples

example 1

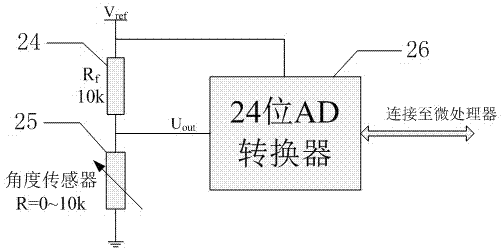

[0055] Calculation example 1: θ saved by monitor 5 before power failure off 25.53 degrees, the angular position θ read by the monitor 5 after power-on again on Is 30.31 degrees, then Δθ=4.78°=0.083(rad)>θ calculated by formula (4) th . From equation (8), ΔV=17.04L can be calculated. This shows that there is a change in the oil output of the refueling machine when the power is off, and there is a suspicion of cheating. The monitor can issue a cheating alarm signal and lock the tanker, waiting for the metering department to re-verify the tanker.

example 2

[0056] Calculation example 2: θ saved by monitor 5 before power failure off 25.53 degrees, the angular position θ read by the monitor 5 after power-on again on Is 25.42 degrees, then Δθ=-0.11° th . The monitor 5 will determine that there is no change in the oil output of the refueling machine when the power is off. The small changes in the measured angular position may be caused by the temperature drift of the resistance value of the angle sensor during the power failure, the small mechanical vibration of the tanker during the power failure, the small resistance fluctuations, or the random error of the two measurements before and after the power failure.

example 3

[0057] Calculation example 3: θ saved by monitor 5 before power failure off 25.53 degrees, the angular position θ read by the monitor 5 after power-on again on Is 26.74 degrees, then Δθ=1.21°=0.021(rad)>θ th . From equation (8), ΔV=4.31L can be calculated. This shows that there is a change in the oil output of the refueling engine when the power is off, but there is no obvious suspicion of cheating. The monitor can send out abnormal alarm signals and count abnormalities. If similar situations occur multiple times in a row, the monitor will determine that an abnormal cumulative alarm signal is issued and the tanker will be locked, waiting for the metering department to re-verify the tanker or the supplier to repair the tanker.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com