A method for checking the looseness of iron tower bolts

A technology for loosening bolts and iron towers, which is applied to towers, optical device exploration, building types, etc., can solve problems such as waste of human resources, falling off, falling towers, etc., and achieve the effect of avoiding potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

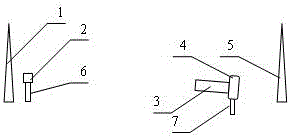

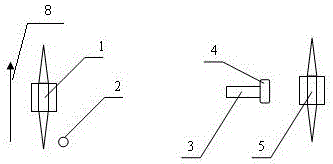

[0022] 1. Prepare the following equipment first: Use the video recording function of 5DIII camera 4, replace with at least 32G memory card, or external storage; use 600mm long-distance fixed-focus lens; iron monopod camera frame 7 (stable and reliable, will not Blown by the wind); adopt the Siemens model QVM62.1 wind speed sensor and wind speed, wind direction recorder 2; steel bracket 6 (can be inserted into the soil).

[0023] 2. The camera is calibrated with the lens for visual measurement and calculation, and the camera 4 is adjusted to the clock of the wind speed and wind direction recorder 2 to be consistent.

[0024] 3. Install the wind speed sensor, wind direction, and wind speed recorder 2 on the steel bracket 6 on site, insert the steel bracket 6 into the soil on the edge of the windward side of the tower, the wind speed sensor i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com