A bracket system for horizontal steel pipes

A support system and steel pipe technology, applied in the field of support systems, can solve problems such as instability of the support system and pipe shaking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

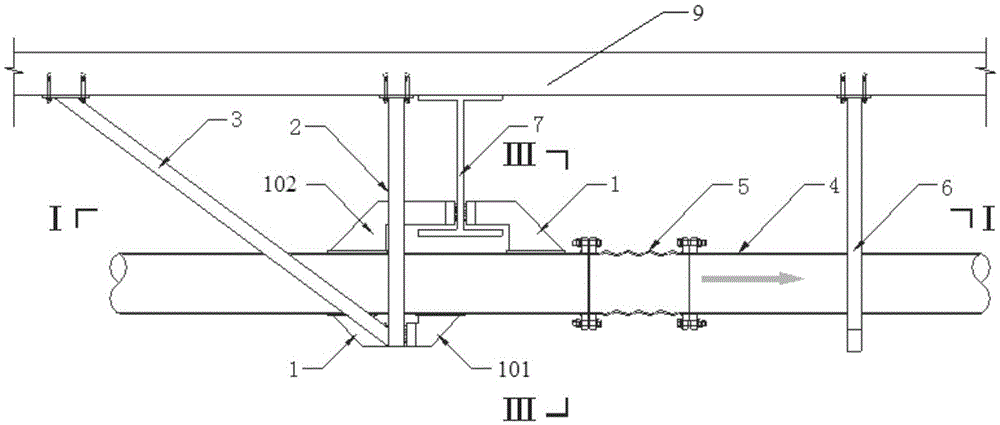

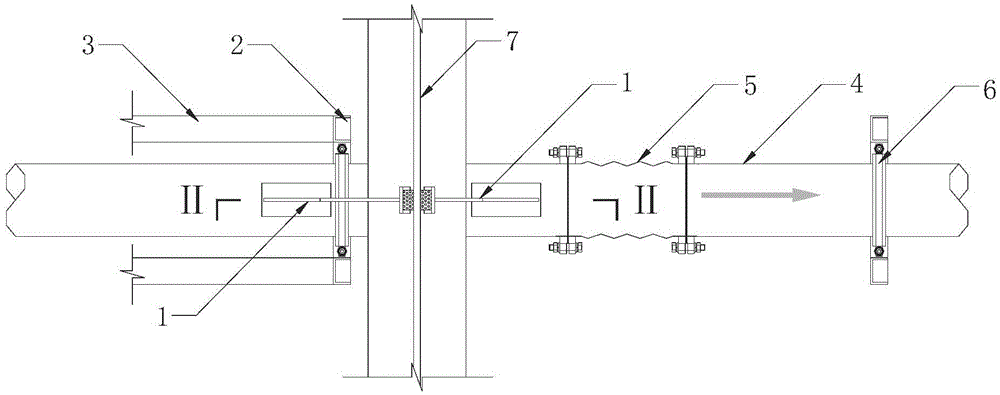

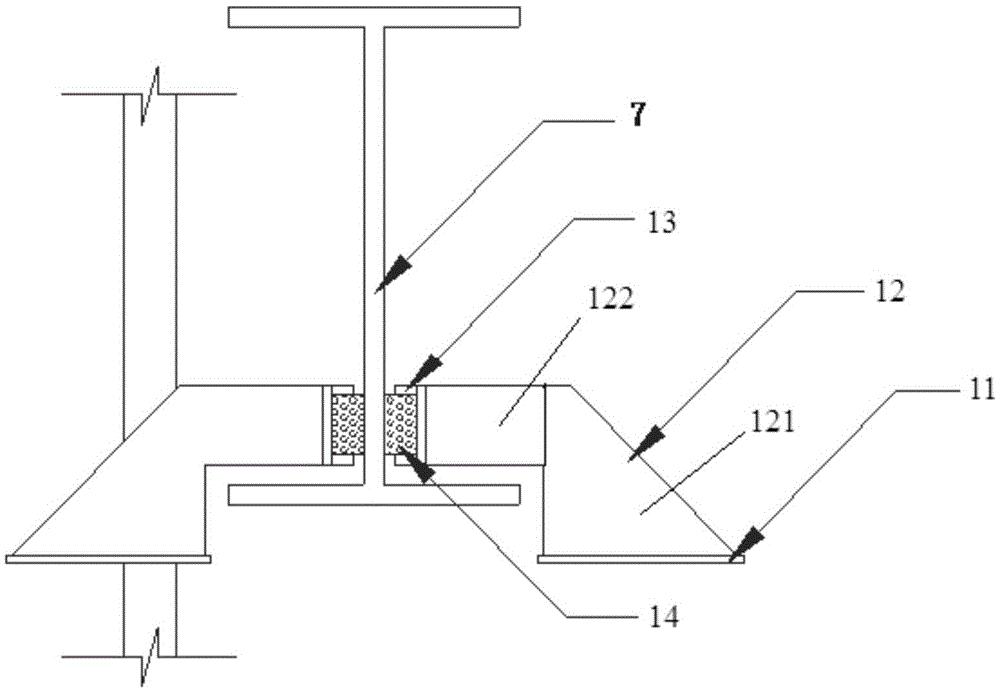

[0019] Figure 1~4 A schematic diagram of the installed support system for horizontal steel pipes in the present invention is shown in . The bracket system of the present invention includes a fixed bracket assembly and a guide bracket assembly 6 . The fixed support assembly includes a U-shaped fixed support 2 for carrying the steel pipe 4 and the weight of the internal fluid, a fixed support diagonal brace 3 and a directional support 1; the directional support 1 includes a first directional support assembly 101 and The second directional support assembly 102, the first directional support assembly 101 includes two directional support units located on both sides of the beam of the U-shaped fixed bracket 2 along the pipeline axis direction, the second directional support The bracing assembly 102 includes two directional bracing units located on both sides of the structural section steel 7 along the axial direction of the pipe; each directional bracing unit includes a crossbeam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com