Device and method for monitoring vertical deformation of hydraulic construction

A technology for hydraulic structures and monitoring devices, applied in measurement devices, optical devices, height/level measurement, etc., can solve problems such as difficulty in circuit setting, construction and layout, monitoring of uneven settlement, etc., to reduce engineering monitoring and The effect of testing cost, convenient project transportation and use, convenient installation, inspection and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

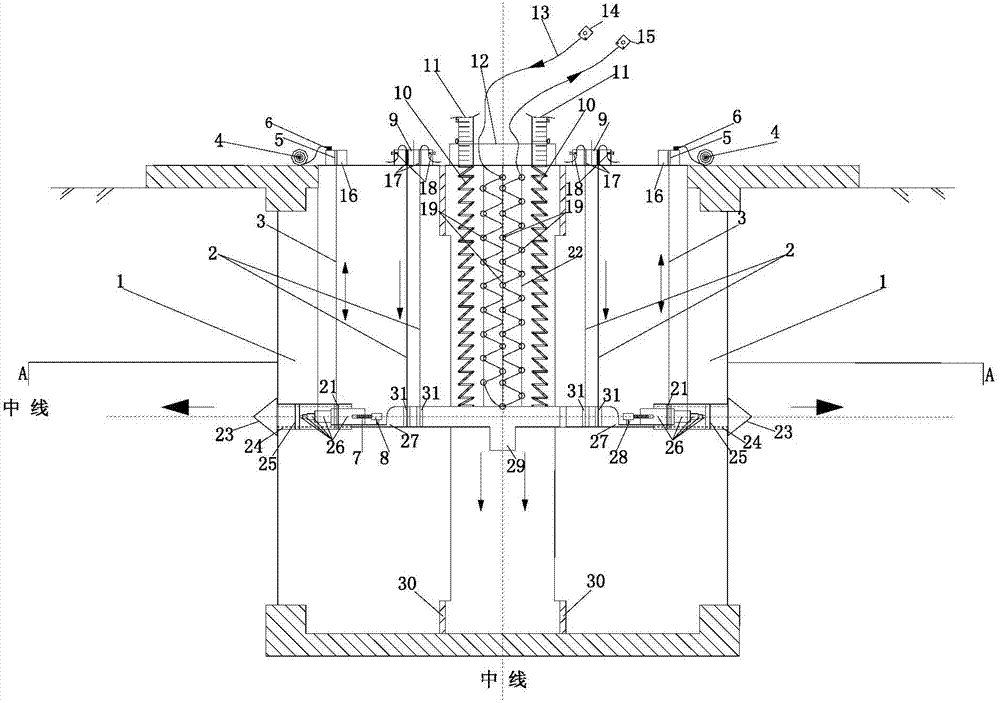

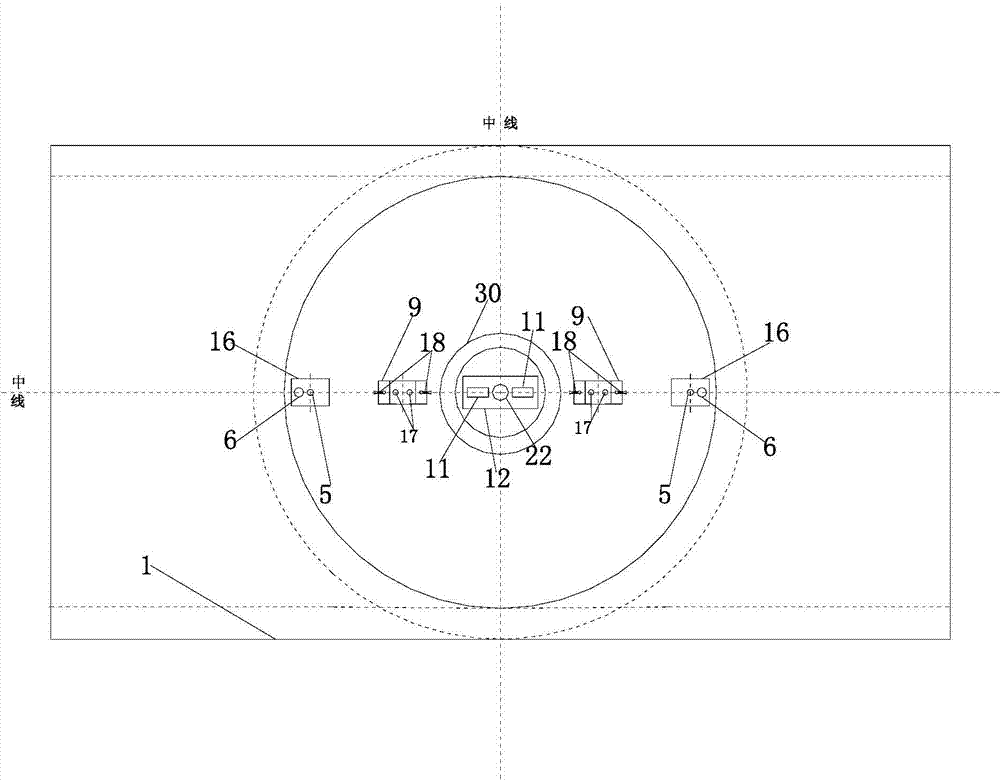

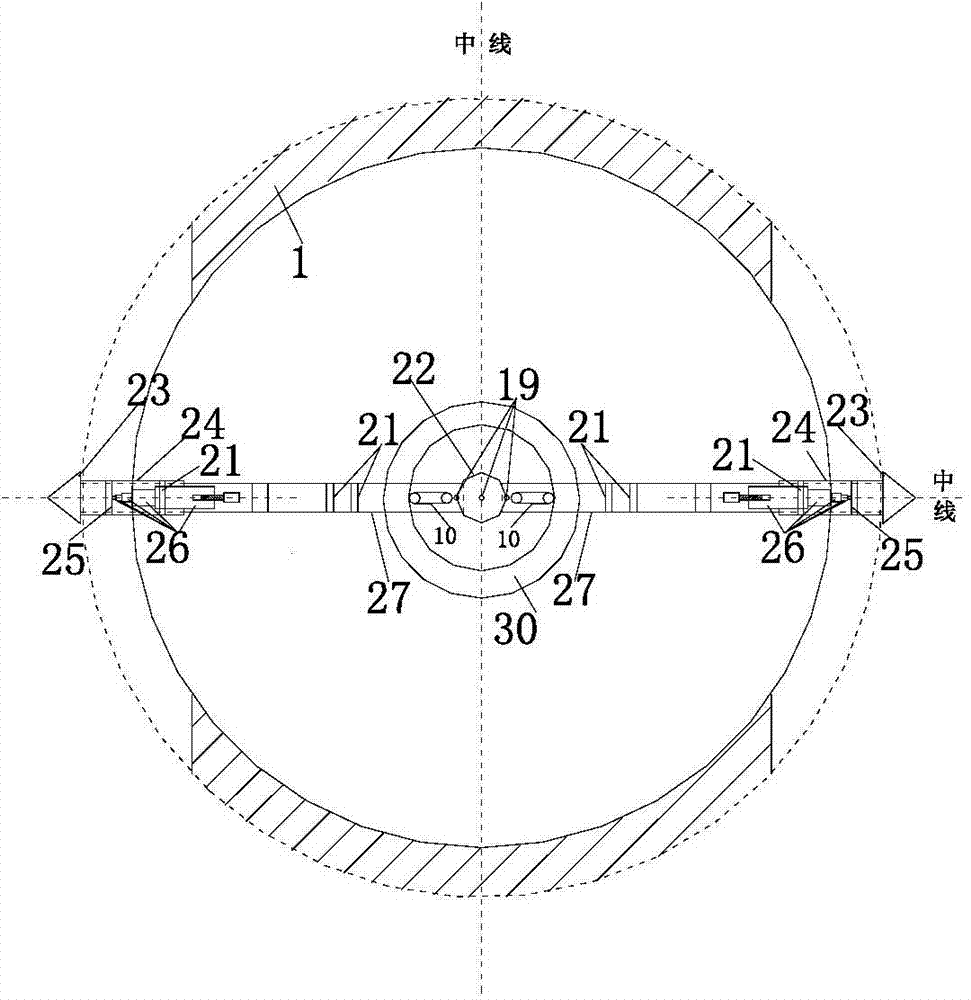

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

[0026] like Figure 1 to Figure 6As shown, a vertical deformation monitoring device for a hydraulic structure of the present invention includes a bottom-through shaft 1 located in the earth-rock joint area, an inner tube 30 located inside the bottom-through shaft 1, and the bottom-through shaft 1 is provided with lugs, Hanging on the earth-rock joint area through the lugs, a displacement platform 27 is installed in the inner tube 30 of the carrier, and the two sides of the displacement platform 27 are symmetrically installed with a drive motor 8, and the drive motor 8 is installed on the displacement platform through a bracket. 27, the drive motor 8 is connected with the drive shaft 7, the drive shaft 7 is provided with external threads, the drive shaft 7 is inserted into the five-stage piston 26, the five-stage piston 26 is provided with internal threads that cooperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com