Wall adhering receptacle and manufacturing method thereof

A manufacturing method and plug-in board technology, applied to electrical components, bases/shells, coupling devices, etc., can solve problems such as potential safety hazards, achieve the effects of reducing weight, reducing potential safety hazards of electric shock, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, but not as a limitation to the present invention.

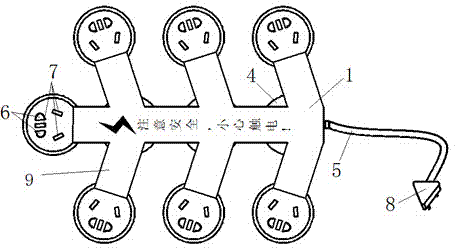

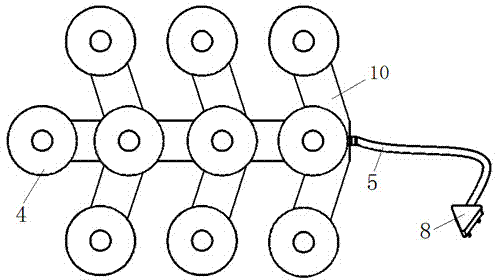

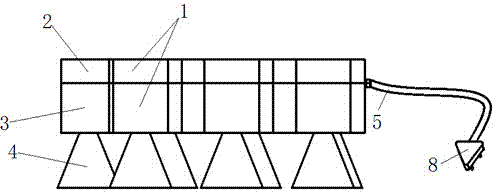

[0012] Embodiment of the present invention: a method for making a wall-mounted plugboard. Firstly, a plugboard body composed of a dendritic upper cover and a lower cover is made, and two sockets are made on each branch-like rod of the upper cover. And the three-head jack, each branch of the lower cover is made with a suction cup that can be adsorbed on the wall. This setting makes it easier for the plug-in board to be attached to the smooth wall through the suction cup, reducing the potential safety hazard of electric shock.

[0013] A wall plug-in board, including electric wires 5 and plugs 8 connected to the plug-in board body 1, the plug-in board body 1 is formed by connecting a dendritic upper cover 2 and a lower cover 3, and each upper branch of the upper cover 2 Two jacks 6 and three jack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com