Inside-pipe filling technology

A technology, the technology of inner diameter, applied in the field of tube filling technology, can solve the problems of physical health impact, waste of wood resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

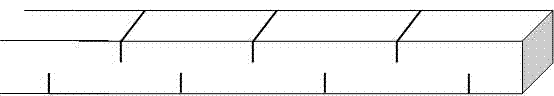

[0007] As shown in the figure, a tube filling technique is used to process wood into a square of the same size as the inner diameter of the hollow tube to be filled, and then use a saw to cut the square into sections. The depth of the sawing road is half the size of the square. Saw the opposite side of the wooden square into sections of the same depth and length so that the wooden square never deforms in the tube.

[0008] This solution solves the worries about the harm of formaldehyde to the human body, saves a lot of wood resources, and facilitates installation and construction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com