Casting device, solution film forming equipment and method

A casting film and casting technology, applied in the direction of flat products, coatings, household appliances, etc., can solve the problems of difficult to peel the cast film, and achieve the effect of suppressing interface confusion and blurring unevenness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

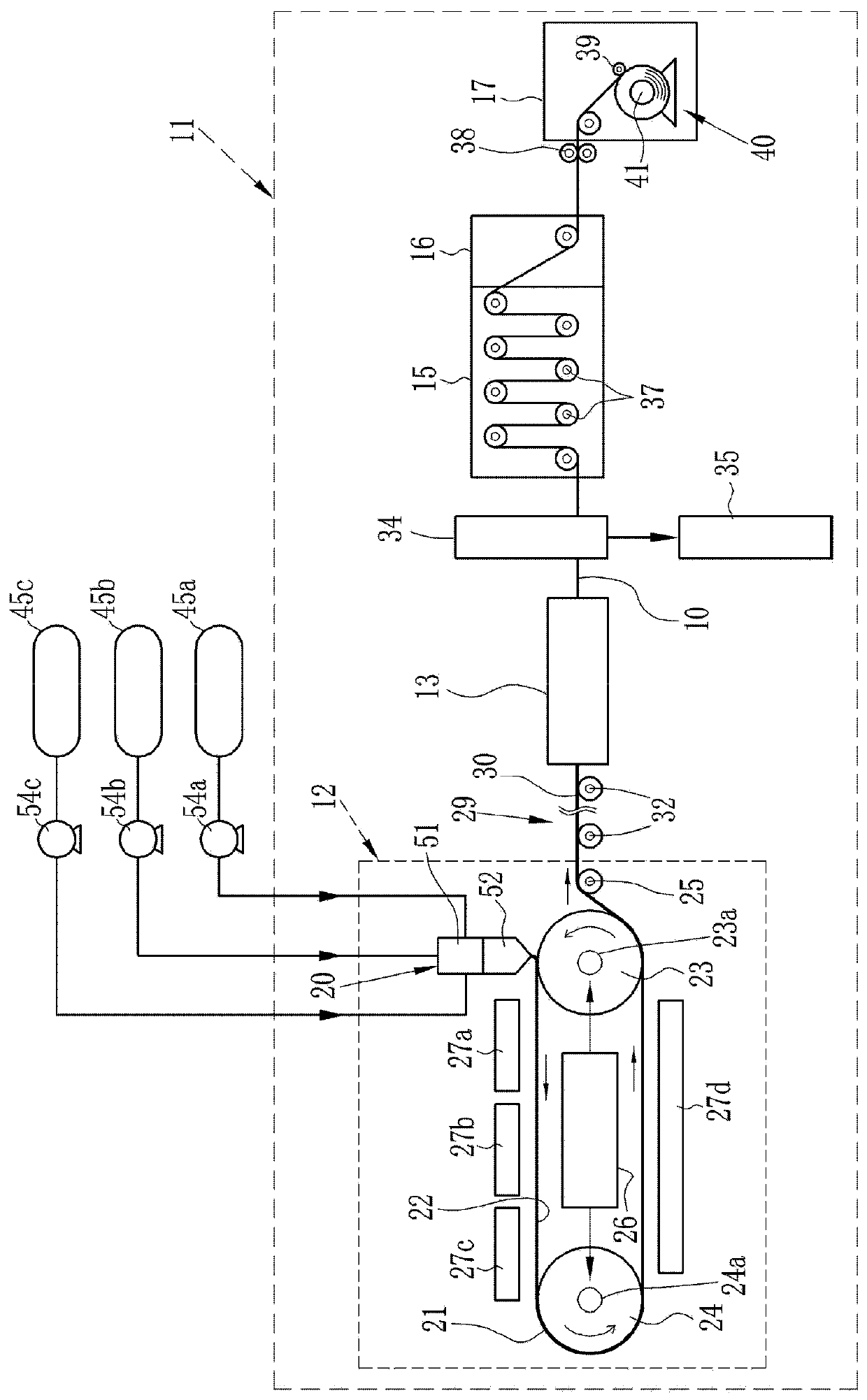

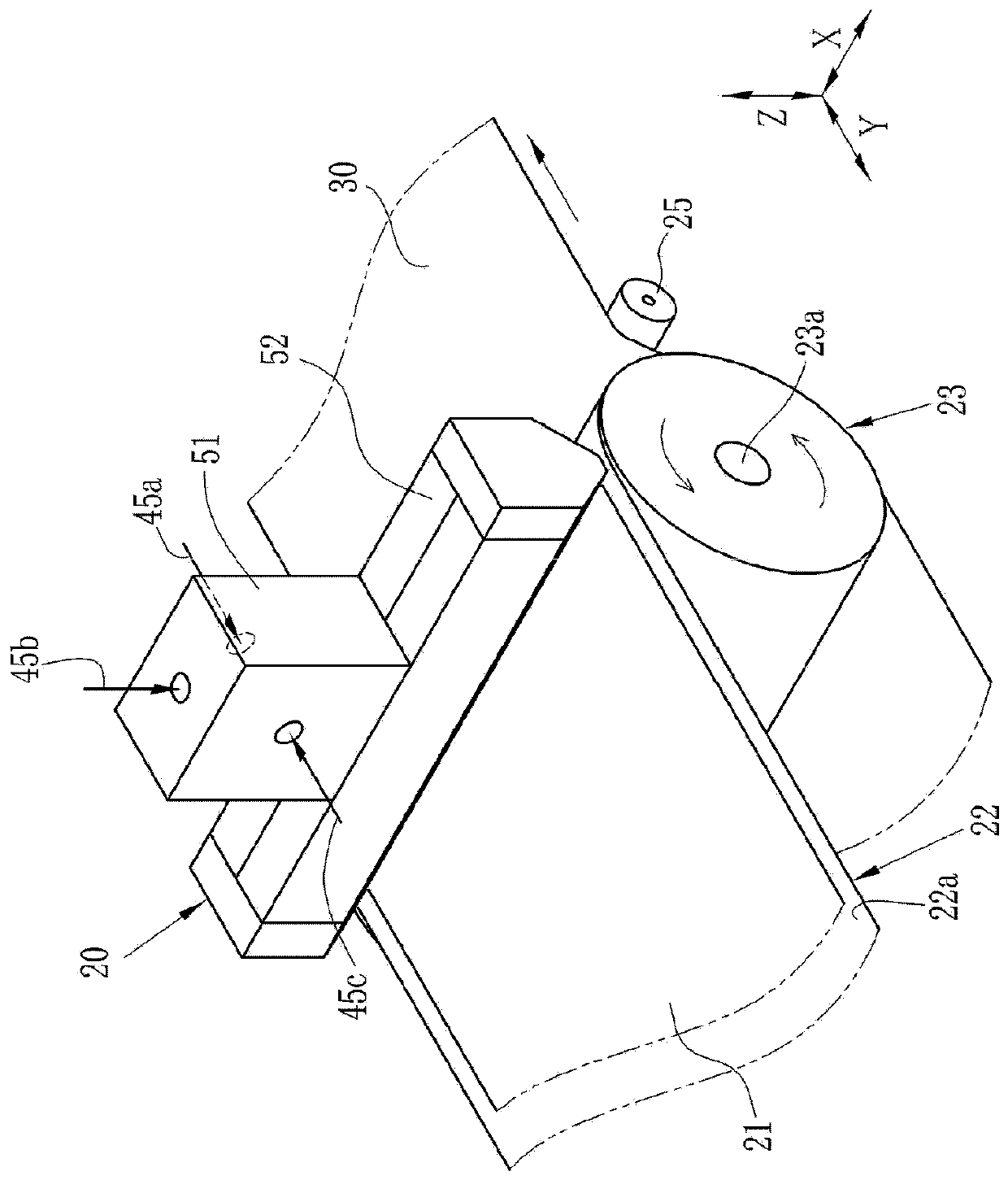

[0186] Example 1 to Example 4 were carried out as examples of the present invention. Each of the examples was implemented by using the solution film forming equipment 11, and the examples were performed by changing the shear viscosity ratios ηm / ηsa, ηm / ηsc and the above-mentioned radius of curvature R in the junction 62. Table 1 shows the ratio of each shear viscosity and the radius of curvature R. In addition, in any of the examples, the shear viscosity ηsa of the first dope 45a in the junction 62 is equal to the shear viscosity ηsc of the third dope 45c, so the ratio of the shear viscosity in Table 1 is simply expressed as "ηm / ηs".

[0187] The ratio of the shear viscosity is adjusted by adjusting the interval in the Y direction of the first dope slot portion 59a connected to the confluence portion 62, the third dope slot portion 59c, and the second dope slot portion 59b.

[0188] [Table 1]

[0189]

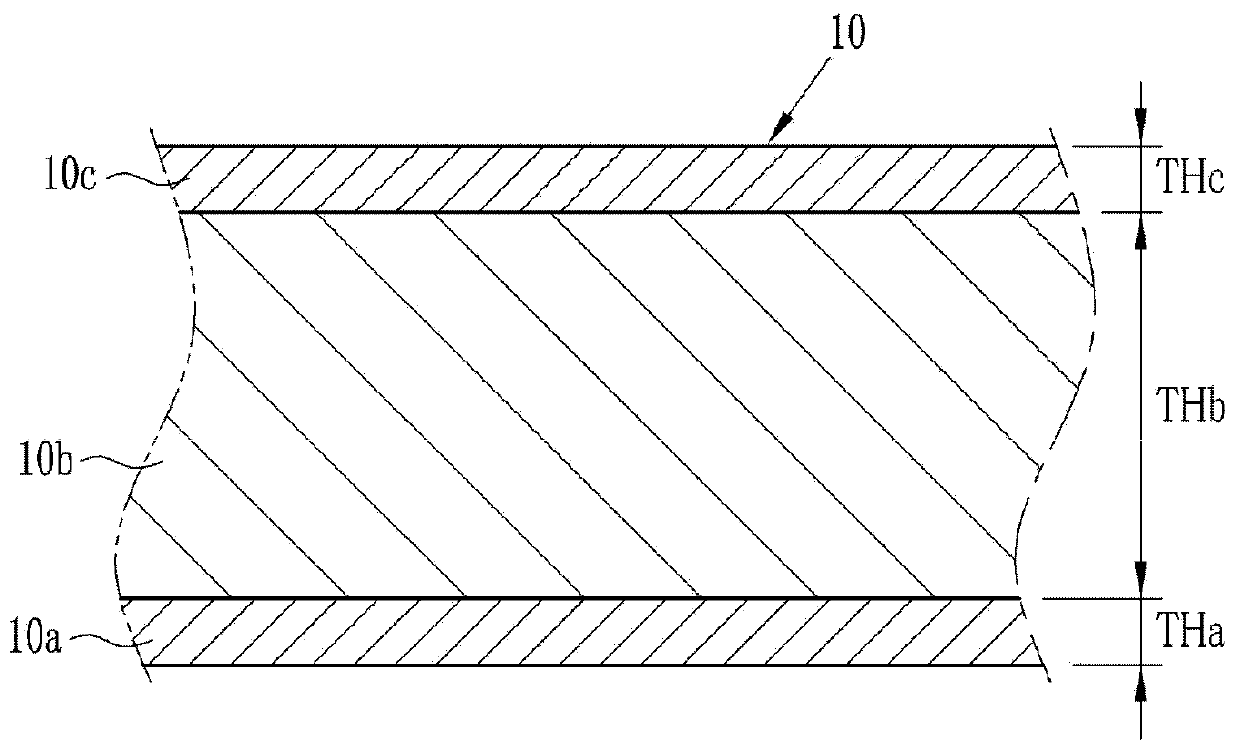

[0190] The width of the manufactured multilayer film 10 was 1500 mm....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com