High temperature apparatus and method for silicon carbide growth

A high-temperature device and growth method technology, applied in the field of semiconductors, can solve the problems of raising the cost of silicon carbide semiconductors, power consumption, etc., and achieve the effects of reliable structure, high safety, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The exemplary embodiments of the present invention will be described below with reference to the accompanying drawings. For the sake of clarity and conciseness, the actual embodiments are not limited to the technical features described in the specification. However, it should be understood that in the process of improving any one of the actual embodiments, the decisions of multiple specific embodiments must be able to achieve the specific goals of the improver, for example, to comply with industry-related and business-related restrictions. The limitations vary from embodiment to embodiment. Moreover, it should be understood that even though the aforementioned improved effect is very complicated and time-consuming, it is still a conventional technical means for those skilled in the art who know the benefits of the present invention.

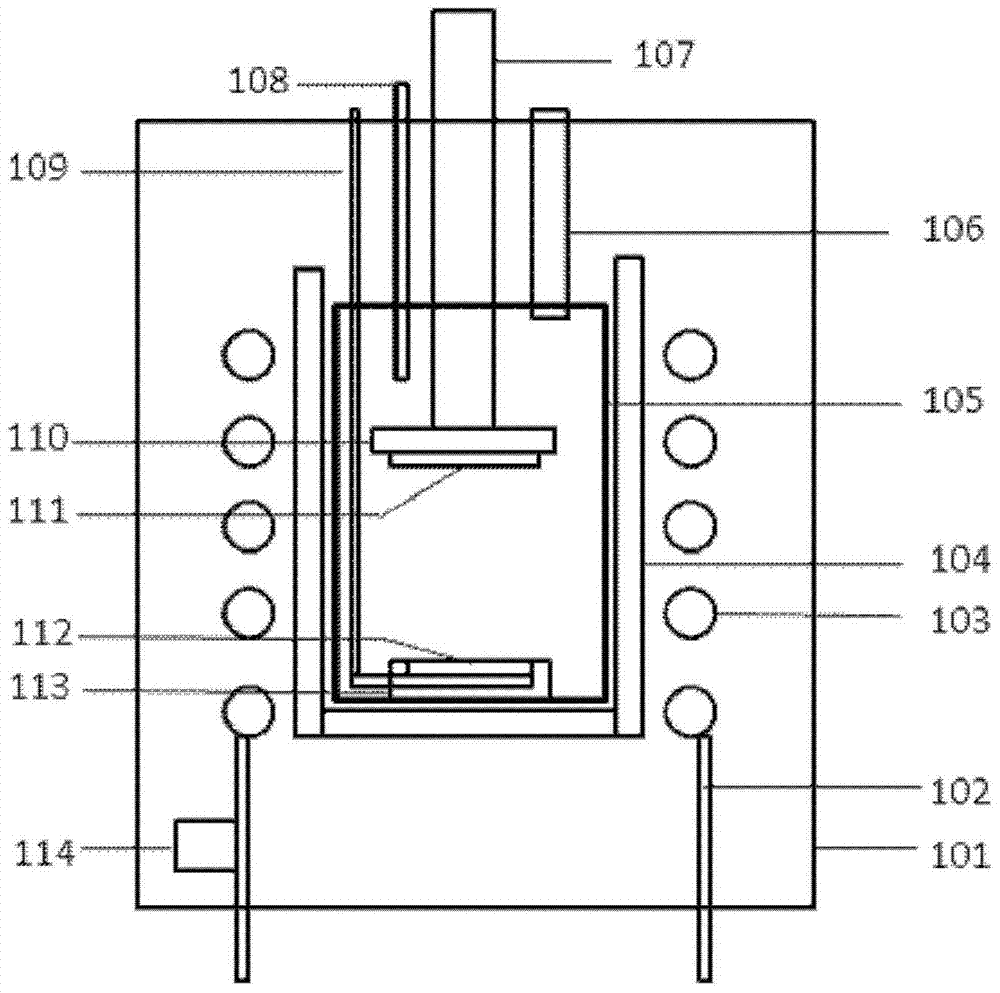

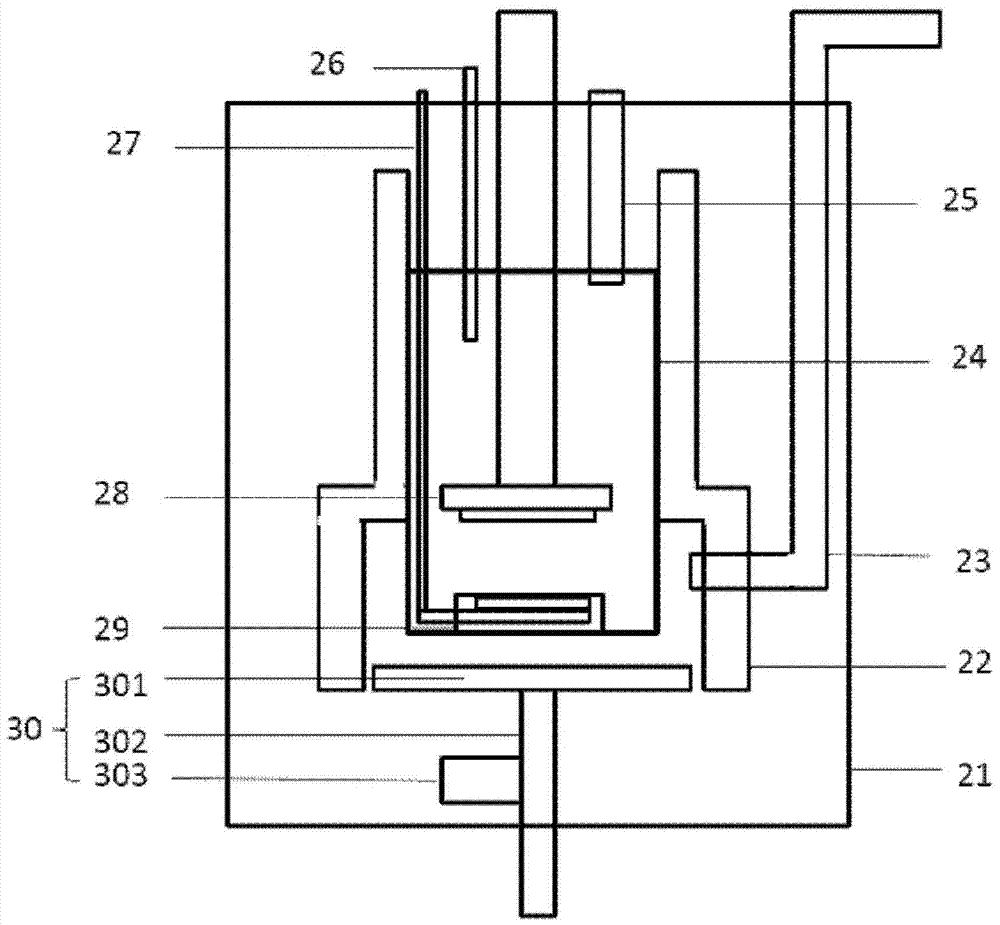

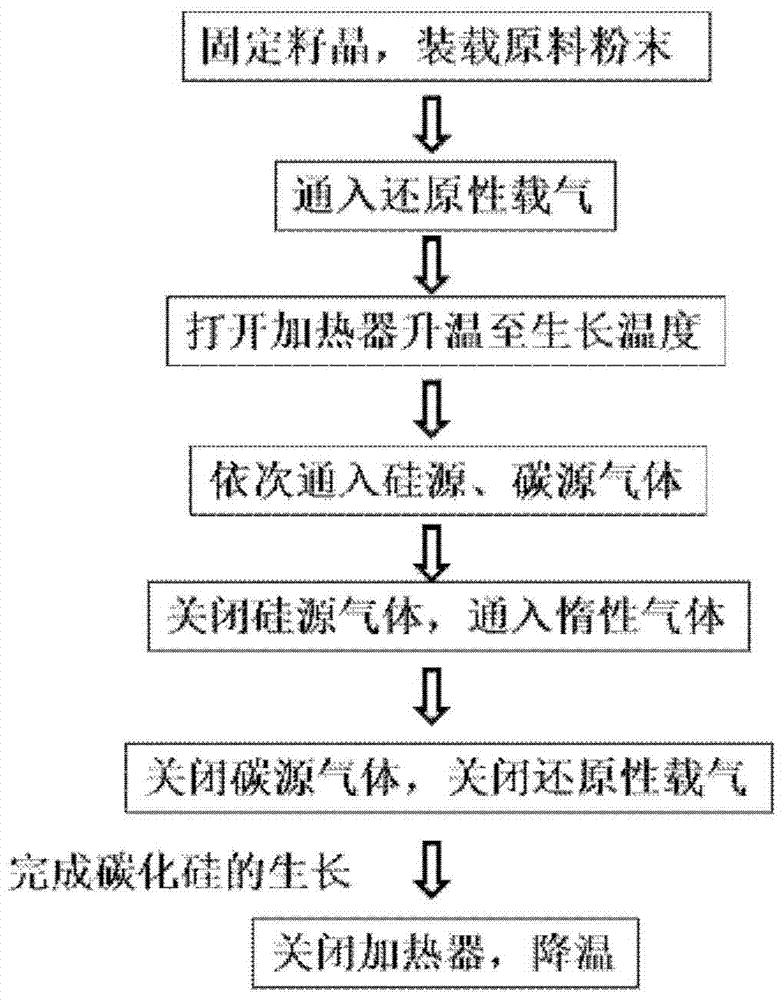

[0033] See figure 2 As shown, the present invention provides a high-temperature device for silicon carbide growth, including:

[0034] A she...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com