High-temperature liquid slag heat energy recovery device

A heat energy recovery, liquid state technology, applied in the direction of improving energy efficiency, furnace, waste heat treatment, etc., can solve the problem that the heat energy of high temperature liquid slag cannot be recovered.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

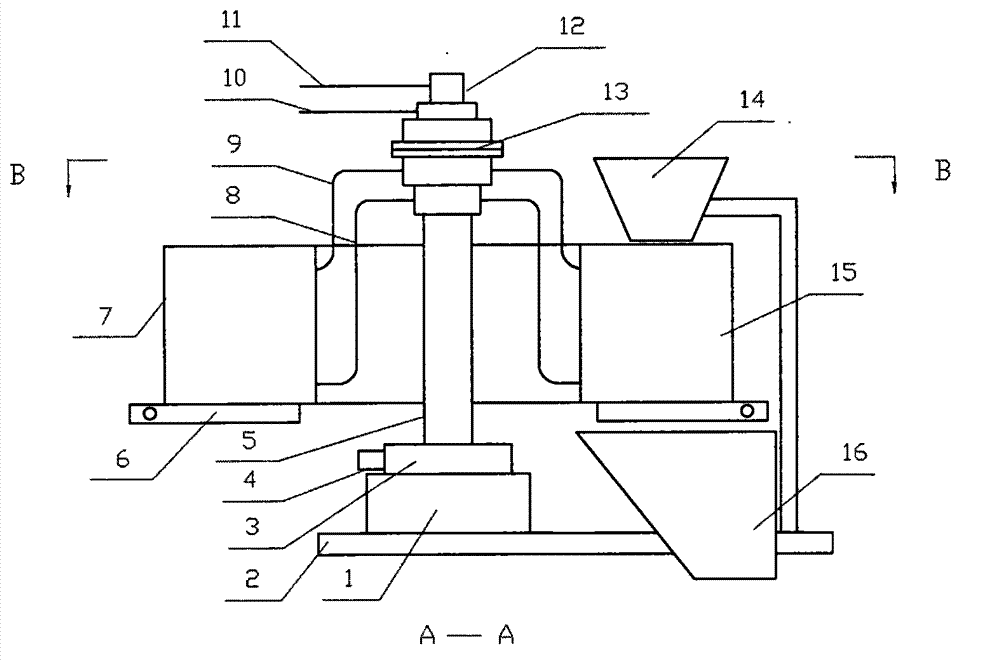

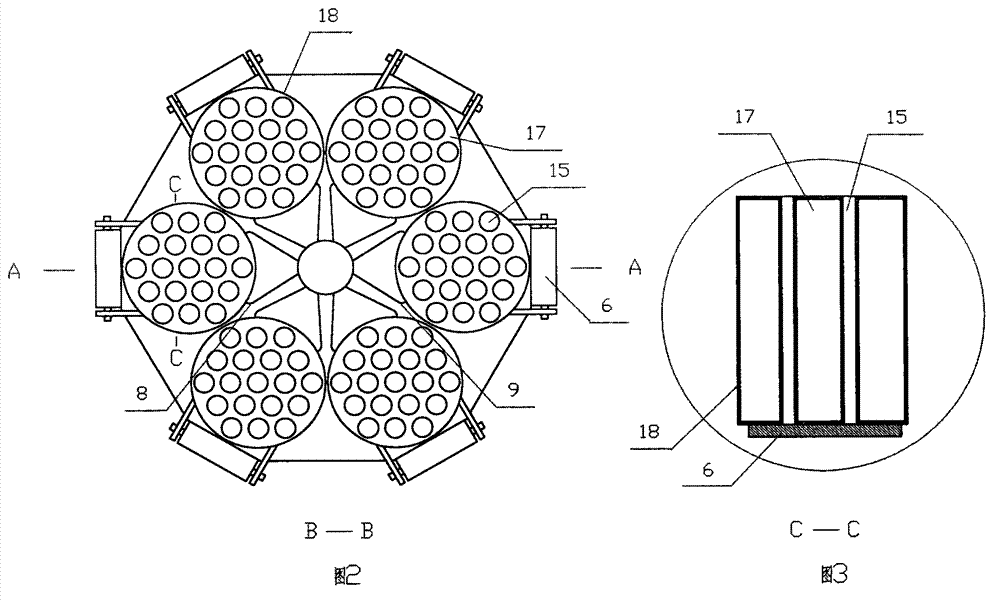

[0010] The liquid slag cooler consists of a combined bearing seat 1, a machine base 2, a reducer 3, a motor 4, a feed port 14, a discharge port 16, and a turntable 7; a combined bearing seat 1, a feed port 14, a discharge port 16, Installed on the machine base 2, the reducer 3 and the turntable 7 are installed on the combined bearing seat 1, and the motor 4 is fixed on the reducer 3. The turntable 7 is composed of a central shaft 5, a discharge valve 6, a water pipe 8, a water pipe 9, a water outlet pipe 10, a water inlet pipe 11, a rotary joint 12, a rotary joint 13, and a cooler 18; The center is evenly fixed on the central axis 5, the water inlet pipe 11 is connected to the water pipe 8 through the rotary joint 12, the water pipe 8 is connected to the inlet water pipe of the cooler 18, the outlet water pipe of the cooler 18 is connected to the water pipe 9, and the water pipe 9 is connected to the water pipe 13 through the rotary joint 13 Connected with the outlet pipe 10, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com