Sludge energy-saving drying unit and sludge energy-saving drying method

A sludge drying and sludge technology, applied in the direction of sludge treatment through temperature control, dehydration/drying/thickened sludge treatment, etc., can solve the problems of reducing the use of fresh steam, low evaporation water vapor temperature, unfavorable recovery, etc., to achieve Reduce raw steam consumption, reduce operating load, and achieve remarkable energy-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

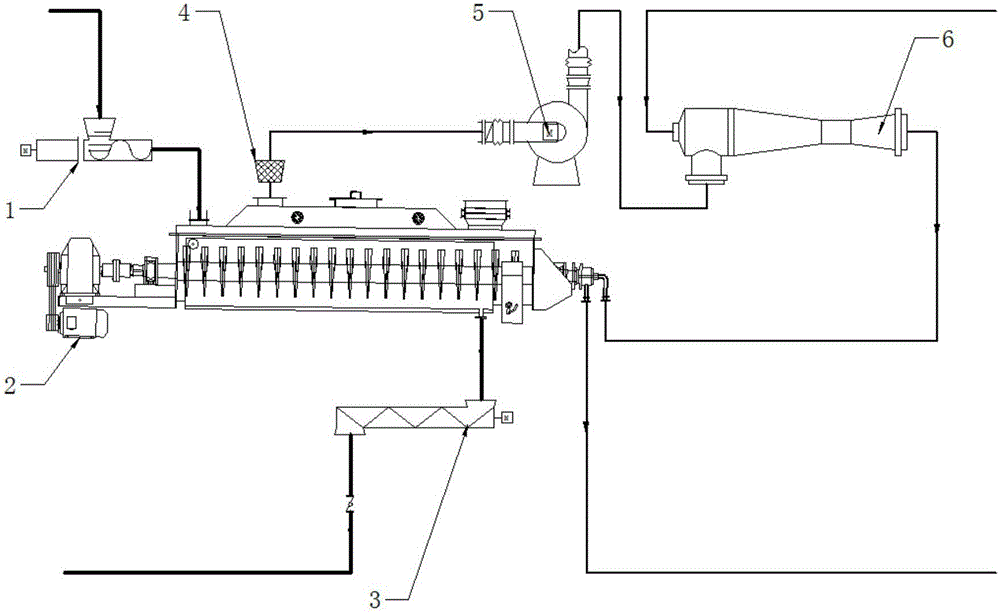

[0018] Such as figure 1 As shown, a sludge energy-saving drying treatment device in this embodiment includes a feeder 1, a sludge dryer 2 (the sludge dryer is a paddle dryer), a conveyor 3, a filter and dust removal device 4, a compressor 5 (the compressor is a centrifugal steam compressor), a pressurized mixer 6 (the pressurized mixer is a steam jet heat pump). Wherein the feeder is connected with the feed inlet above the paddle dryer; the outlet below the paddle dryer is connected with the conveyor; The air outlet of the dust removal device is connected with the inlet of the centrifugal steam compressor; the outlet of the centrifugal steam compressor is connected with the inlet of the steam jet heat pump; the outlet of the steam jet heat pump is connected with the inlet of the paddle dryer.

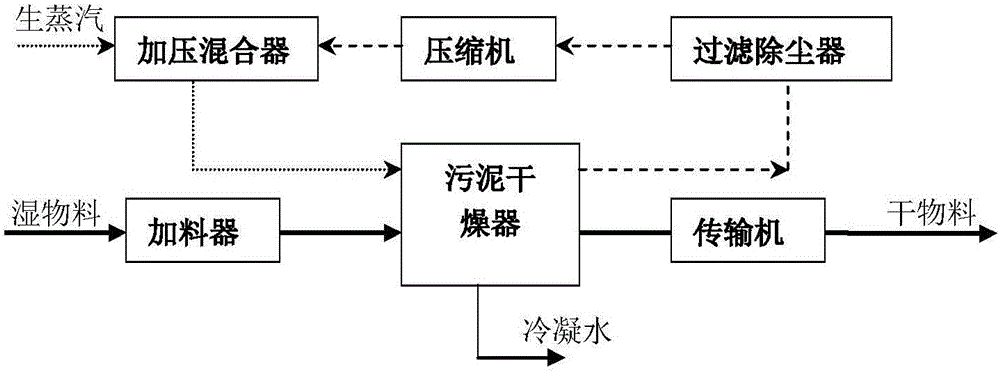

[0019] Such as figure 2 As shown, a sludge energy-saving drying treatment method includes the following steps: transporting the wet sludge to a paddle dryer through a feeder for dehy...

Embodiment 2

[0022] Such as figure 1 As shown, a sludge energy-saving drying treatment device in this embodiment includes a feeder 1, a sludge dryer 2 (the sludge dryer is a paddle dryer), a conveyor 3, a filter and dust removal device 4, a compressor 5 (the compressor is a Roots-type steam compressor), and the pressurized mixer 6 (the pressurized mixer is a steam jet heat pump). Wherein the feeder is connected with the feed inlet above the paddle dryer; the outlet below the paddle dryer is connected with the conveyor; The air outlet of the dust removal device is connected to the inlet of the Roots-type steam compressor; the outlet of the Roots-type steam compressor is connected to the inlet of the steam jet heat pump; the outlet of the steam jet heat pump is connected to the inlet of the paddle dryer.

[0023] A sludge energy-saving drying treatment method, comprising the following steps: transporting the wet sludge to a paddle dryer through a feeder for dehydration and drying treatment,...

Embodiment 3

[0026] Such as figure 1 As shown, a sludge energy-saving drying treatment device in this embodiment includes a feeder 1, a sludge dryer 2 (the sludge dryer is a vacuum disc dryer), a conveyor 3, a filter and dust removal device 4, a compressor 5 (the compressor is a centrifugal steam compressor), a pressurized mixer 6 (the pressurized mixer is a steam jet heat pump). Wherein the feeder is connected with the feed port above the vacuum disc dryer; the discharge port below the vacuum disc dryer is connected with the conveyor; The air outlet of the dust removal device is connected with the inlet of the centrifugal steam compressor; the outlet of the centrifugal steam compressor is connected with the inlet of the steam jet heat pump; the outlet of the steam jet heat pump is connected with the inlet of the vacuum disc dryer.

[0027] An energy-saving drying treatment method for sludge, comprising the following steps: transporting wet sludge to a vacuum tray dryer through a feeder f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com