Tempering furnace with foot case

A technology for tempering furnaces and footboxes, which is applied in household furnaces/stoves, lighting and heating equipment, solid heating fuels, etc. It can solve the problems of no comprehensive utilization of energy, achieve good heating effects, extend the flue process, and improve fuel utilization rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

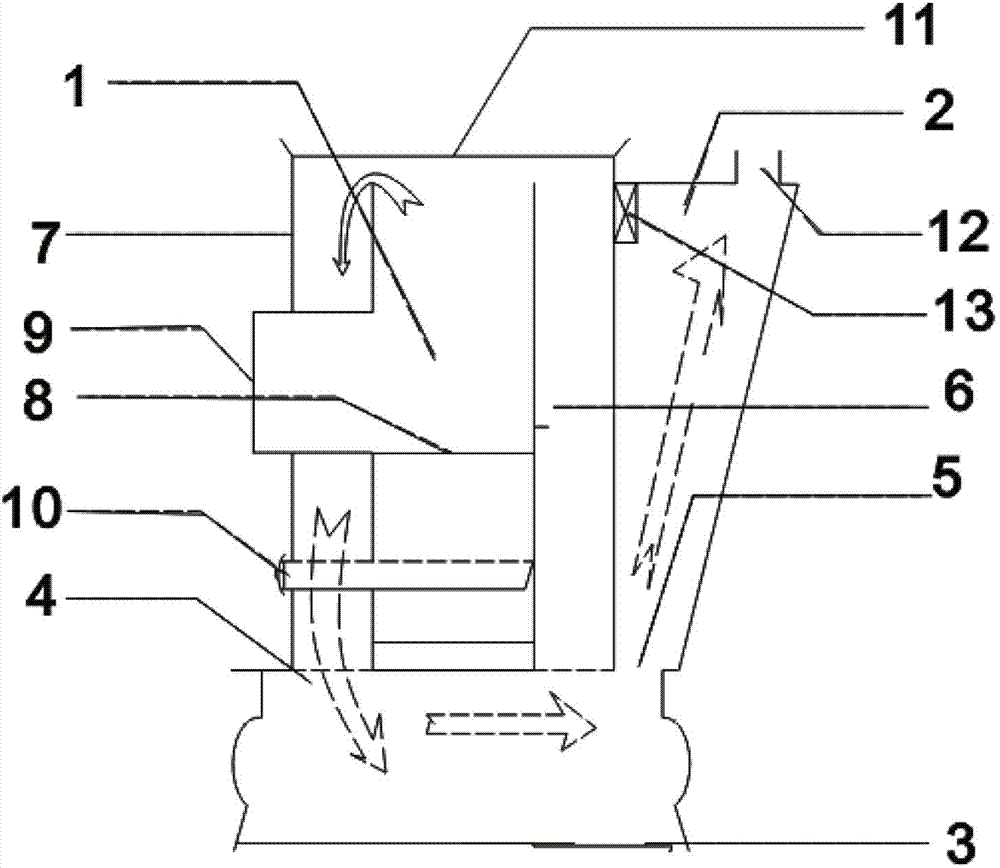

[0014] A foot box tempering furnace, comprising a furnace body 1, a smoke box 2, and a foot box 3, wherein the foot box 3 communicates with the furnace body tempering passage through the foot box flue gas inlet 4, and the smoke box 2 communicates with the furnace body through the foot box flue gas outlet 5 Foot box 3 communicates.

[0015] The furnace body 1 is also provided with an inner container 6 and an outer cylinder 7, the outer cylinder 7 and the inner container 6 form an interlayer, the interlayer space communicates with the foot box 3, and the foot box 3 is in a sealed state.

[0016] Also be provided with furnace bridge 8 in described liner 6, furnace bridge 8 is provided with furnace door 9 and ash hopper 10 up and down respectively.

[0017] The foot box 3 can be a circular or square or polygonal box body, and its void volume is larger than the tempering channel formed by the outer cylinder 7 and the inner container 6 .

[0018] The top of the outer cylinder 7 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com