Anti-frosting structure of air conditioner of automobile

A car air conditioner and anti-frost technology, applied in damage protection, space heating and ventilation, heating methods, etc., can solve problems such as air-conditioning failure, resource waste, and reduced car comfort, so as to prevent frost and reduce resource waste , the effect of comfortable temperature environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

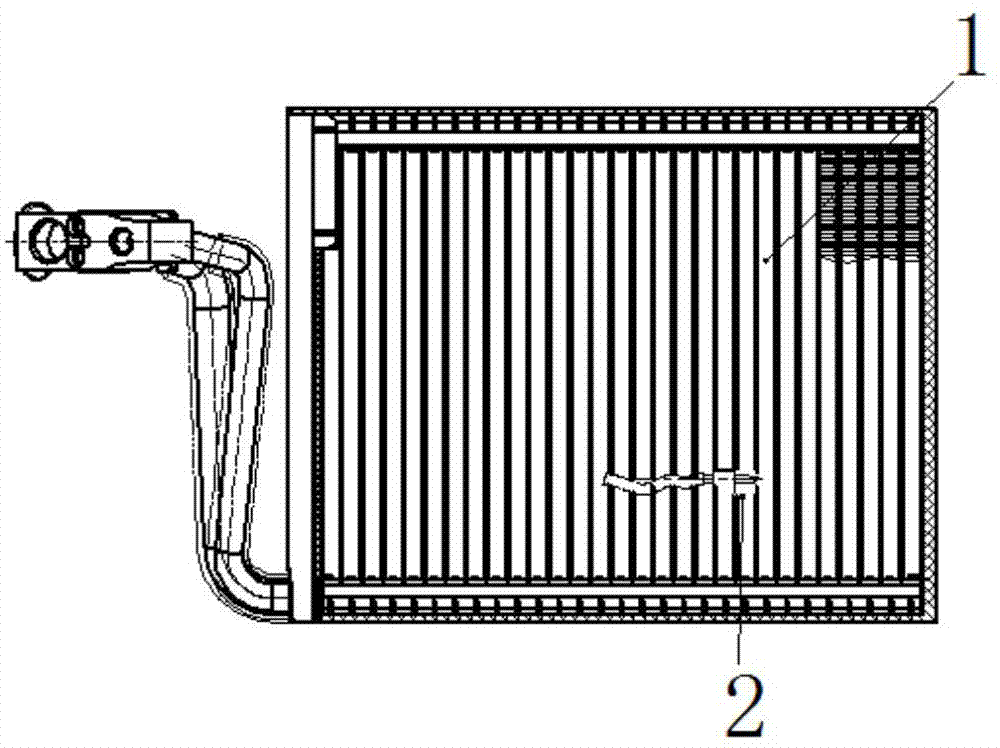

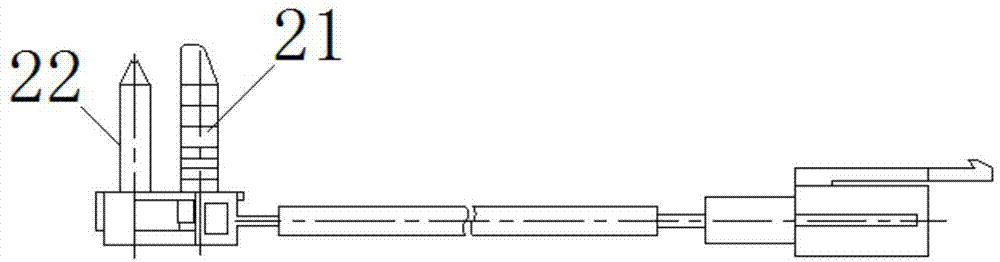

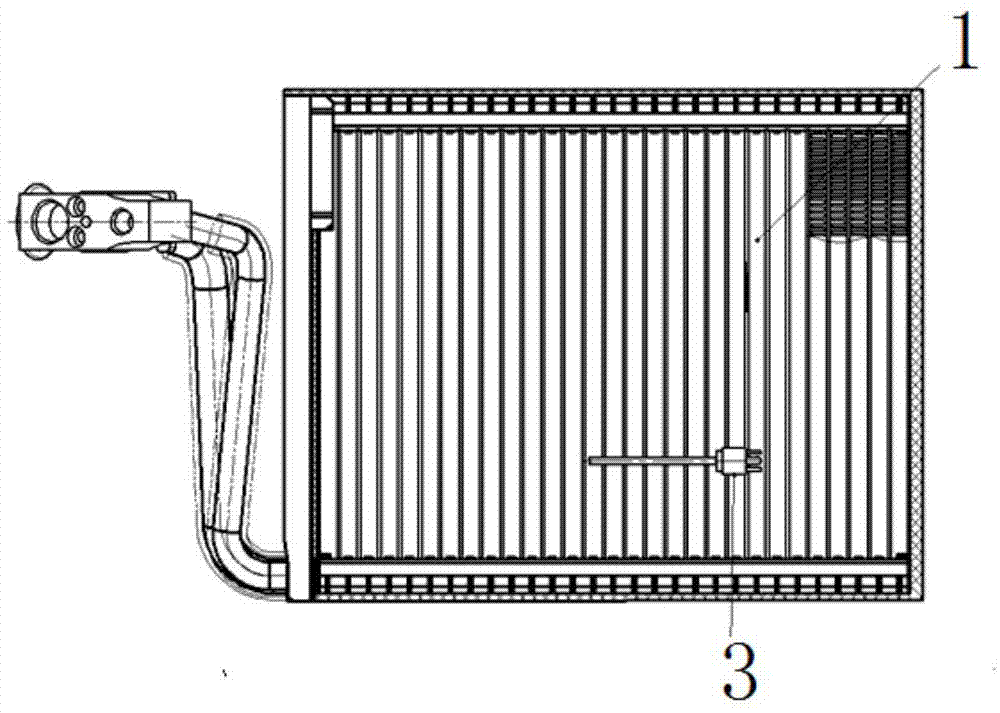

[0017] Such as figure 1 and figure 2 As shown, the automobile air conditioner anti-frost structure includes an evaporator core 1 and a plug-in temperature sensor 2, wherein the plug-in temperature sensor includes a sensor stem 21 and a positioning column 22, and the sensor stem 21 of the plug-in temperature sensor is inserted into The interior of the evaporator core body 1 is inserted into the interior of the evaporator core body through the positioning column for positioning and fixing.

[0018] The positioning column 22 and the sensor stem 21 are arranged side by side, and the ends of the positioning column and the sensor stem are provided with a guide structure for easy insertion into the evaporator core. Preferably, the end of the positioning column is provided with a tapered surface, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com