Simple device for testing surface slide angles of fabrics

A sliding angle and fabric technology, applied in measuring devices, adopting mechanical devices, analyzing materials, etc., can solve problems such as expensive refitting costs, and achieve the effects of low cost, strong practicability, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

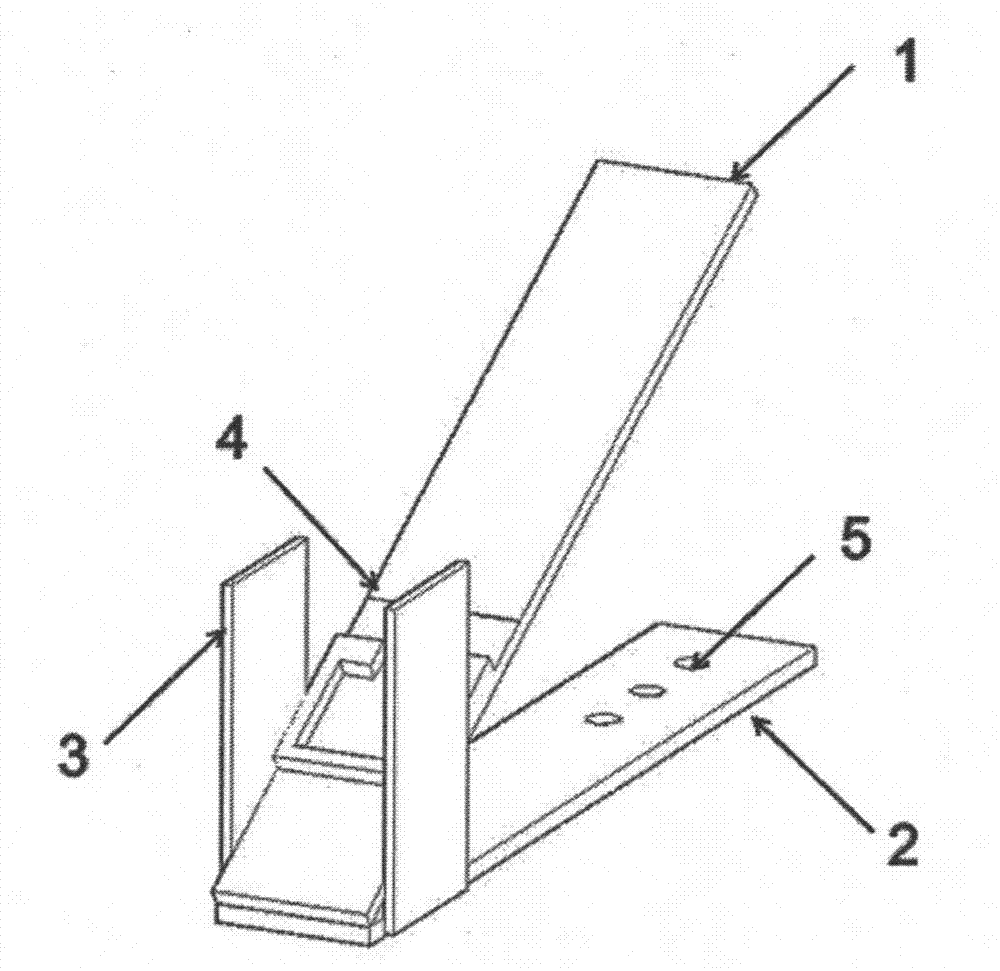

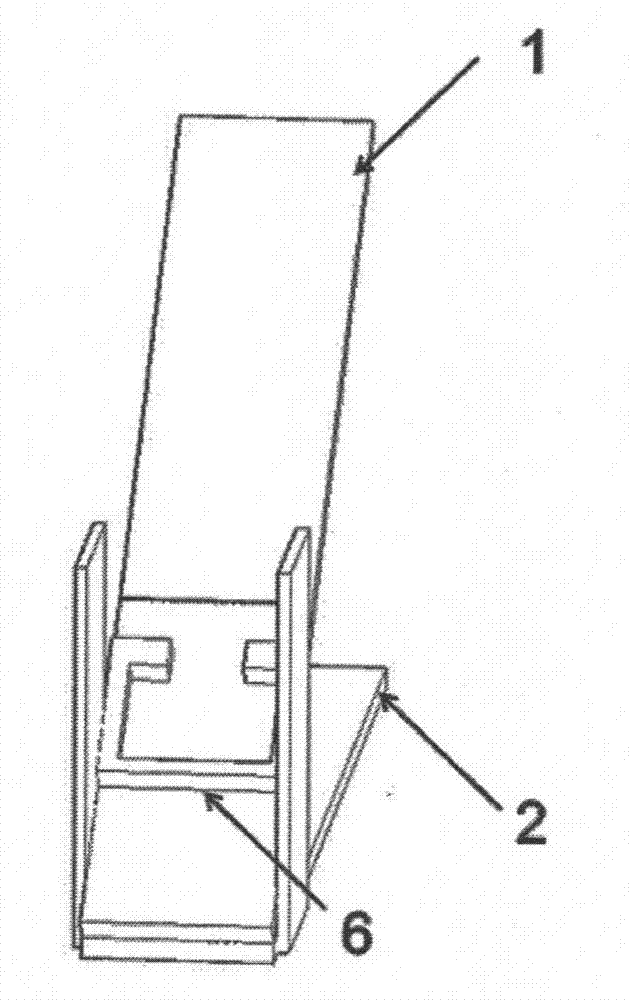

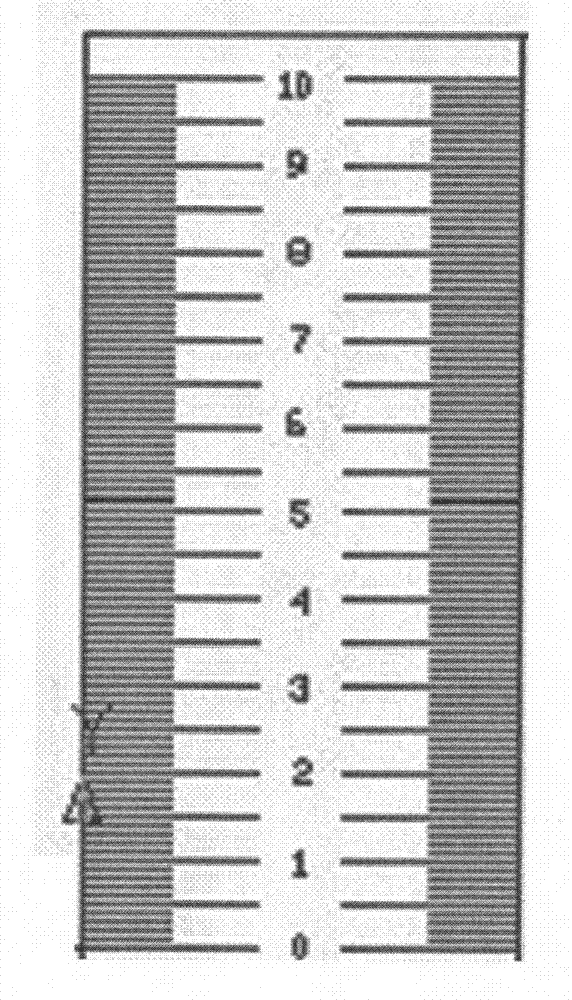

Embodiment 1

[0031] In this preferred embodiment, the OCA20 video contact angle meter of German Dataphysics Company and this device complete the sliding angle test of a piece of super-hydrophobic fabric. Take the ruler width as 50mm. Cut the fabric into a test sample with a length of 5 cm and a width of 2 cm, and glue it on a glass slide with double-sided tape. One end of the test sample is parallel to and coincides with one end of the glass slide. Place the glass slide above the water tank 6 on the sample plate 1 . Place the device onto the platform of the OCA20. Use a microsyringe to inject 15 μl of water at a distance of 20 mm from the bottom of the sample (that is, the position indicated by the scale line). According to experience, injecting 3 μl again after the injection is terminated can make the water drop out of the needle. Then slowly lift the free end of the sample plate 1 by hand screwing. Observe the water droplet on the sample, when the water droplet starts to slide, it is ...

Embodiment 2

[0033] In this preferred embodiment, the OCA20 video contact angle meter of German Dataphysics Company and this device complete the sliding angle test of a piece of super-hydrophobic fabric. Take the ruler width as 80mm. Cut the fabric into a test sample with a length of 5 cm and a width of 2 cm, and glue it on a glass slide with double-sided tape. One end of the test sample is parallel to and coincides with one end of the glass slide. Place the glass slide above the water tank 6 on the sample plate 1 . Adjust the device to the maximum angle and place it on the platform of OCA20. Adjust the height of the platform so that the vertical distance between the indicator line 4 of the glass slide and the needle of the syringe is 1 cm, use a micro-syringe to inject 15 μl of water at a distance of 20 mm from the bottom of the sample (that is, the position indicated by the scale line), and according to experience, after the injection is terminated, inject 15 μl of water. Injecting 3 μ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com