Corn directional sowing system and directional sowing method

A corn and control system technology, applied in the field of agricultural machinery, can solve problems such as high labor intensity, immature technology, and low production efficiency, and achieve the effects of improving efficiency and quality, reducing seed damage, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Taking corn sowing as an example to illustrate the implementation process of the system.

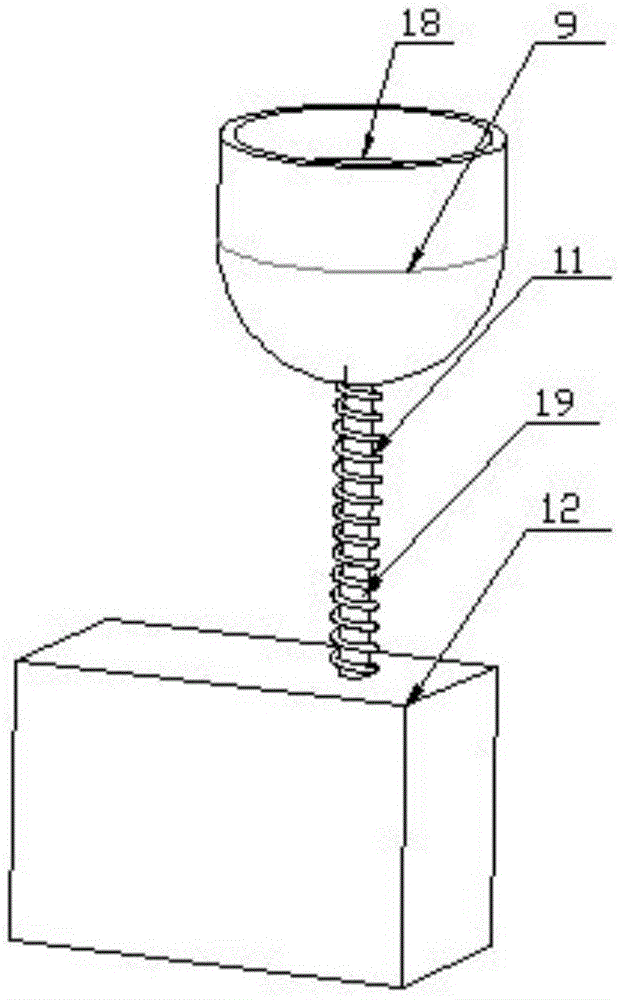

[0045] The directional seeding system includes a vibrating screening system and a single-grain seeding system. The vibrating screening system adopts the existing technology, and the single-grain seeding system adopts an air-suction precision seeder. The vibrating screening system screens corn kernels, filters out damaged and smaller corn kernels, and retains excellent corn kernels to ensure the survival rate of corn; the single-seed seeding system sorts the corn under the action of external force, There will be a small baffle at the end of the seeding mechanism, through which the corn is isolated to ensure that only one corn kernel can pass through the seed discharge port of the single seed metering system at a time.

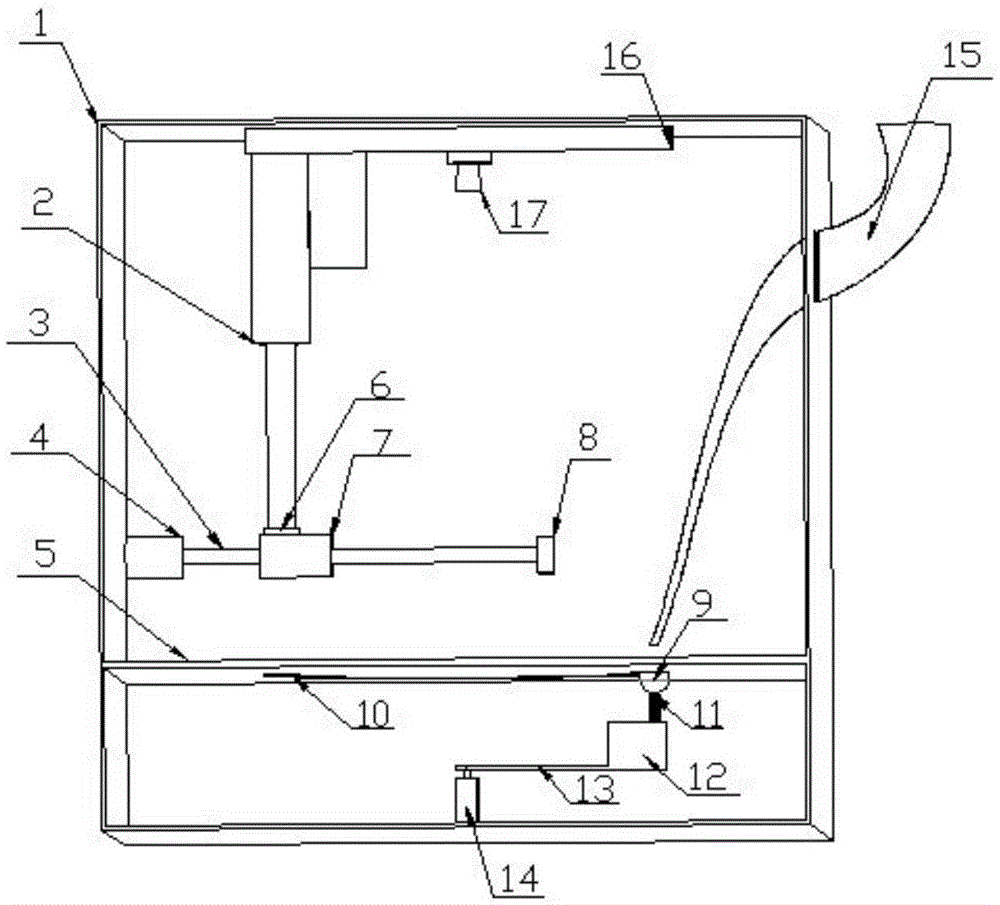

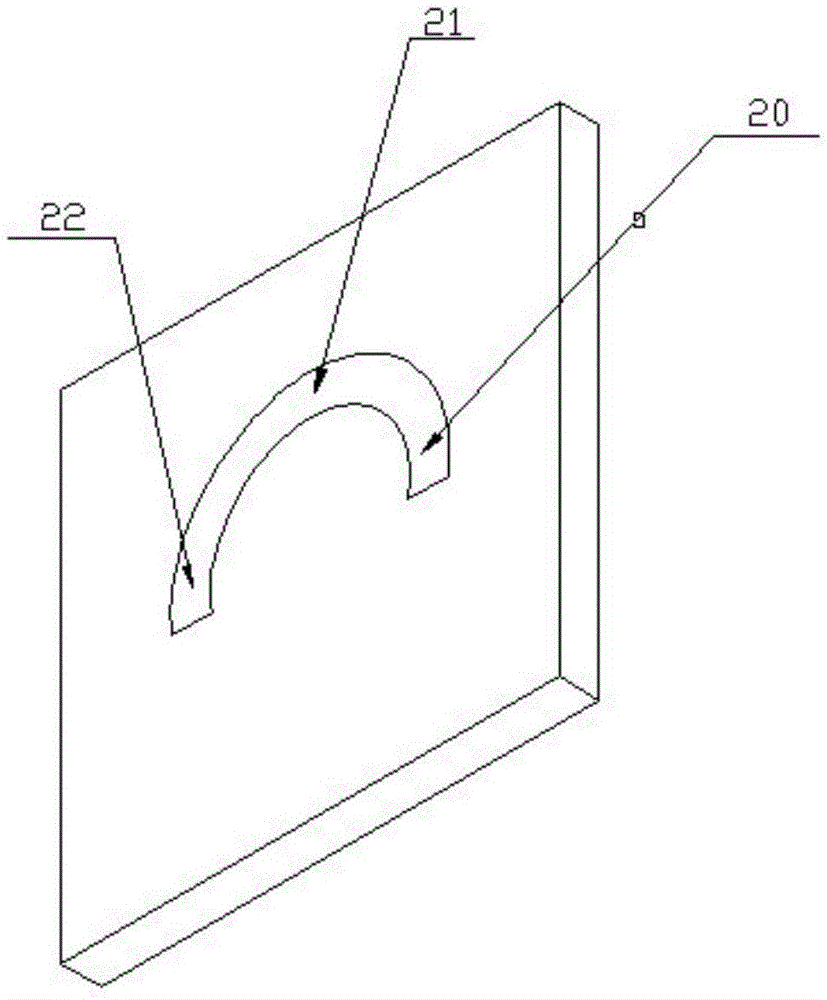

[0046] The directional sowing system also includes a control system 23, a dark box 1, and a delivery channel 15. An image recognition system, a rotating mechanism a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com