Explosive-handling robot

A technology of EOD robot and mechanical arm, which is applied in the direction of manipulators, chucks, manufacturing tools, etc., can solve the problems of high cost, price of hundreds of thousands to millions, restrictions on the promotion of EOD robots, and complex price structure, etc., to achieve Effects of saving materials, avoiding structures and components, good gradeability and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

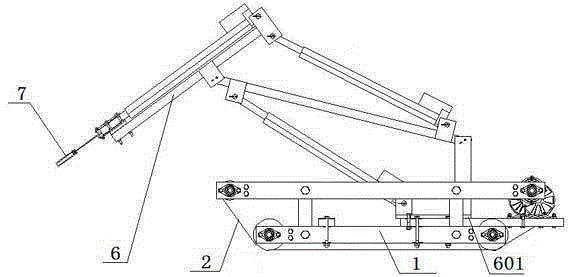

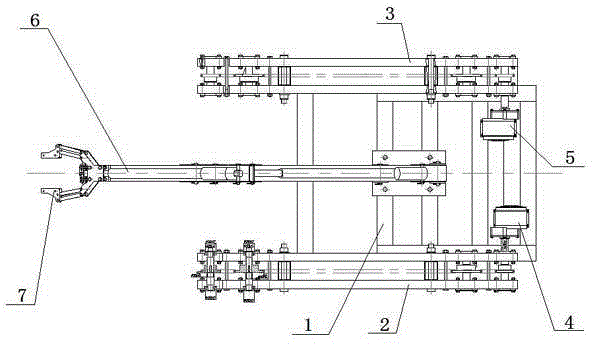

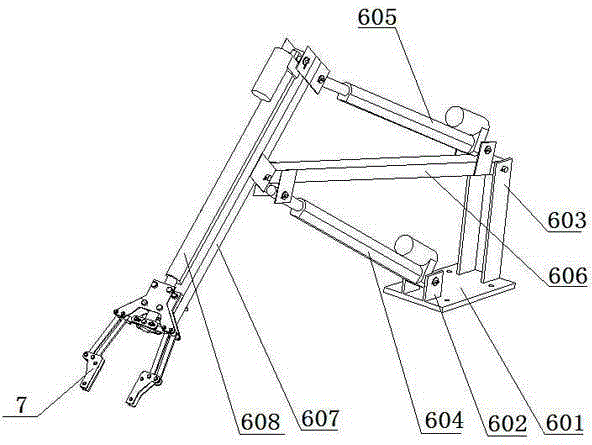

[0025] see Figure 1 to Figure 4 , the EOD robot of the present invention includes a chassis 1, a left crawler 2, a right crawler 3, a left motor 4, a right motor 5, a mechanical arm 6, and a manipulator 7; the left crawler 2 and the right crawler are respectively arranged on both sides of the chassis 1 3. The left crawler belt 2 is linked with the left motor 4, and the right crawler belt 3 is linked with the right motor 5; the mechanical arm 6 is fixedly installed on the chassis 1, and the mechanical arm 7 is installed at the end of the mechanical arm 6.

[0026] The robot can realize the following actions during motion: forward, backward, turning and speed change, with good response characteristics. in: Robot variable speed movement: Accelerate or decelerate the click through current control; Robot driving: The robot is additionally equipped with a CCD camera, and the operator can adjust the direction of the EOD vehicle at a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com