Side wall sealing type deep hole structure and mold thereof, and injection molding method of mold

A closed, deep-hole technology, used in other household appliances, household appliances, household components, etc., can solve problems such as appearance defects, inability to solve surface air trapping, etc., to achieve the effect of low cost, easy implementation, and simple mold structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

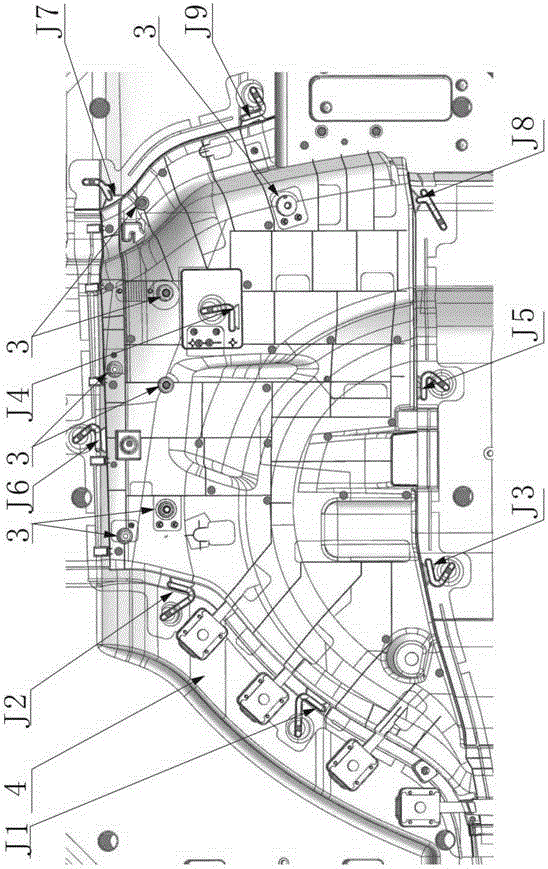

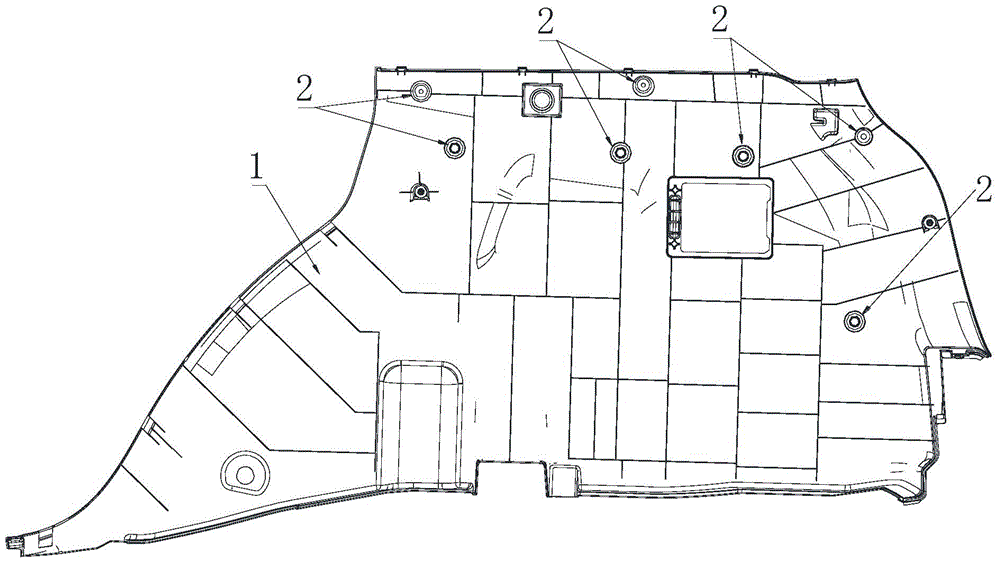

[0044] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

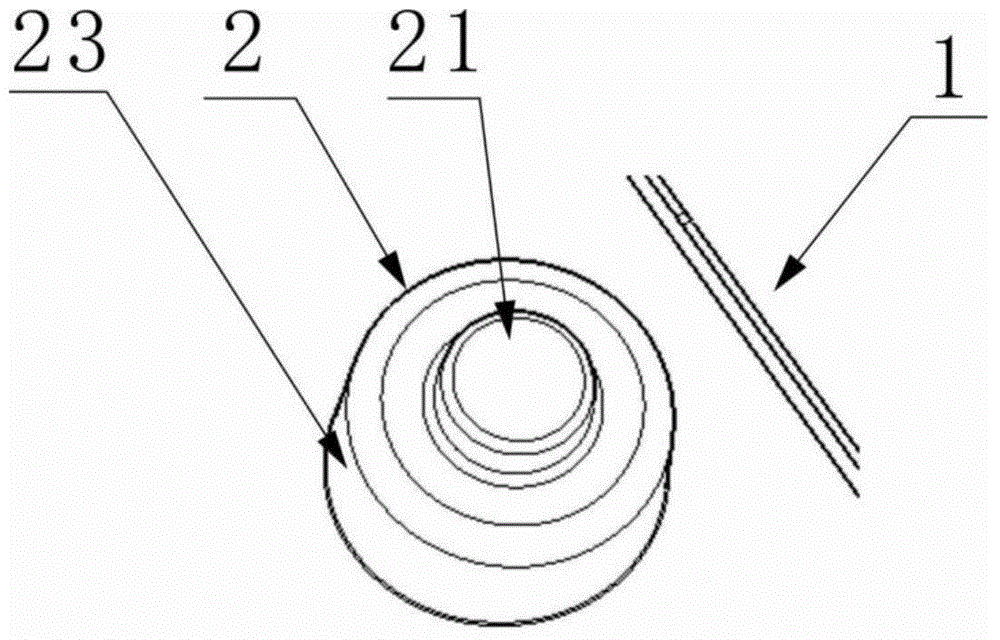

[0045] like Figure 9 Shown in the figure is the improved deep hole structure 2 of the first structure. The difference from that before the improvement is that: glue-reducing and flow-restricting structures 24 are respectively added to the sidewalls 23 of the holes on both sides relative to the material flow direction.

[0046] like Figure 10 As shown, the role of the glue reducing and flow limiting structure 24 is to slow down the forward speed of the C stream, and allow the AB streams to continue to flow to the hole side wall 23 behind the injection direction to form the D stream after the normal confluence of the AB streams, and finally make the C stream , D streams converge at the top of the deep hole structure 2 . The top of the deep hole structure 2 is exactly where the exhaust insert of the exhaust mechanism is located, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com