Pressure-maintaining hot runner nozzle

A technology of hot runner nozzles and runners, which is applied in the field of hot runner nozzles with pressure-holding function, and can solve the problems of reduced density of plastic melt, poor local mechanical properties of parts, limited sealing and pressure-holding performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

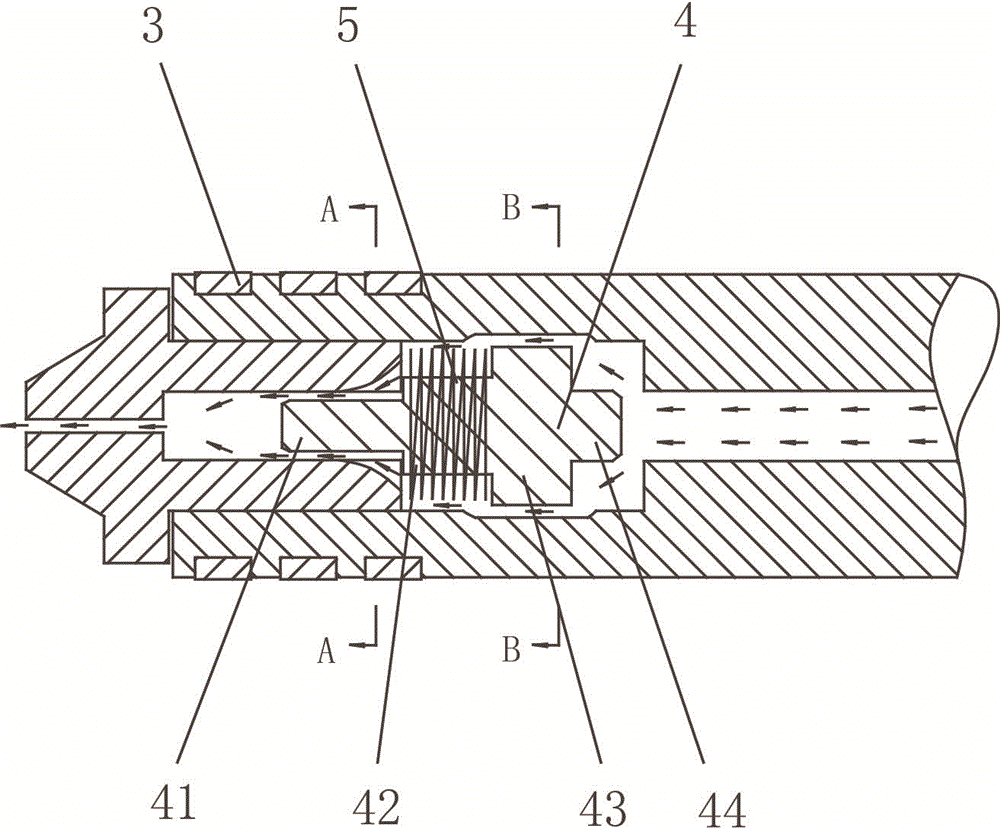

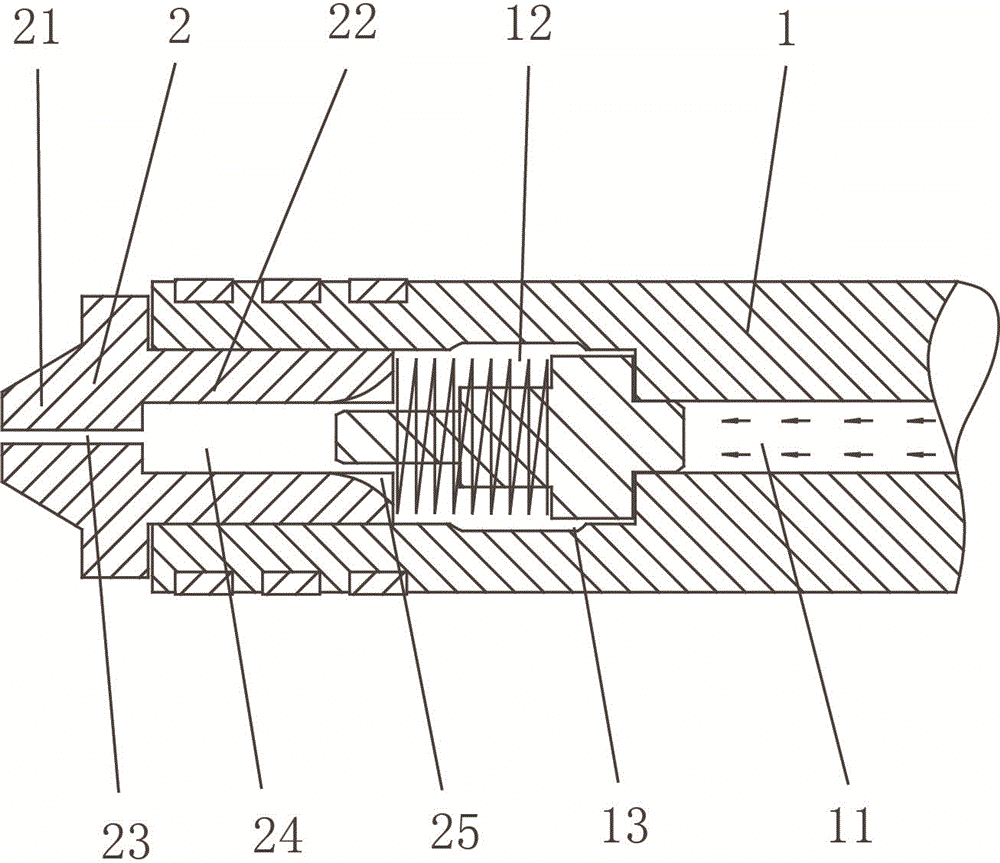

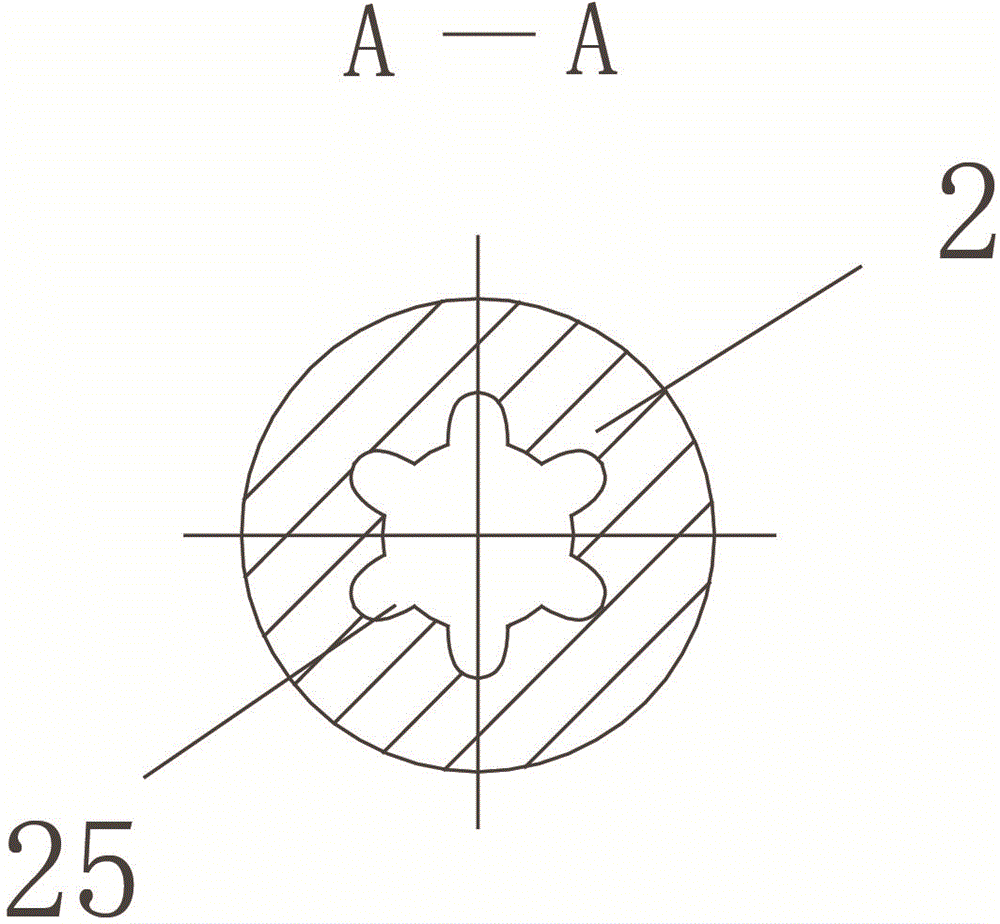

[0014] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment: see Figure 1~4 As shown in the figure, marked as follows: flow channel cylinder (1), injection channel (11), liquid storage cavity (12), groove (13), nozzle (2), nozzle head (21), casing (22), injection port (23), liquid cavity (24), oblique notch (25), heating element (3), plunger (4), first step column (41), second step column (42 ), the third step post (43), the fourth step post (44), spring (5).

[0015] A hot runner nozzle with pressure maintaining function, including a flow channel column 1 and a nozzle 2, the center of the flow channel column 1 is provided with an injection channel 11 and a liquid storage cavity 12, and the nozzle 2 includes a nozzle head 21 and a sleeve 22. The casing 22 is threadedly connected to the inner wall of the liquid storage cavity 12, the nozzle head 21 is provided with an injection port 23, the center of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com