Dedicated measuring instrument for shield grease water-resistant sealing and test method thereof

A technology of measuring instrument and test method, applied in the field of lubricating grease, can solve the problems of large test error, unsatisfactory, complicated operation, etc., achieve the effect of small test error, ensure uninterrupted operation, and reduce operation difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

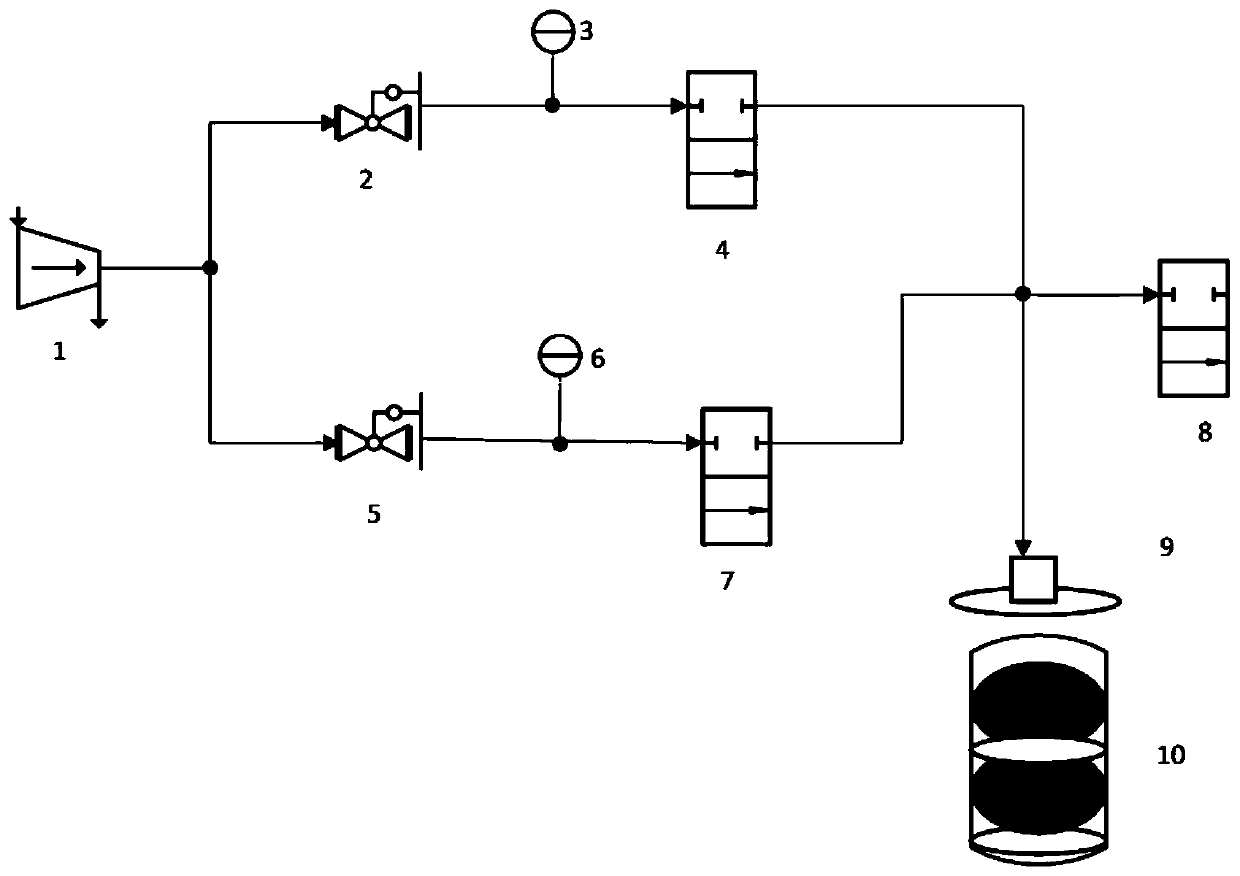

Method used

Image

Examples

Embodiment 1

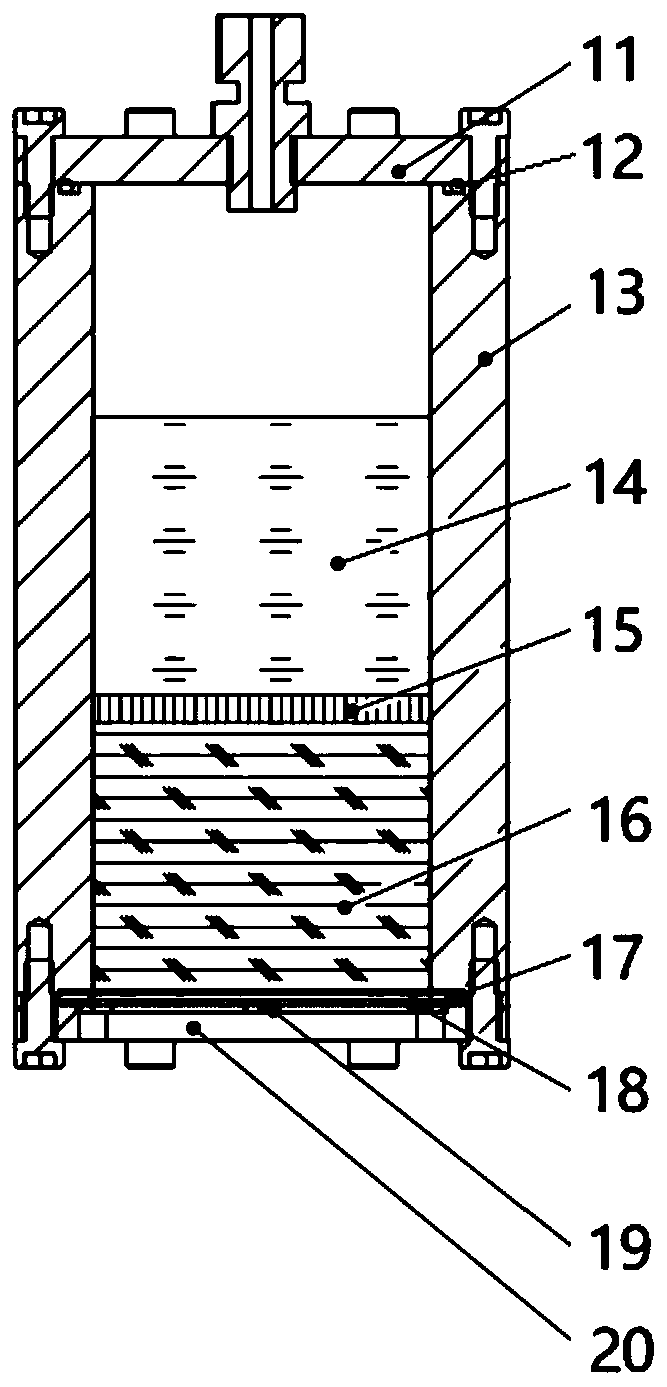

[0031] Place two layers of 20-mesh test sieve plates on the bottom of the test cylinder, fix the lower sealing cover, and then weigh 102g of commercially available shield tail sealant A into the test cylinder. The sample was compacted with a 20-mesh flattened sieve. Inject 102g of pure water into the test cylinder. Fix the sealing cover and install the sealing joint.

[0032] The high-pressure nitrogen gas source was set to provide a pressure of 4.5 MPa. Adjust the pressure regulating valve of pipeline A to make the pressure of the pressure transmitter of pipeline A reach 0.5MPa. The switch solenoid valve of pipeline A is energized to open, and the switch solenoid valve of pipeline B is in a power-off state at this time. Set the test time to 300s, and start the first constant pressure test. Before the end of the first test, the pressure of pipeline B is set to 1.0MPa. After the first constant pressure test is over, the switch solenoid valve of pipeline A is closed, and th...

Embodiment 2

[0037] Place a layer of 200-mesh test sieve plate at the bottom of the test cylinder, fix the lower sealing cover, and then weigh 100g of commercially available main bearing sealant grease A into the test cylinder. The sample was compacted with a 200-mesh flattened sieve. Inject 100g of pure water into the test cylinder. Fix the sealing cover and install the sealing joint.

[0038] Set the high-pressure air source to provide a pressure of 4.0 MPa. Adjust the pressure regulating valve of pipeline A to make the pressure of the pressure transmitter of pipeline A reach 0.5MPa. The switch solenoid valve of pipeline A is energized to open, and the switch solenoid valve of pipeline B is in a power-off state at this time. Set the test time to 60s, and start the first constant pressure test. Before the end of the first test, the pressure of pipeline B is set to 1.0MPa. After the first constant pressure test is over, the switch solenoid valve of pipeline A is closed, and the switch...

Embodiment 3

[0043] Place two layers of 30-mesh test sieve plates on the bottom of the test cylinder, fix the lower sealing cover, and then weigh 98g of commercially available shield tail sealant B into the test cylinder. The sample was compacted with a 30-mesh flattened sieve. Inject 98g of pure water into the test cylinder. Fix the sealing cover and install the sealing joint.

[0044] The high-pressure nitrogen gas source was set to provide a pressure of 5.0 MPa. Adjust the pressure regulating valve of pipeline A to make the pressure of the pressure transmitter of pipeline A reach 0.5MPa. The switch solenoid valve of pipeline A is energized to open, and the switch solenoid valve of pipeline B is in a power-off state at this time. Set the test time to 240s, and start the first constant pressure test. Before the end of the first test, the pressure of pipeline B is set to 1.0MPa. After the first constant pressure test is over, the switch solenoid valve of pipeline A is closed, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com