Starting of pressure-maintaining corer sealing valve controlled by torsion spring

A core remover and valve technology, which is applied in the direction of lifting valves, valve devices, engine components, etc., can solve the problems of unable to maintain pressure, occupy a large space, and complex ball valve structure, so as to improve the anti-deformation ability, improve the pressure holding ability, Reliable effect of sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

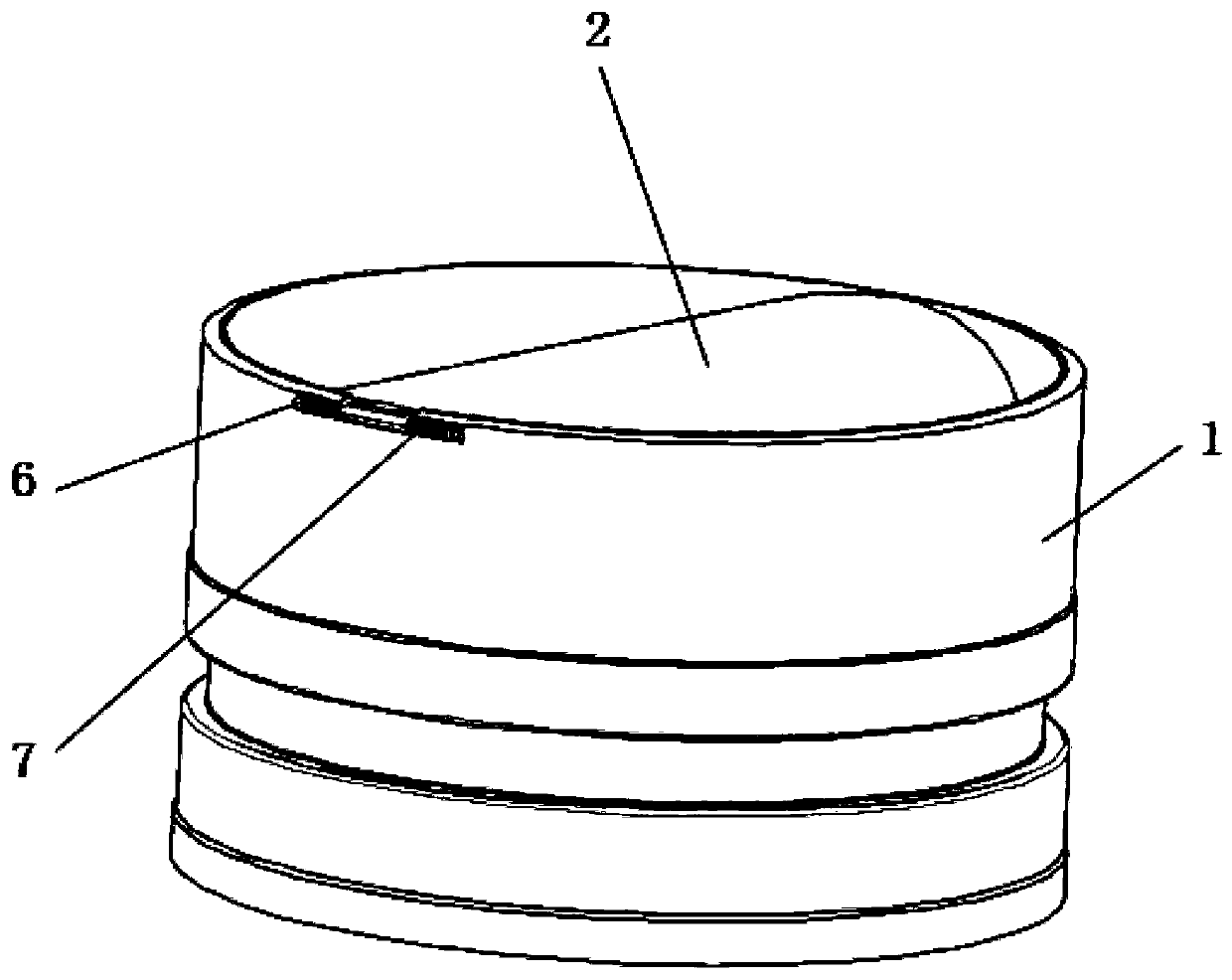

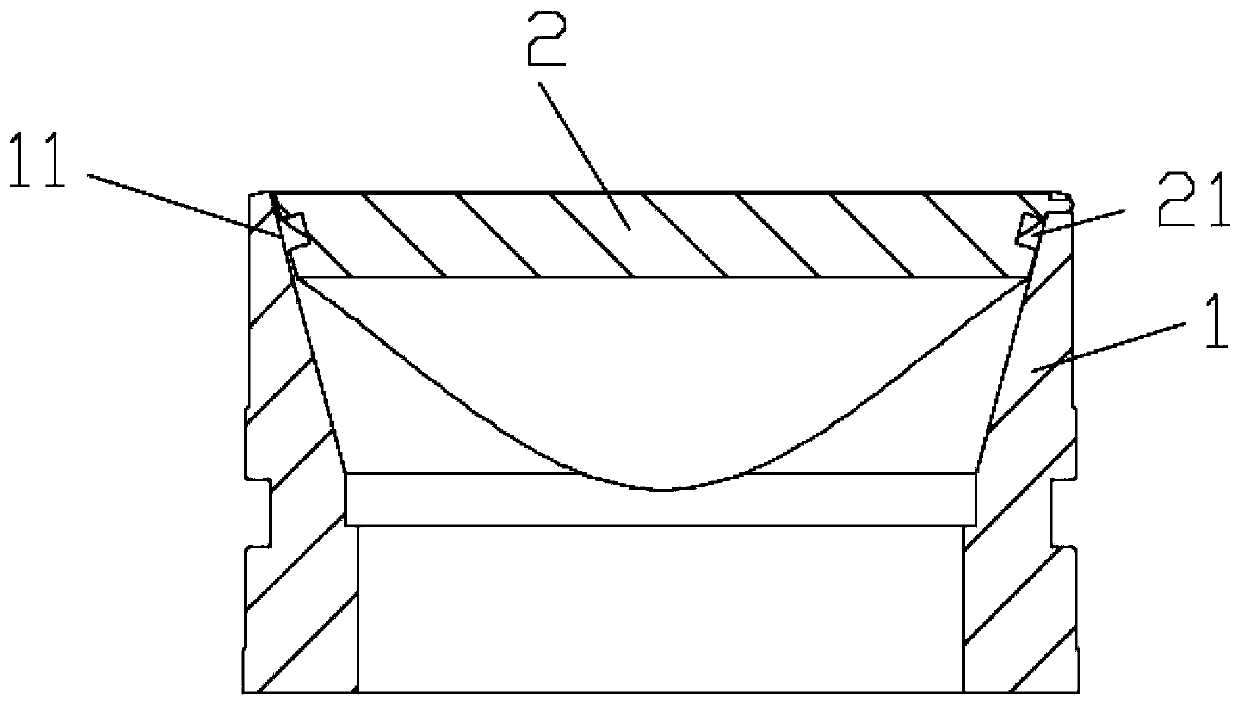

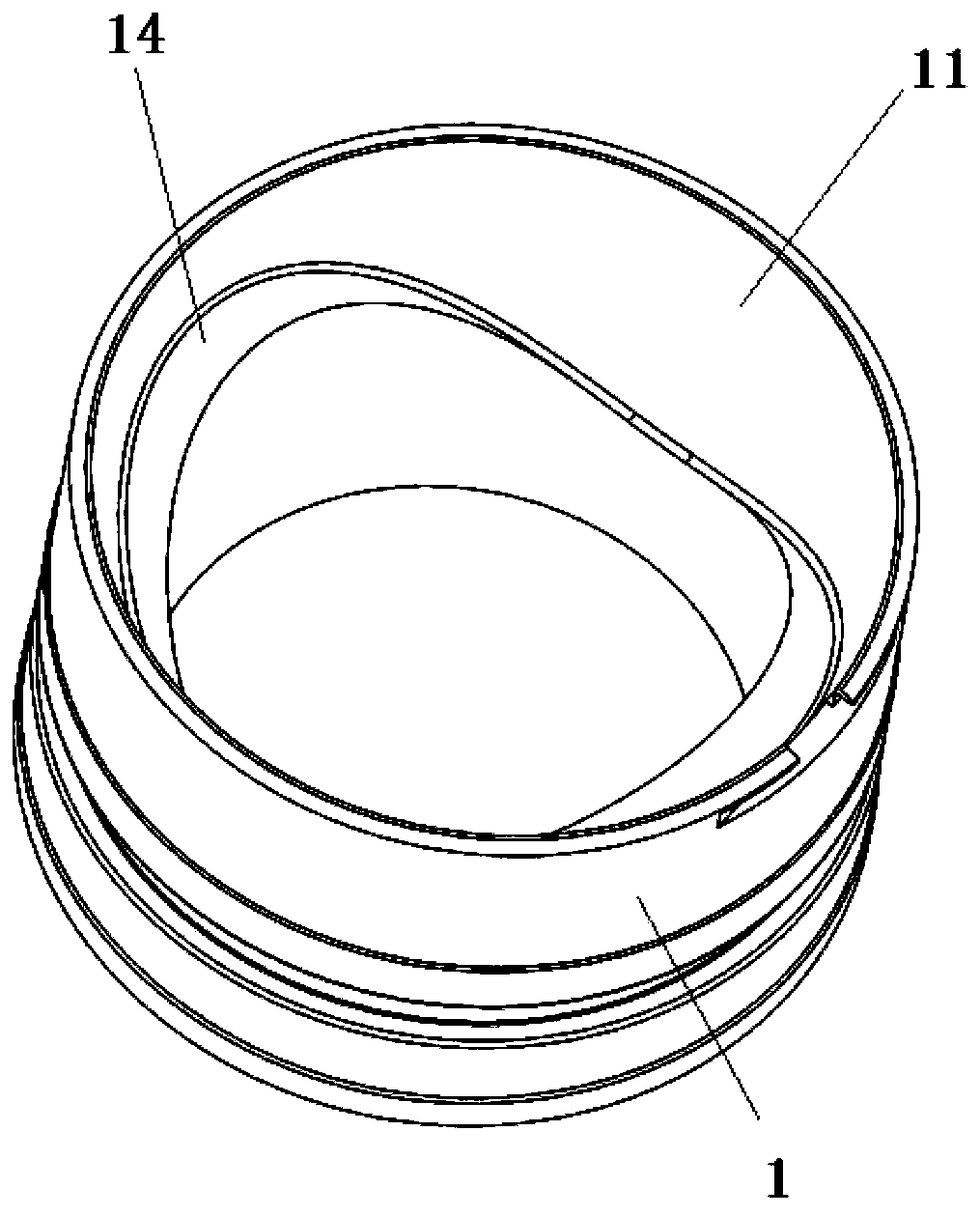

[0036] Such as figure 1 , 2 As shown, the sealing valve of the pressure-maintaining coring device disclosed in this embodiment, which is controlled by a torsion spring, includes a flap valve. The flap valve includes a valve seat 1 and a valve disc 2. Flexible connection, the top of the valve seat 1 has a valve port sealing surface 11 matching the valve disc 2, the valve disc 2 has a valve disc sealing surface matching the valve port sealing surface 11, the rotating shaft 6 is equipped with a torsion spring 7, and the torsion spring Under the action of 7, the disc 2 has a tendency to close.

[0037] In this embodiment, the sealing surface 11 of the valve port is a conical surface, and the taper of the sealing surface of the valve disc is the same as that of the sealing surface 11 of the valve port. A seal 21 is embedded on the sealing surface of the disc.

[0038] During use, when the core barrel is lifted up to a certain height and its bottom passes over the valve disc 2, t...

Embodiment 2

[0041] The difference between this embodiment and Embodiment 1 is that in this embodiment, the sealing surface 11 of the valve port has a supporting surface for supporting the valve disc 2; when the valve disc 2 is closed, the bottom of the valve disc 2 is against the supporting surface of the valve seat 1 superior. The coefficient of friction of the bearing surface in this embodiment is 0.12-0.3.

[0042] When the valve clack 2 is closed, the present invention can impose displacement constraints on its bottom surface and side surfaces, can effectively improve the anti-deformation capability of the sealing surface, enable the valve to withstand higher pressure, and improve the pressure-holding capability of the valve. During the pressure process of the disc 2, the deformation of the middle part is larger than that of the edge, causing the edge to expand outward, forming a "virtuous circle" that becomes tighter and tighter.

[0043] Due to the special structure of the fidelity...

Embodiment 3

[0046] The difference between this embodiment and the first embodiment is that: Figure 5-8 As shown, in this embodiment, a groove 15 conformally matched with the valve flap 2 is provided on the valve port sealing surface 11 to form a supporting surface, and the bottom of the valve flap 2 has a convex portion 22 adapted to the groove 15. When the valve flap 2 is closed , the protrusion 22 is embedded in the groove 15 . The cone angle of the sealing surface 11 of the valve port is 40°-50°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com