Forming method of long-dimension diaphragm sleeve for pulse engine

A molding method and engine technology, which is applied in the field of pulse engine casing molding, can solve the problems of heavy structural weight, difficult heat insulation, small pressure-bearing and opening pressure ratio of the isolation device, etc., and achieve a reasonable transition mode, reduce negative mass, and eliminate stress concentrated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

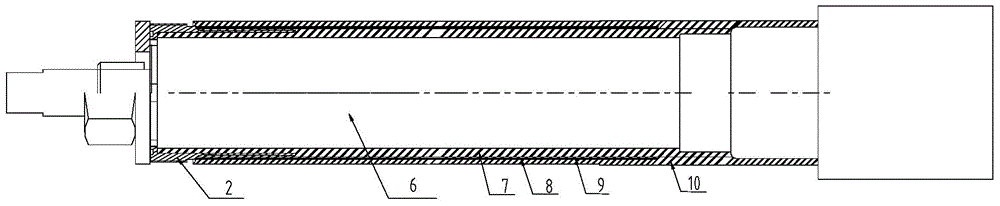

[0034] A method for forming a long-size diaphragm sleeve of a pulse engine is characterized in that it comprises the following steps:

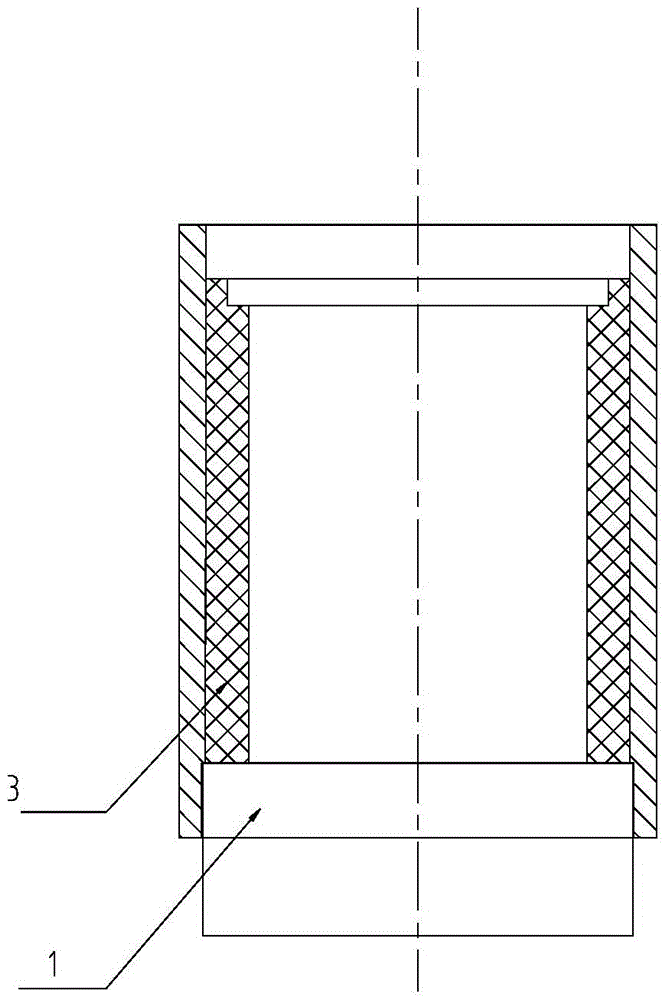

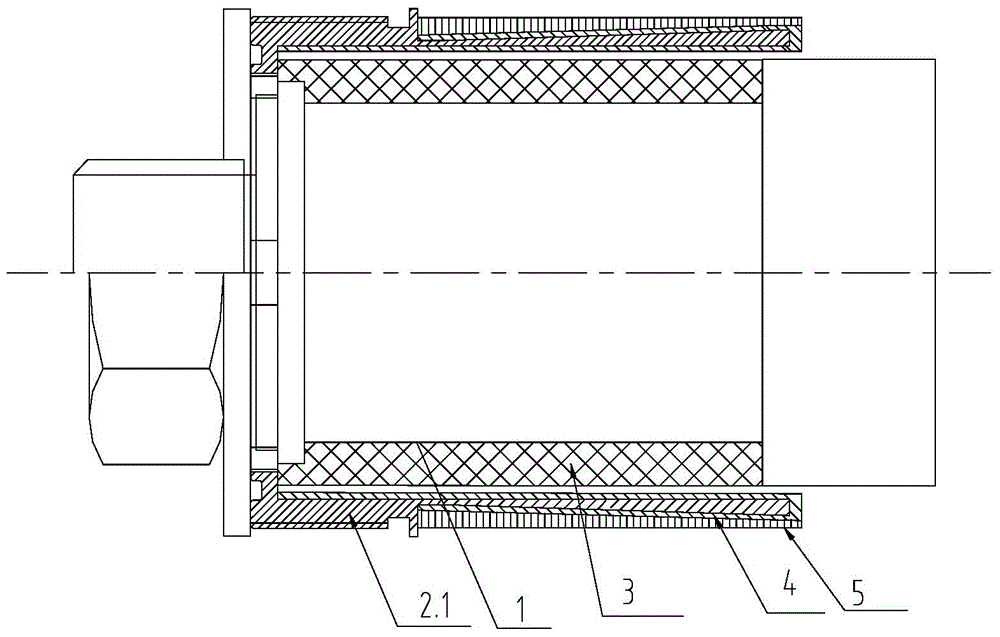

[0035] 1) Determine the thickness of the thermal insulation layer and the fiber composite layer according to the product structure characteristics and functional characteristics requirements, and prepare the casting mold 1 for sleeve molding and the metal connector 2.1;

[0036] 2) Preparation of joint 2 containing metal connection 2.1

[0037] a. Pour liquid silicone rubber into the cavity of the casting mold 1, vibrate the casting mold 1 after pouring to expel the bubbles in the cavity, and place the casting mold with silicone rubber at room temperature for 24 hours to vulcanize the silicone rubber ; After vulcanization, a silicone rubber mold 3 is obtained;

[0038] b. Sand-blowing the bonding surface of the inner wall of the metal connector 2.1 bonded to the nitrile rubber 4, so that the inner bonding surface of the metal connector 2.1 is uniforml...

Embodiment 2

[0047] A method for forming a long-size diaphragm sleeve of a pulse engine is characterized in that it comprises the following steps:

[0048] 1) Determine the thickness of the thermal insulation layer and the fiber composite layer according to the product structure characteristics and functional characteristics requirements, and prepare the casting mold 1 for sleeve molding and the metal connector 2.1;

[0049] 2) Preparation of joint 2 containing metal connector 2.1

[0050] a. Pour liquid silicone rubber into the cavity of the casting mold 1, vibrate the casting mold 1 after pouring, so as to expel the bubbles in the cavity, and place the casting mold with silicone rubber at room temperature for 48 hours to vulcanize the silicone rubber ; After vulcanization, a silicone rubber mold 3 is obtained;

[0051] b. Sand-blowing the bonding surface of the inner wall of the metal connector 2.1 bonded to the nitrile rubber 4, so that the inner bonding surface of the metal connector 2.1 is un...

Embodiment 3

[0060] A method for forming a long-size diaphragm sleeve of a pulse engine is characterized in that it comprises the following steps:

[0061] 1) Determine the thickness of the thermal insulation layer and the fiber composite layer according to the product structure characteristics and functional characteristics requirements, and prepare the casting mold 1 for sleeve molding and the metal connector 2.1;

[0062] 2) Preparation of joint 2 containing metal connector 2.1

[0063] a. Pour liquid silicone rubber into the cavity of the casting mold 1, vibrate the casting mold 1 after pouring to expel the bubbles in the cavity, and place the casting mold with silicone rubber at room temperature for 36 hours to vulcanize the silicone rubber ; After vulcanization, a silicone rubber mold 3 is obtained;

[0064] b. Sand-blowing the bonding surface of the inner wall of the metal connector 2.1 bonded with EPDM 4 to make the surface of the inner bonding surface of the metal connector 2.1 uniformly ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com