Gravure printing device

A technology of gravure printing and scraper device, which is applied in the direction of gravure rotary printing machine, printing, printing machine, etc., can solve the problems of high manufacturing cost and complex structure of gravure printing equipment, reduce equipment cost, eliminate vibration phenomenon, and improve working speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

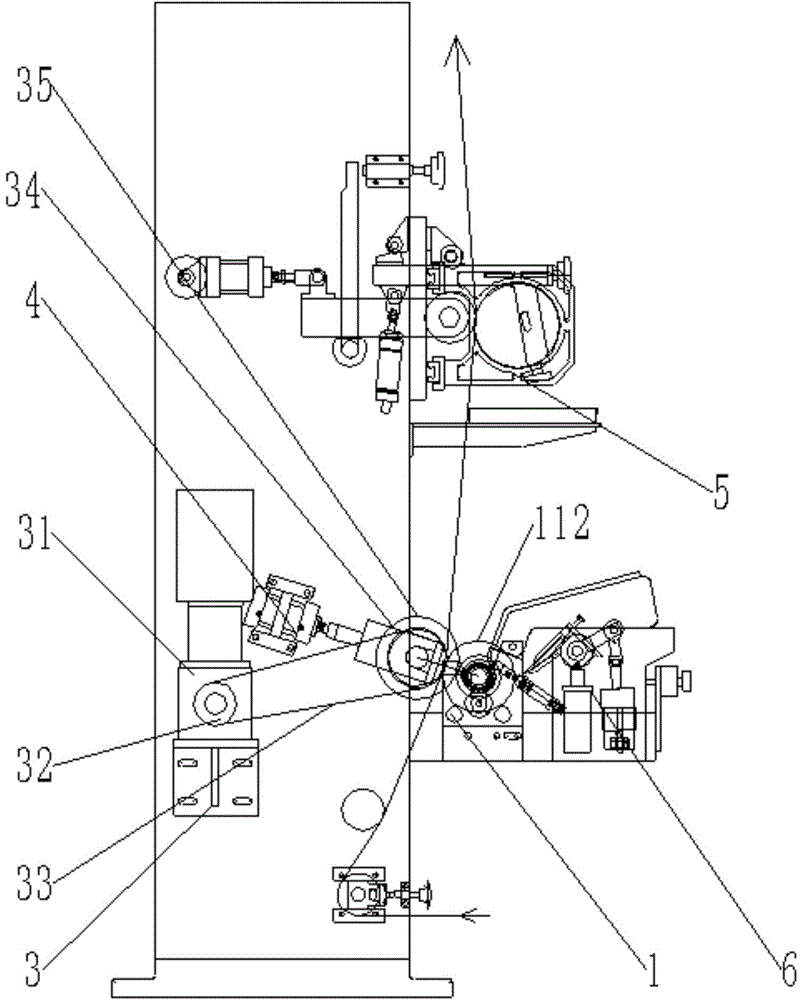

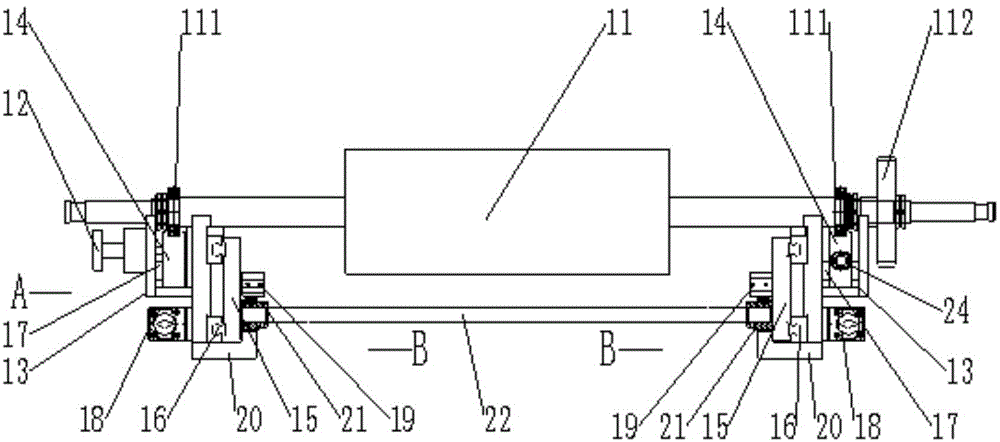

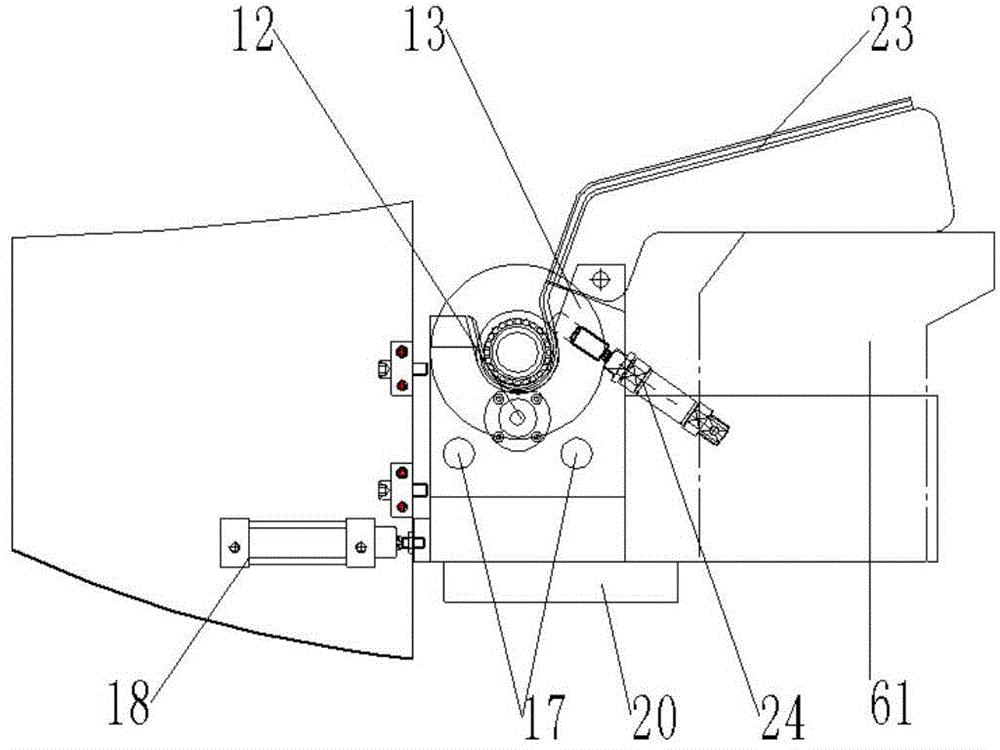

[0027] combined with figure 1 -9, describe in detail the technical solutions, structural components and features proposed by the present invention.

[0028] As the printing speed is getting higher and higher, the shaftless plate loading and scraper device currently used in the gravure device has a complex structure and lower reliability, especially when the shaftless plate loading scraper device uses three supporting shafts, the support gap is not easy to control , In the case of high-speed work, due to the flutter of the scraper, the scraping ink is not clean, which seriously affects the use of the gravure device. For this reason, the present invention proposes a novel gravure printing device that can effectively overcome the above-mentioned shortcomings, has a simple structure, is easy to use, and can be applied to gravure printing machine...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap