Double continuously variable transmission steering mechanism

A technology of steering mechanism and belt-type stepless speed change, which is applied in the direction of steering mechanism, non-deflectable wheel steering, mechanical equipment, etc., and can solve the problems of safety accidents that are easy to roll over, difficult to apply to tracked vehicles, and difficult to turn to tracked vehicles. , to achieve high safety, ensure steering flexibility, and improve the safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

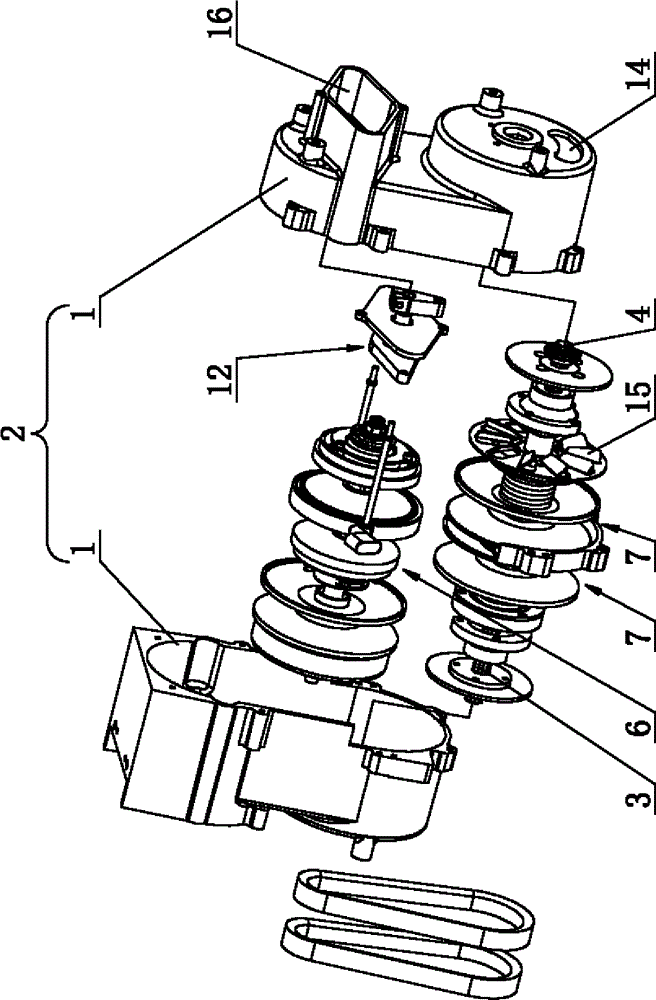

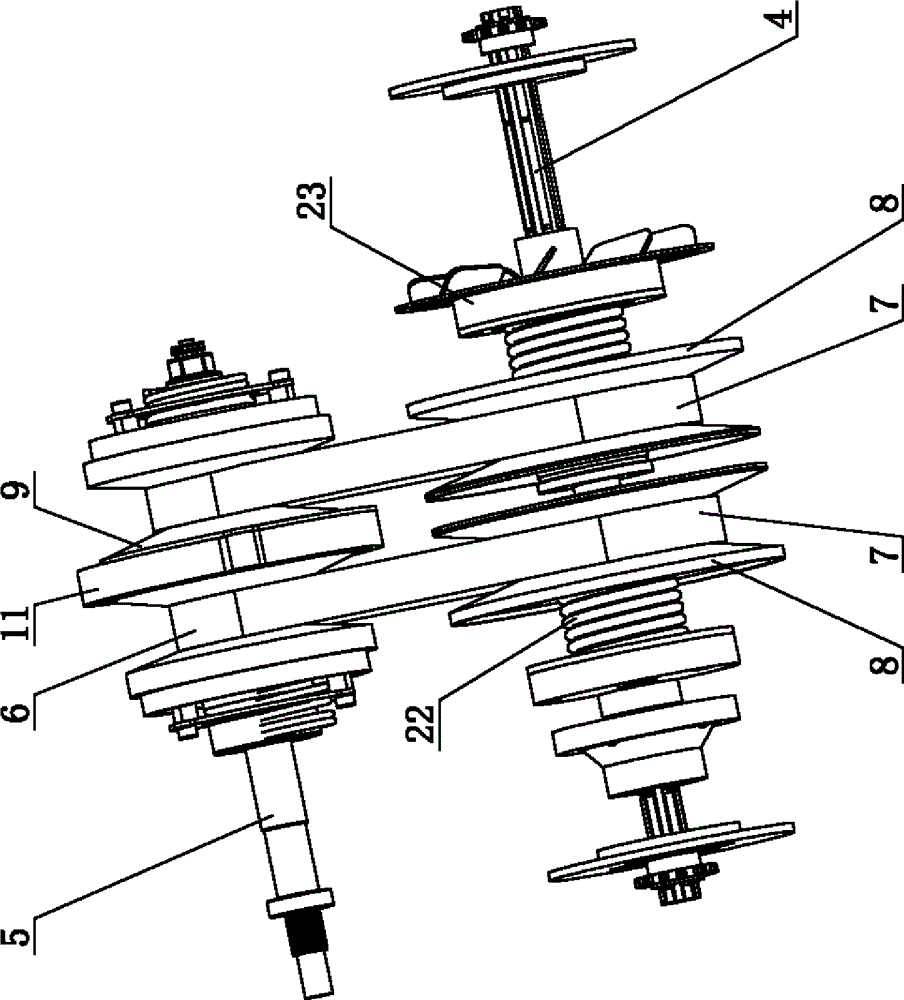

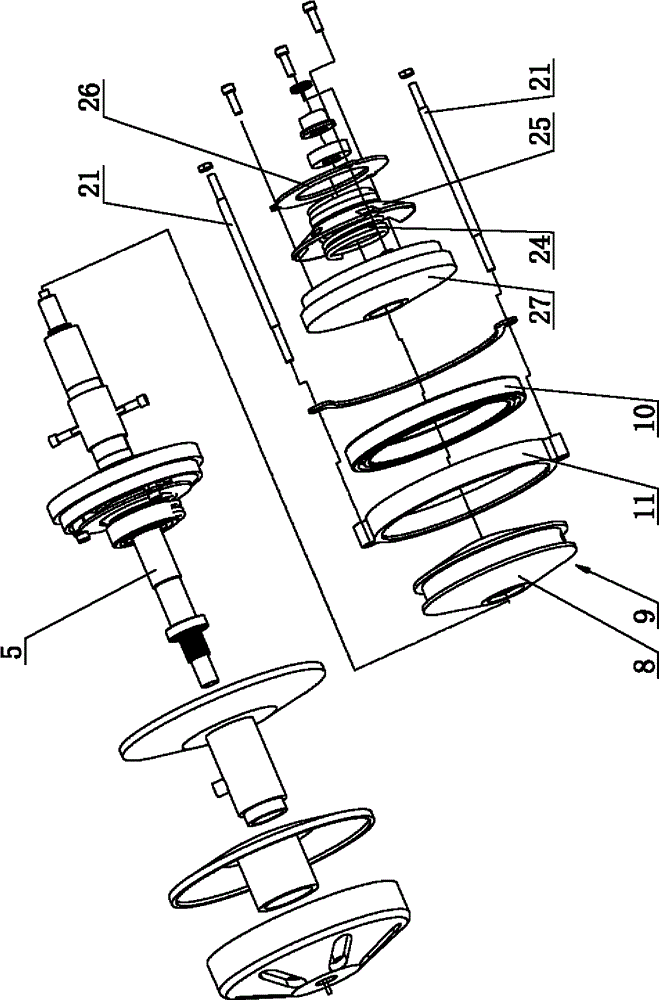

[0019] Such as Figure 1 to Figure 4 As shown, a double stepless speed change steering mechanism includes a reduction box body 2, a left output shaft 3 installed in the reduction box body 2, a right output shaft 4 and a main drive shaft 5, and the reduction box body 2 is composed of two shells The body 1 is combined to form, and the main transmission shaft 5 is respectively connected to the left output shaft 3 and the right output shaft 4 through two belt-type continuously variable transmission mechanisms. The belt-type continuously variable transmission mechanism includes two driving pulleys 6 installed on the main transmission shaft 5 and two driven pulleys 7 respectively installed on the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com