Film roll paying-off device

A film roll and telescopic device technology, which is applied in the direction of winding strips, transportation and packaging, thin material handling, etc., can solve the problems of time required for lifting trolleys, waste of manpower, and workers injured by film rolls, so as to reduce the number of people. The effect of investment, saving manpower and reducing the chance of slipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

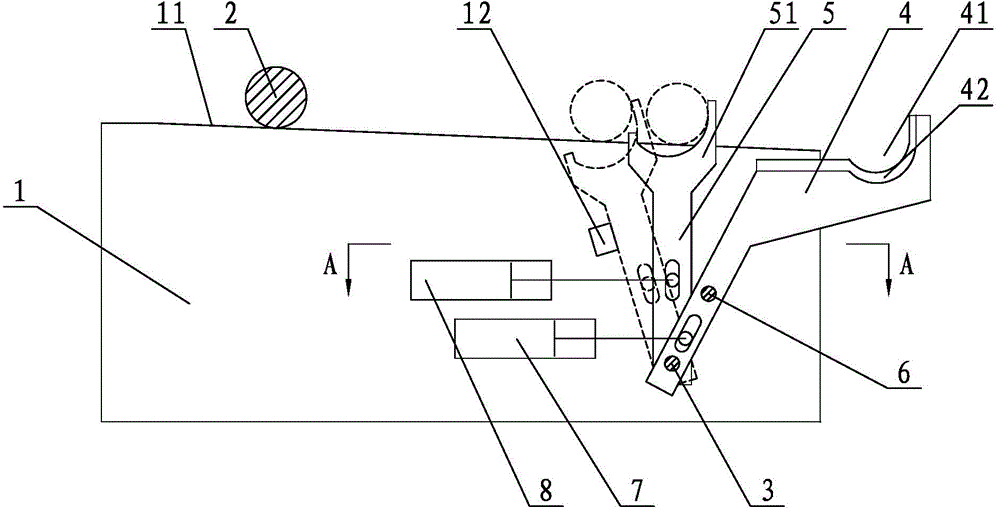

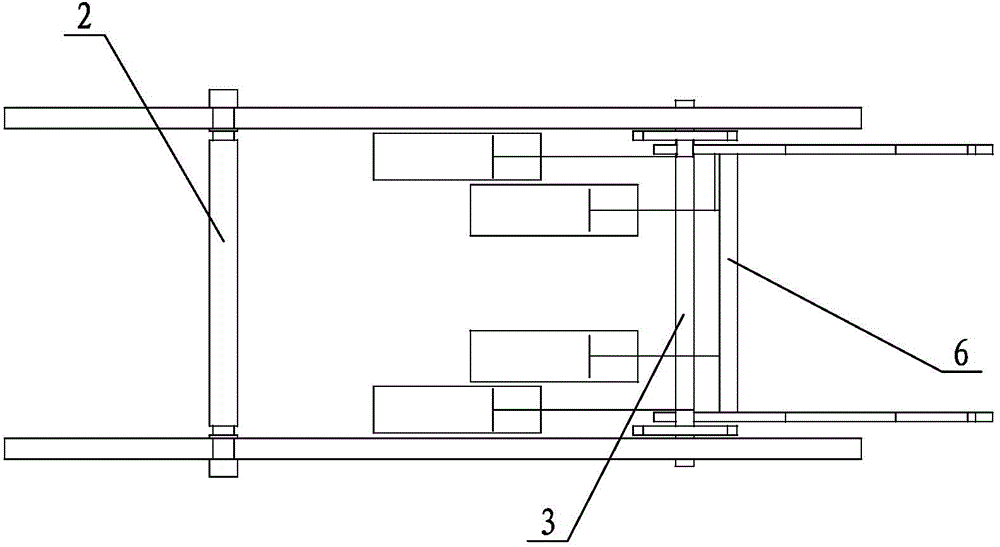

[0017] Such as Figure 1-Figure 2 A kind of film unloading device shown, comprises support frame 1 that supports film roll 2 two ends and the film roll conveying part that is arranged in support frame 1, and support frame 1 is provided with two mutuals that guide film roll roll 2 to roll. Parallel to the guide rail 11, the film on the film blowing unit is wound on the film roll 2 to be wound up. After the winding is completed, the film roll 2 is guided to the conveying part through the guide rail 11. The transmission part includes a mandrel 3 arranged at the bottom of the support frame 1, two rotating arms 4 and two driving rods 5 respectively rotatably connected to both ends of the mandrel 3, and a cross bar 6 fixedly connected to the rotating arms 4 at both ends. 1. Drive the first telescopic device 7 and the second telescopic device 8 that rotate the two pivoting arms 4 and the two driving rods 5 around the mandrel 3 respectively. The shift fork 51 on the edge, the free en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com