Tie-back barrel device capable of rotating into well

A tie-back sleeve and slide sleeve technology, applied in wellbore/well components, earthwork drilling and production, etc., can solve the problems of prolonging the construction period, consuming manpower and material resources, increasing well control risks, etc., so as to increase reliability and guarantee smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

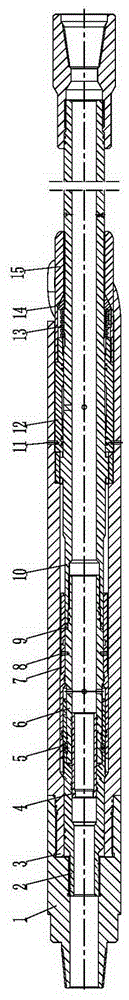

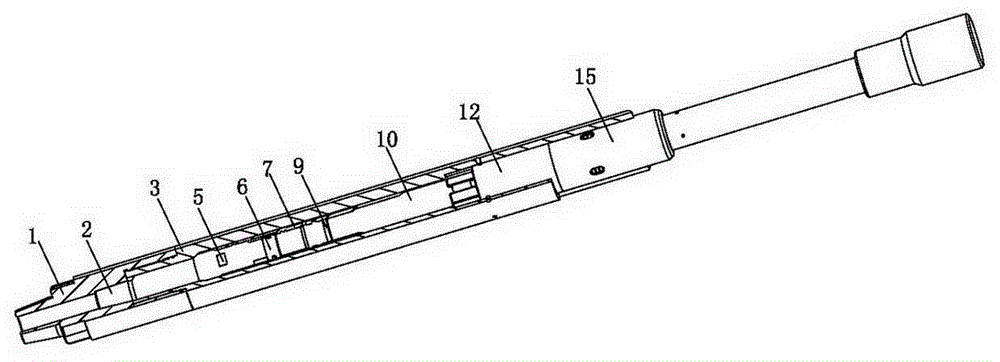

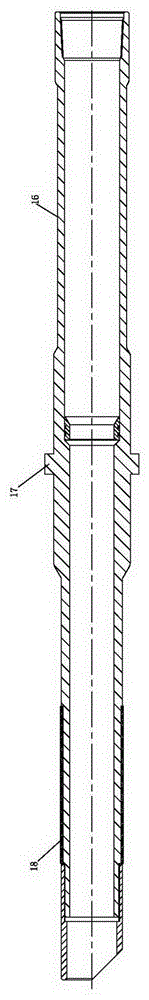

[0008] A device that can be transferred into the well return connection, such as Figure 1-7 As shown, it includes three major parts, which are respectively: torque transmission unit, double throwing unit and return unit. 14. The retaining cylinder 15 is composed of the connecting cylinder 3. Four key grooves and four protruding keys are evenly arranged on the sliding cylinder 12. In the working state, the key grooves of the sliding cylinder 12 and the protruding keys of the upper lifting cylinder 10 Cooperate, the protruding key is matched with the keyway in the connecting cylinder 3; the sliding cylinder 12 transmits the torque of the lifting cylinder 10 to the connecting cylinder 3 through these two sets of matching keys; between the sliding cylinder 12 and the lifting cylinder 10 There is an inner cavity with a poor area, and four pressure transmission holes are set on the upper lifting cylinder 10, which can transmit the pressure to the inner cavity; Corresponding thread...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com