Two-dimensional physical simulation testing system for deeply-buried tunnel water bursting hazard and testing method thereof

A physical simulation and test system technology, which is applied in the field of test systems for simulating water inrush disasters in deep buried tunnels and tunnel surrounding rock failure and instability, can solve the problem of difficult physical simulation of water inrush disasters in deep buried karst tunnels, inability to change the location of water sources, Problems such as deep high ground stress and water pressure cannot be realized, and the effect of good water sealing and accurate monitoring results can be achieved

Active Publication Date: 2015-04-22

CHINA UNIV OF MINING & TECH

View PDF10 Cites 41 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the test system is designed for the Qingdao Jiaozhou Bay Submarine Tunnel. It has its natural defects in the tunnel water inrush test research. For example, the location of the water source cannot be c

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

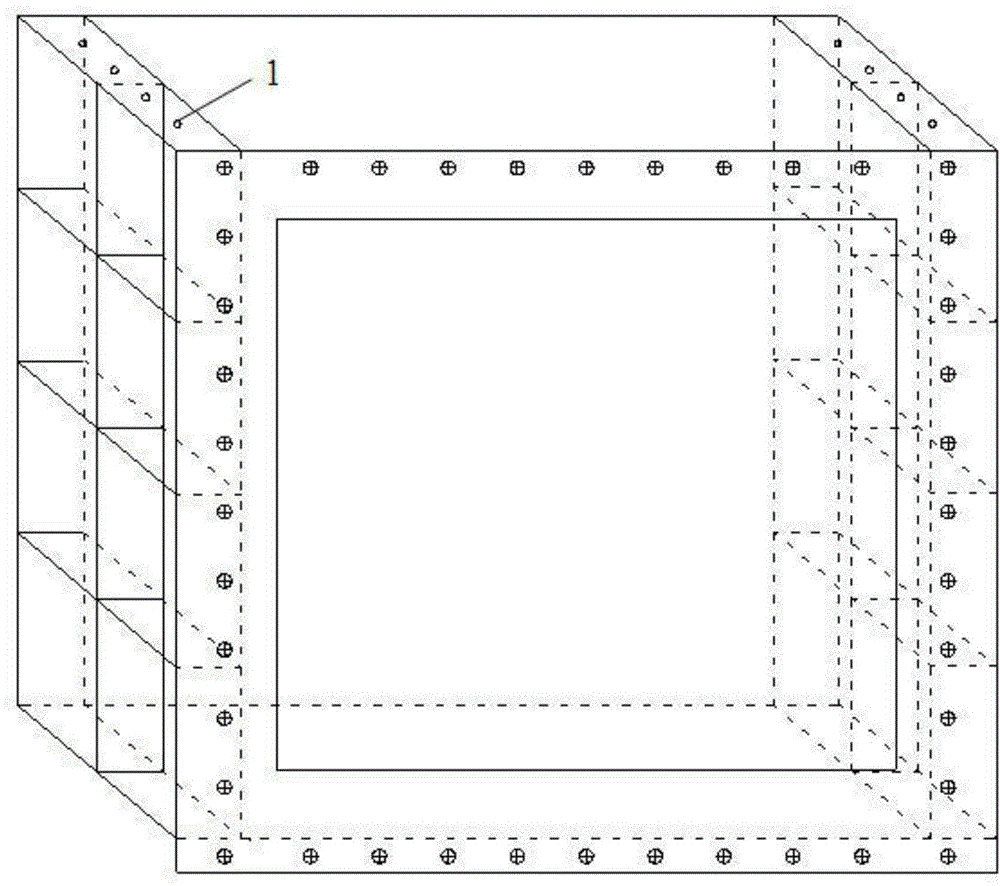

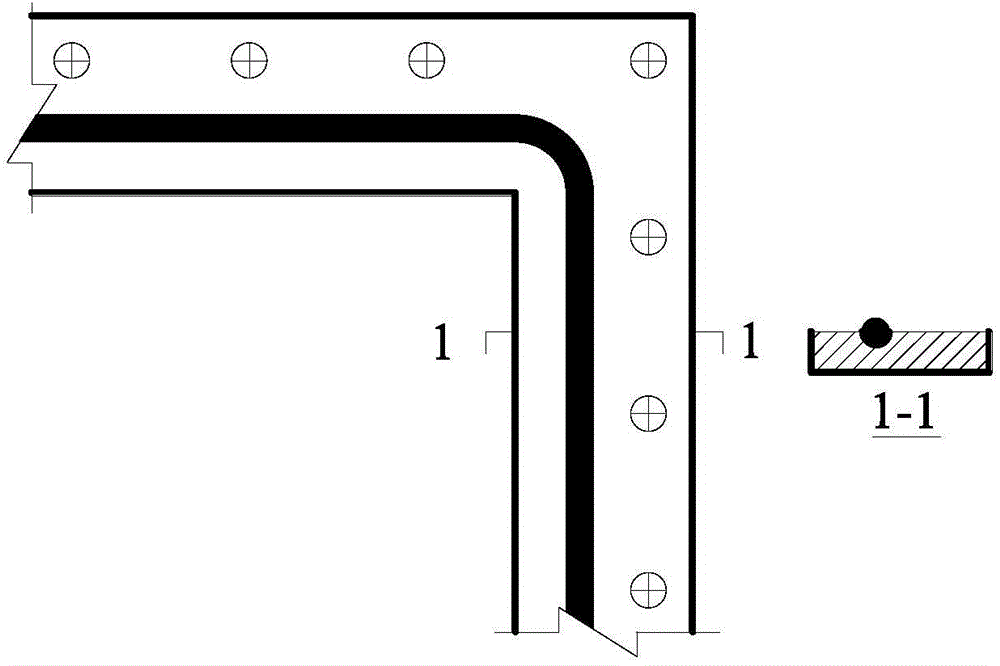

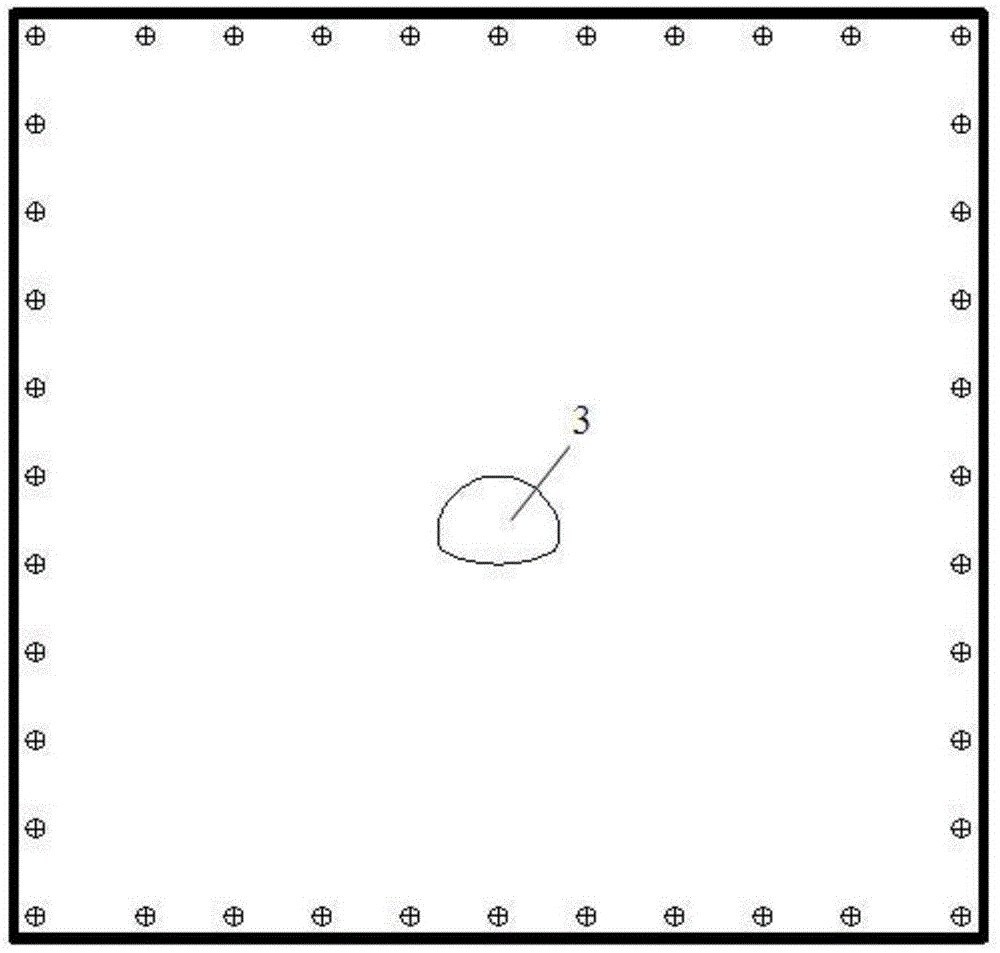

The invention discloses a two-dimensional physical simulation testing system for deeply-buried tunnel water bursting hazard. The two-dimensional physical simulation testing system comprises a rigid testing box, a water pressure servo control system, a vertical loading system, pressure stress sensors and seepage pressure sensors. The rigid testing box is of the cubic structure with an opening arranged on the top. The frontal side surface of the rigid testing box is a high intensity glass plate. The high intensity glass plate is provided with a reserved tunnel portal. Rock-like materials are paved inside the rigid testing box, and a karst cave hollow cavity is arranged in a predetermined position. The pressure stress sensors and the seepage pressure sensors are arranged around the karst cave hollow cavity and a tunnel. The karst cave hollow cavity is communicated with the water pressure servo control system through a high pressure water pipe. A setting load value is loaded by the opening on the top of the rigid testing box through the vertical loading system. The two-dimensional physical simulation testing system has the advantages that the structure is simple, the rigidness is strong and water-sealing capability is good. The two-dimensional model testing system and the method of the two-dimensional model testing system enable a more direct observation on surrounding rock rupture evolvement characteristics during the tunnel water bursting process.

Description

Technical field [0001] The invention relates to the technical field of tunnel engineering, in particular to a test system for simulating the water inrush disaster of a deep buried tunnel and the failure and instability of the surrounding rock of the tunnel. Background technique [0002] The catastrophic evolution mechanism of water inrush disasters in deep-buried tunnels is one of the hotspots and difficulties in the scientific research of the National Key Basic Research and Development Plan (973). At present, the buried depth of tunnels in the field of transportation and water conservancy engineering in my country has increased significantly, and the buried depth of kilometers is constantly emerging. The buried depth of the diversion tunnel of Jinping II Hydropower Station even reaches 2525m. The disasters caused by this during the construction period are becoming more and more serious. Among them, water inrush is The major geological disasters that are common in the tunneling pr...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N33/00

Inventor 靖洪文苏海健蔚立元朱谭谭朱文心

Owner CHINA UNIV OF MINING & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com