Frame-type postposed reversing ditcher

A ditching machine and frame-type technology, which is applied in the field of frame-type post-reverse reverse ditching machines, can solve the problems of high labor intensity, poor ditching quality, and laborious crossing of field ridges, etc., and achieve good ditching quality and improved Efficacy and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

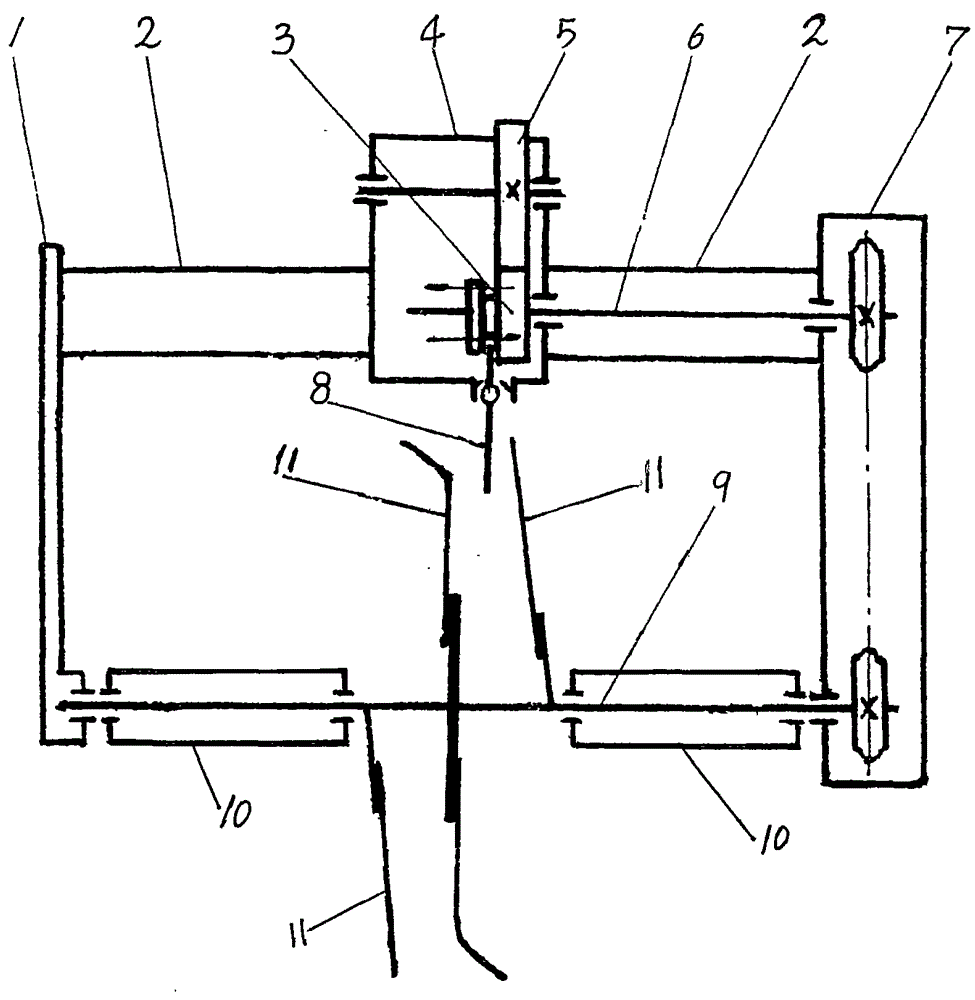

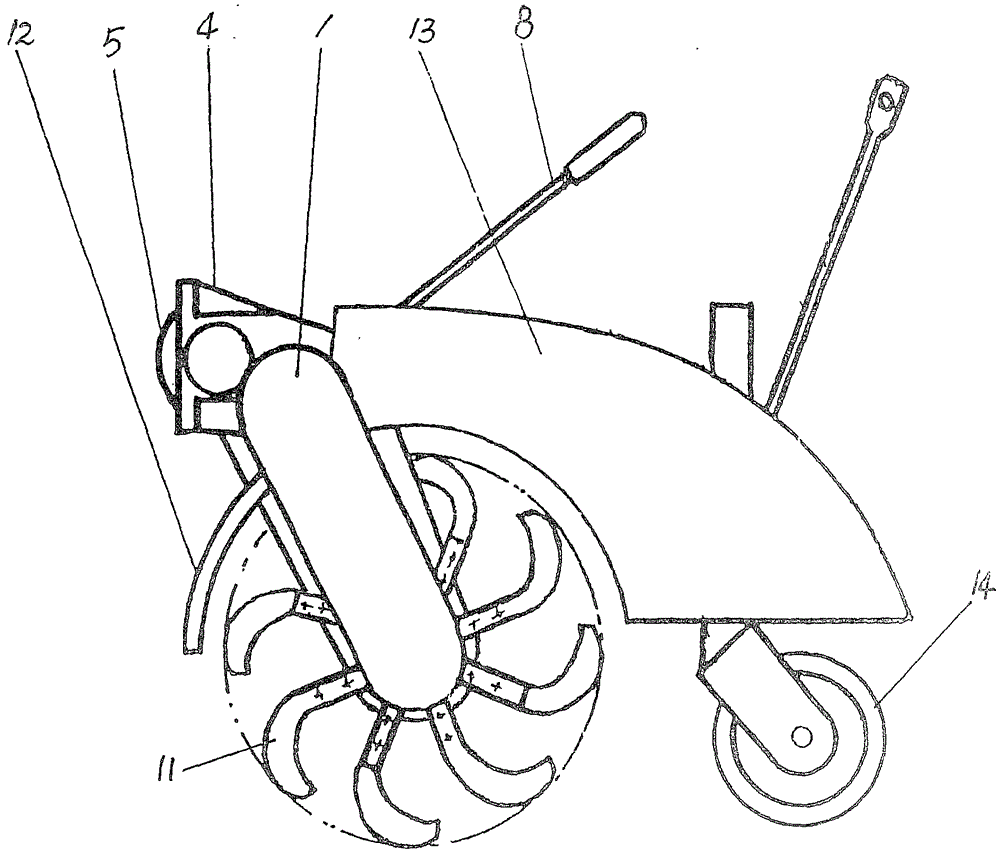

[0010] Such as figure 1 , figure 2 The shown frame-type rear reverse ditching machine includes a transmission gearbox 4 fixed on the left and right casings 2, a side transmission box 7 and a support arm 1, and the side transmission box 7 and the lower part of the support arm 1 Supporting both ends of the cutter shaft 9, the cutter shaft 9 outside the ditching cutter 11 is set on the cutter shaft 9 with a sleeve 10 through a bearing and a dust-proof ring. During operation, the cutter shaft 9 and the ditching cutter 11 rotate, and the sleeve 10. There is soil sticking on the surface and rolling on the ground by itself. It does not rotate with the cutter shaft 9. The casing 10 does not rotate and will not wind the straw. The transmission gear 3 installed on the transmission shaft 6 has 19-24 teeth. Install a bridge gear 5 in front of 3, and the bridge gear 5 meshes with the I reverse gear 17-tooth gear in the chassis of the hand drag. By adding a bridge gear 5, the cutter shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com