Paint spraying machine for production and processing of computer host case

A technology of computer mainframe and paint spraying machine, applied in the direction of spraying device, etc., can solve the problems of workers' health hazards, inconvenient ceiling spraying, slow speed of manual spraying, etc., and achieve the effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

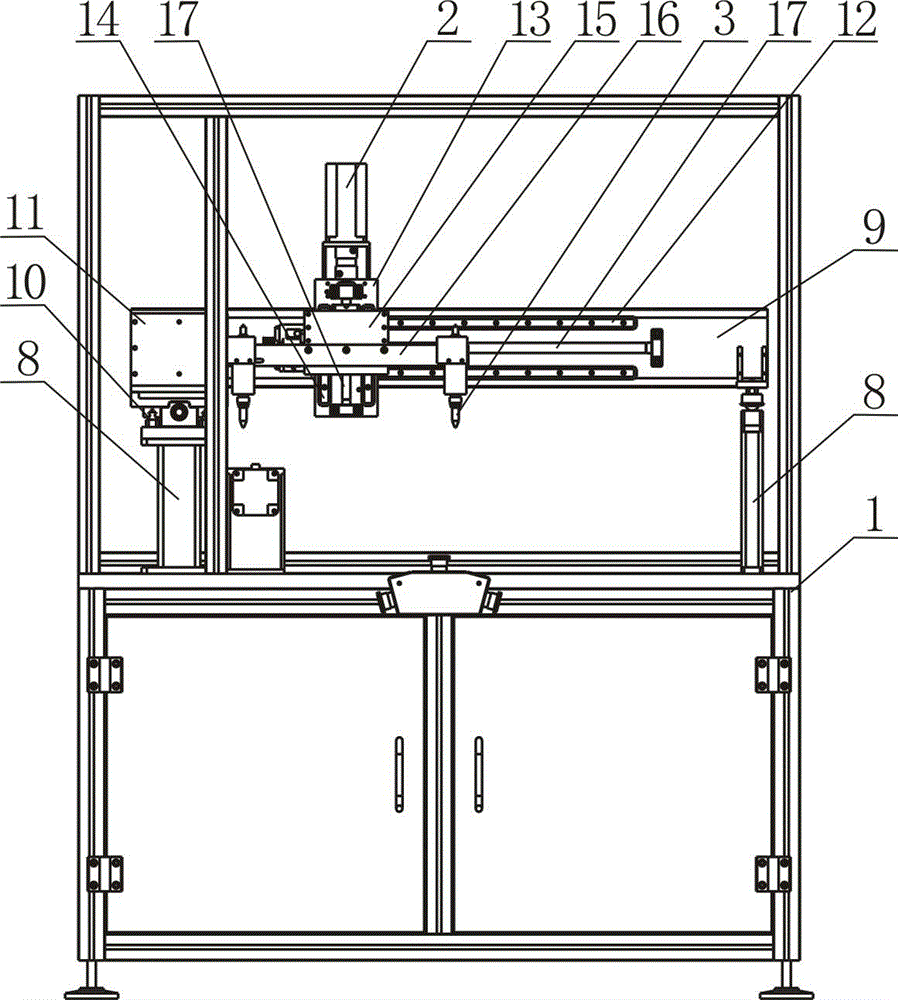

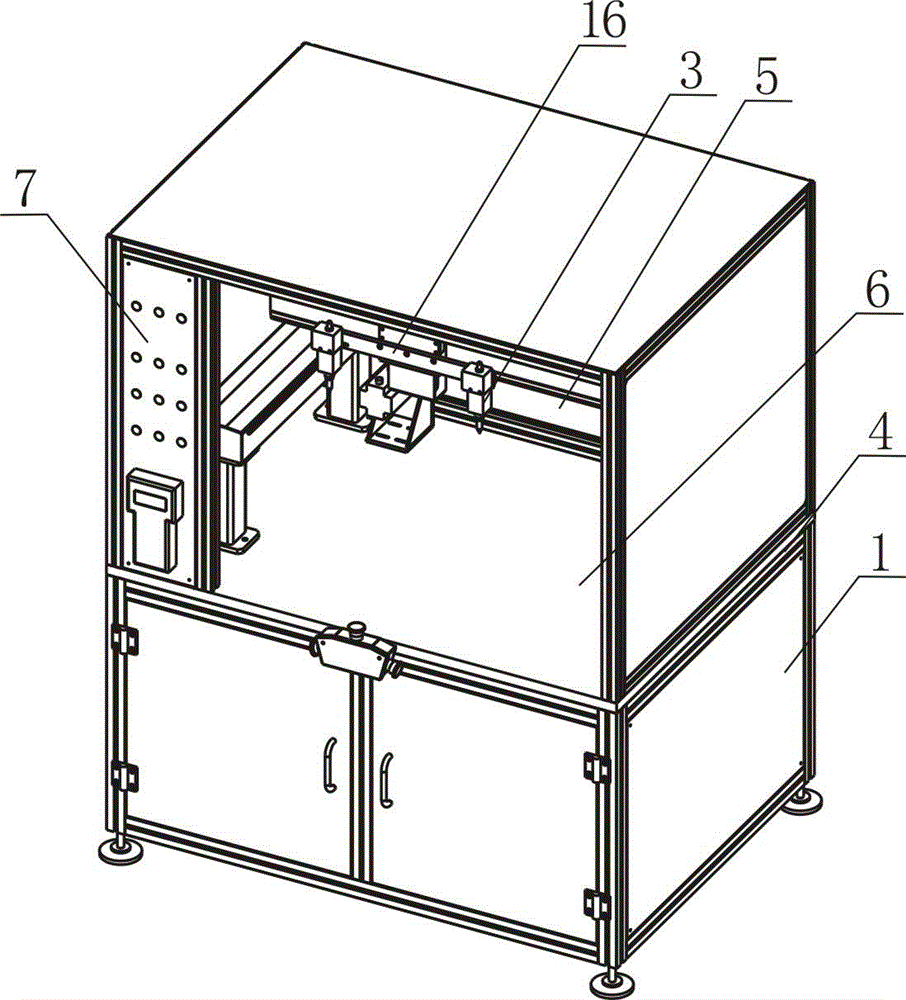

[0014] Such as figure 1 , 2 As shown, the paint spraying machine for the production and processing of computer mainframes includes a paint spraying station 1, three motors 2 and two paint spraying guns 3. 4. The bracket 5 is set on the horizontal partition 4, and the box body and the front and rear side walls opposite to the bracket 5 are respectively provided with openings 6 to form a conveying channel for the workpiece to be coated. A controller 7 is arranged on the side of the opening 6 on the box body, and the support 5 is composed of two bases 8 and a horizontal bar 9, wherein one base 8 is provided with a longitudinal guide rail 10, and one end of the horizontal bar 9 is provided with a Vertically moving slide block 11, described vertically moving slide block 11 is arranged on the longitudinal guide rail 10, and the other end is supported on another base 8; Slider 13; vertical rail 14 is provided on the horizontal slider 13, vertical rail 14 is provided with vertical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com