Damping air hammer

A technology of air hammer and hammer head, which is applied in the field of forging to achieve the effect of reasonable design and labor saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

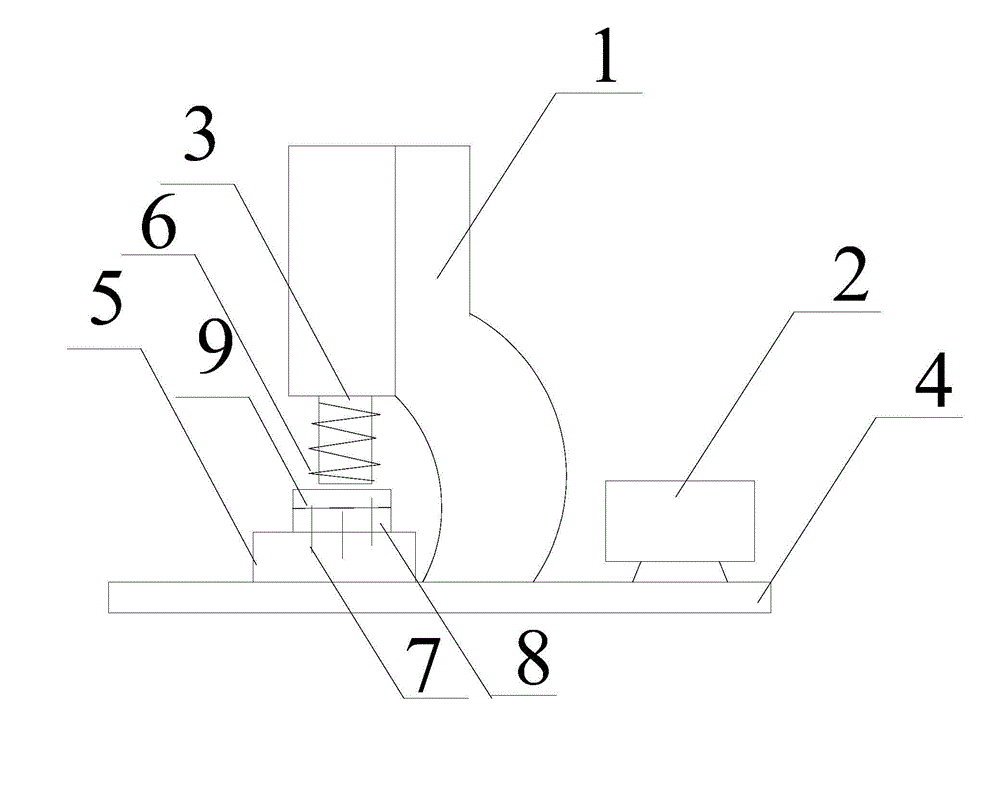

[0013] A kind of shock-absorbing air hammer of the present embodiment comprises a fuselage 1, a motor 2, a hammer head 3, an anvil 5 and a base 4, a spring sleeve 10 is arranged on the outside of the hammer head 3, and an anvil 5 below the hammer head 3 On the top, a firmware table 8 is provided, and a number of jacks are arranged inside the firmware table 8, and a firmware mold 9 arranged on the firmware table 8 is also matched with the shock-absorbing air hammer, and the bottom of the firmware mold 9 is provided with a The pillar corresponding to the internal jack of platform 8. Be convenient to change firmware mold 9 like this, only need to propose firmware mold 9 and get final product.

[0014] The firmware table 8 is welded on the anvil 5, and a number of reinforcing ribs 7 are arranged around it, so as to enhance the anti-beating ability.

[0015] Firmware die 9 is circular or rectangular, depending on the shape of common forgings, raised around, smooth in the middle, j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com