Copper material rack

A technology for supporting rods and cross rods, applied in tool storage devices, manufacturing tools, etc., can solve the problems of acid stains, affecting product quality, and inability to remove acid water in the pipe, and achieve the effect of safe placement and maintaining surface properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

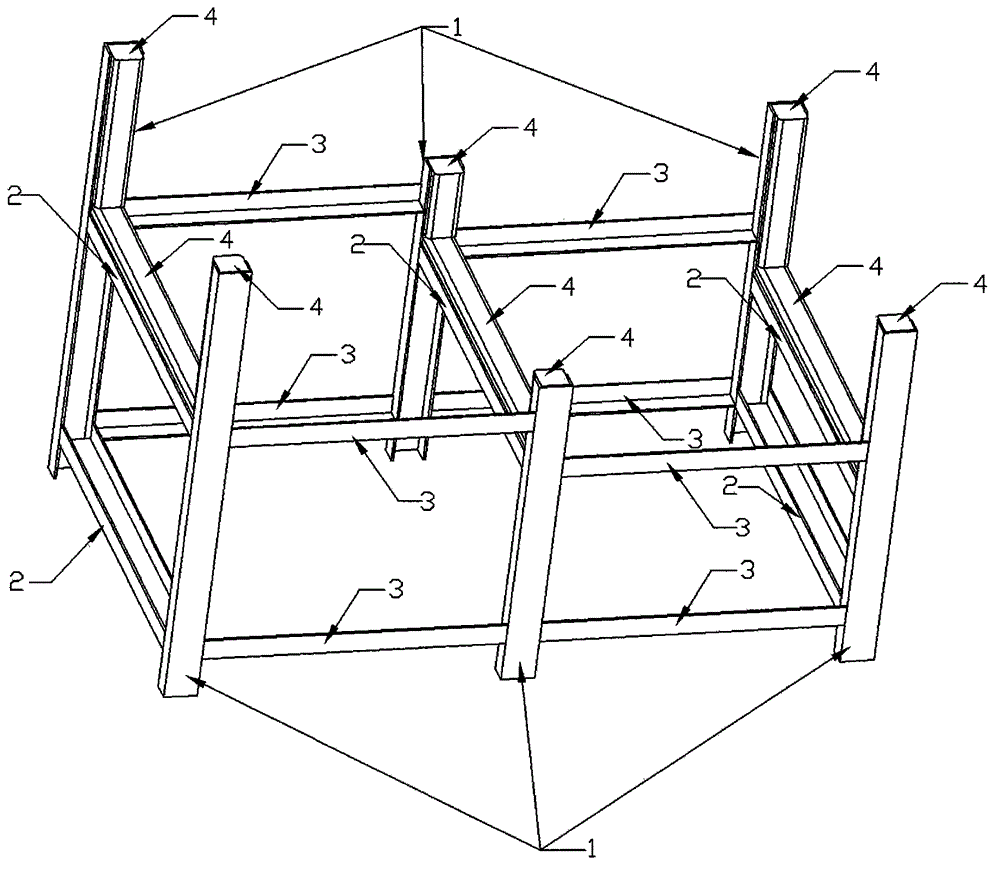

[0009] The copper material frame of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0010] figure 1 The copper material frame shown is composed of a support bar 1, a cross bar 2 and a connecting bar 3, and the cross bar 2 is used to connect between the lower part of the first set of two support bars 1 and the middle upper part respectively, and the A group of two supporting rods 1 arranged in parallel are connected by connecting rods 3 between the opposite lower parts and middle parts of the second group of two supporting rods 1, and the second group of two supporting rods 1 are connected between the lower parts and the middle parts. between the two support rods 1 parallel to the second group of two support rods 1 is connected with the connecting rod 3 between the lower part and the middle part of the third group of two support rods 1 parallel to the second group of two support rods 1, and the third group of two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com