Self-locking injection nozzle device and locking control method thereof

An injection molding nozzle, self-locking technology, which is applied in the field of self-locking injection molding nozzle device and its locking control, can solve the problems of high manufacturing cost, troublesome processing, complicated control method, etc., to prevent the melt from drooling and to facilitate production , The effect of simple control method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

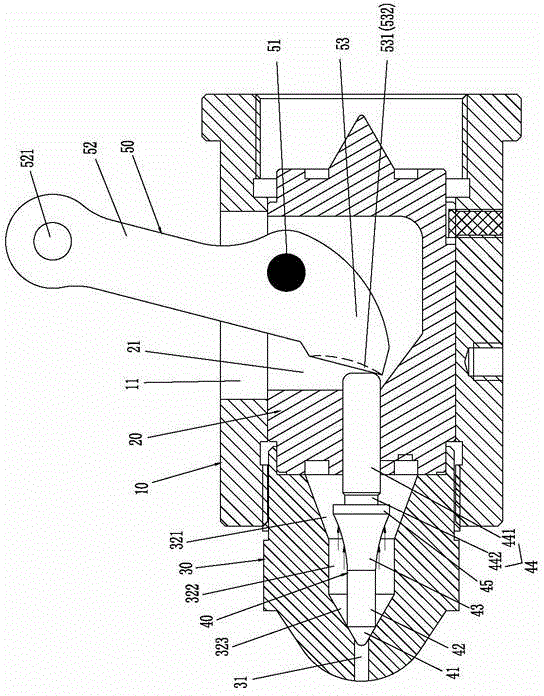

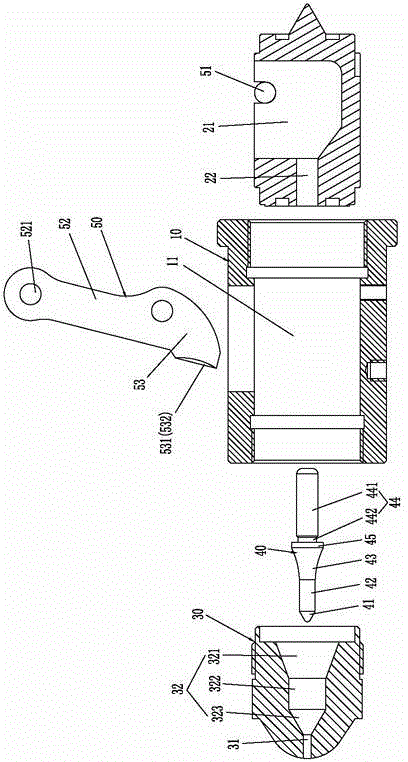

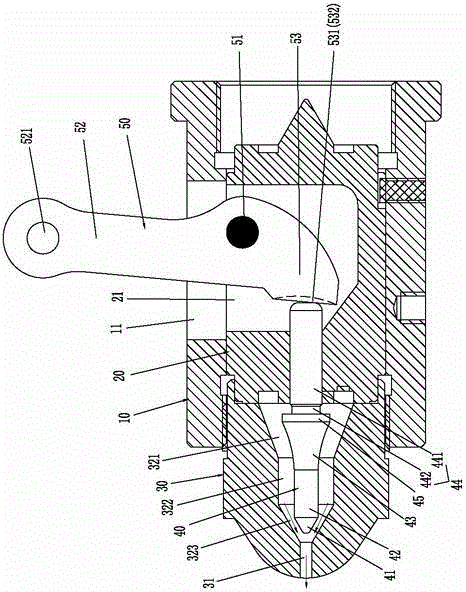

[0044] Please refer to Figure 1 to Figure 3 As shown, it shows the specific structure of the embodiment of the present invention. The self-locking injection molding nozzle device includes a nozzle cover 10, a glue valve 20, a nozzle 30, a thimble 40 and a thimble driving lever 50.

[0045] Wherein, the nozzle casing 10 has a first hollow cavity 11 inside, and the first hollow cavity 11 is respectively formed with openings at the top, front and rear ends of the nozzle casing 10 .

[0046] The glue passing valve 20 has a second hollow cavity 21, the second hollow cavity 21 is formed with an opening at the top of the glue passing valve 20, and the front end of the second hollow cavity 21 is provided with a straight channel 22 through the second hollow cavity 21 and the front end of the glue passing valve 20; in this embodiment, the inner bottom of the second hollow cavity 21 is lower than the rear end opening of the straight channel 22, and the rear end opening and the inner bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com