Buffer-type hot melting column

A hot-melt column and hot-melt technology, which is applied in the field of hot-melt tools, can solve the problems of stroke limitation, loose nut and plastic parts, easy loosening of nuts, etc., so as to facilitate debugging and prevent hot-melt pressure injury.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

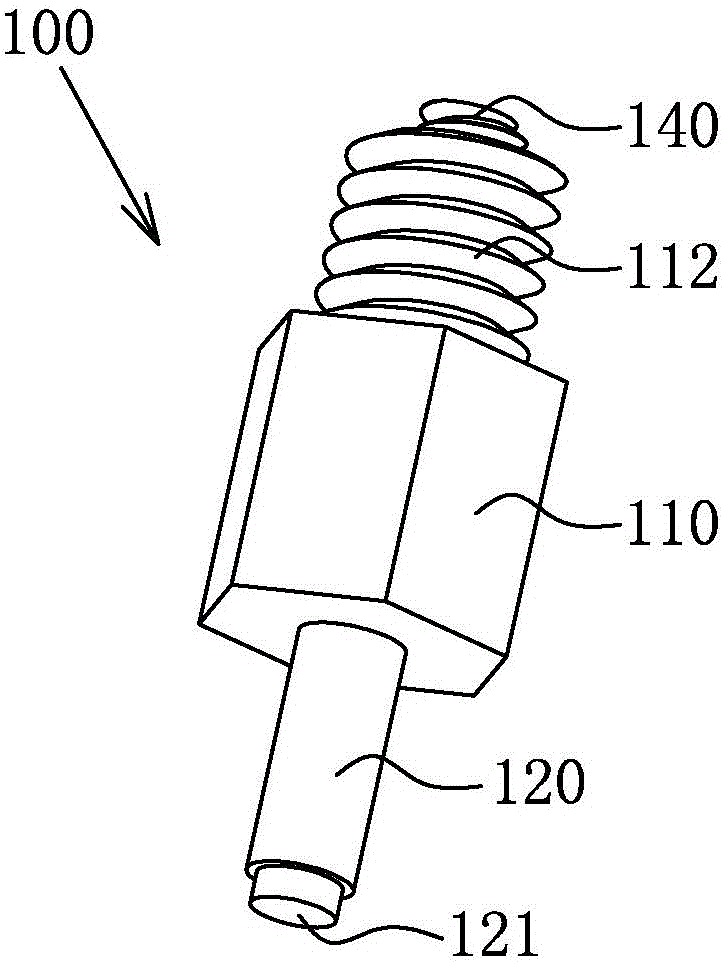

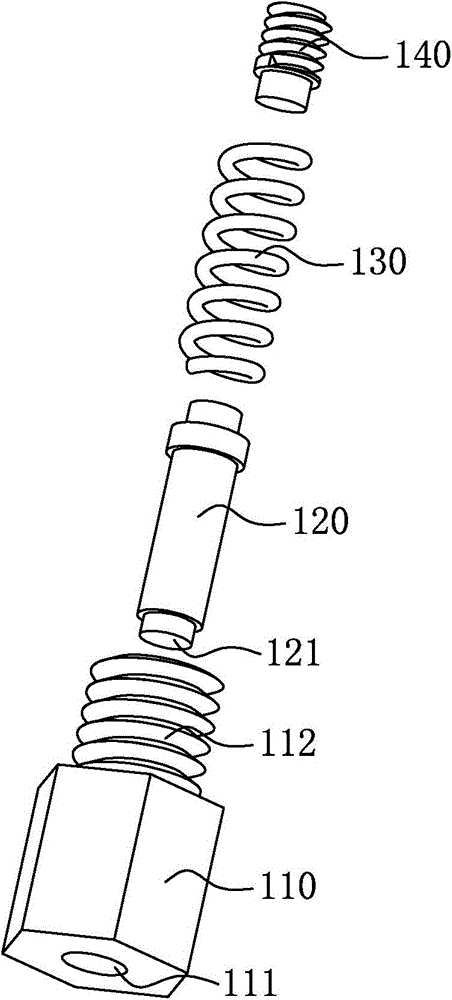

[0020] see figure 2 , image 3 and Figure 4 As shown, it respectively depicts a combined schematic diagram of a preferred embodiment of the buffer type thermal melt column of the present invention, an exploded schematic diagram of a preferred embodiment of the buffer type thermal melt column of the present invention and a preferred embodiment of the buffer type thermal melt column of the present invention A schematic diagram of an embodiment in a working state.

[0021] In a preferred embodiment, the buffered heat-melt column 100 of the present invention is used to thermally implant the nut 200 into the plastic part 300. The buffered heat-melt column 100 includes:

[0022] Connecting body 110, which is a columnar body, the connecting body 110 is provided with a through hole 111, and one end of the connecting body 110 is provided with an external thread 112;

[0023] One end of the hot melt element 120 is clamped in the through hole 111, and the other end extends from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com