A multi-axis combined label handling device

A handling device and combined technology, applied in the directions of labeling, transportation and packaging, packaging, etc., can solve the problems of labeling failure, large errors, and labels that cannot be affixed, and achieve the effect of improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

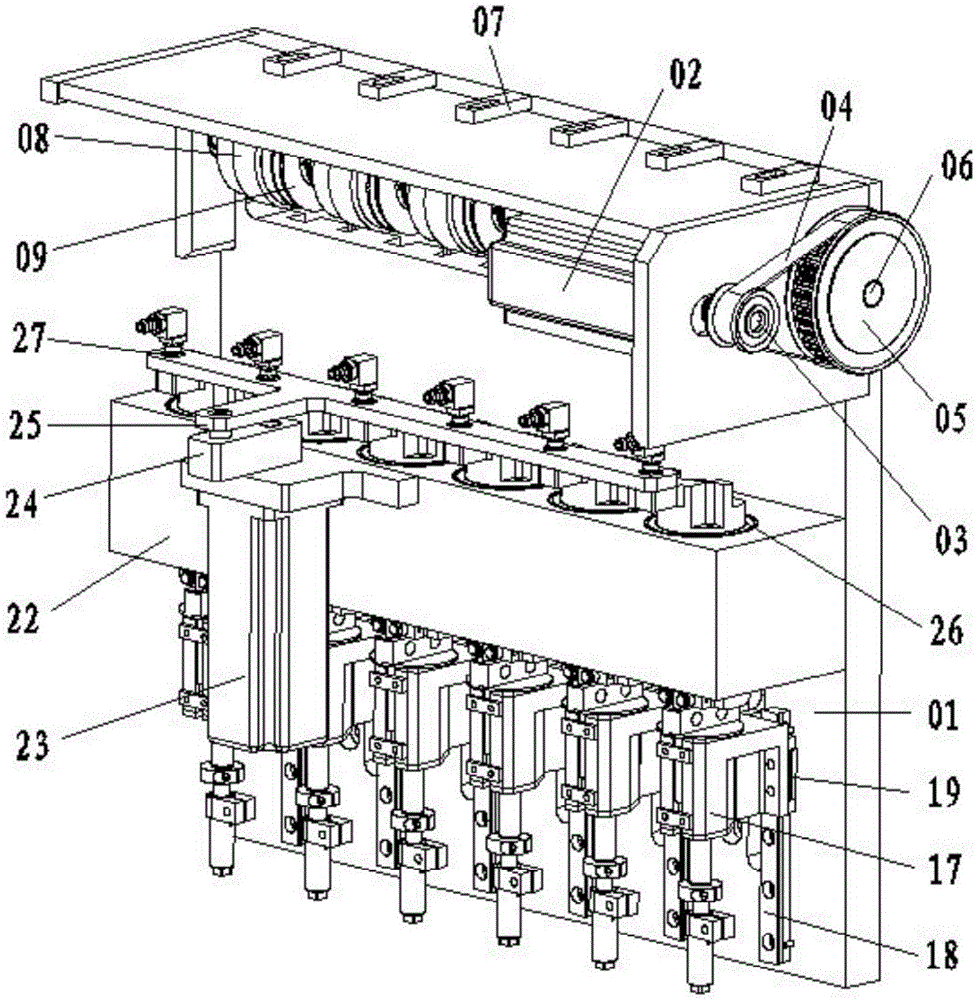

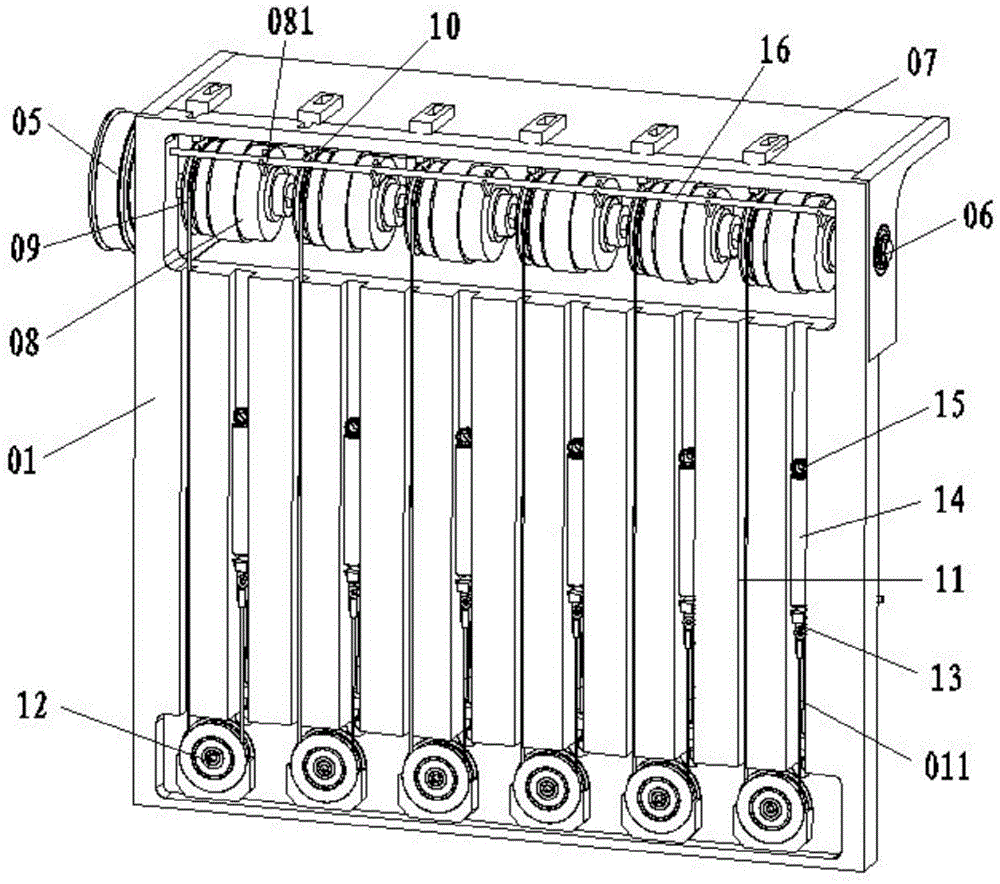

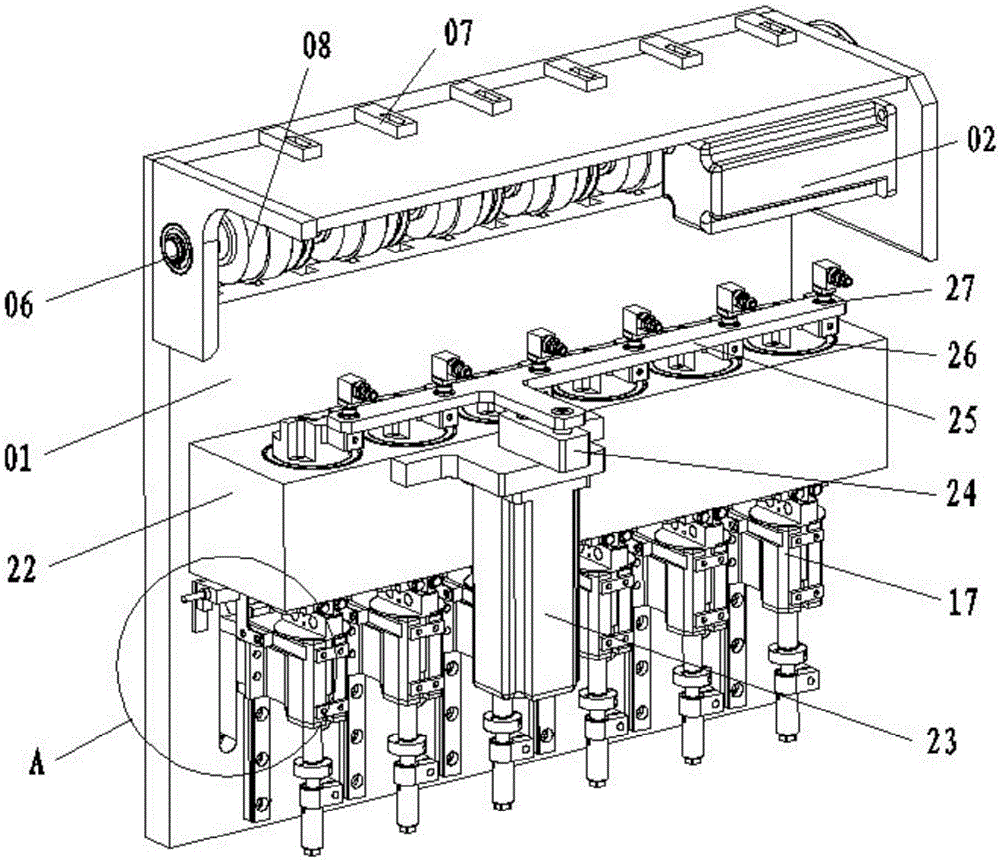

[0024] Such as figure 1 -As shown in -5, the present invention provides a multi-axis combined label handling device, comprising:

[0025] The base plate 01 has a plurality of chutes 011 aligned side by side on its lower part. The upper part of the base plate 01 is pivotally connected with a rotating shaft 06, and a plurality of electronic clutches 08 are nested side by side at equal intervals on the rotating shaft 06. The electronic clutches 08 One side is clamped to the fixed rod 16 through the buckle 081, the fixed rod 16 is fastened to the base plate 01, and the other side of the electronic clutch 08 is fixed to the upper roller 09, so One end of the suspension belt 11 is fixed on the above-mentioned upper roller 09 by a positioning block 10, and a limit block 07 is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com