Production cycle analysis method and production cycle analysis system

A technology of production cycle and analysis method, applied in manufacturing computing systems, data processing applications, instruments, etc., can solve the problems of insufficient data utilization, low reliability and versatility, and achieve the effect of avoiding waiting time and shortening production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

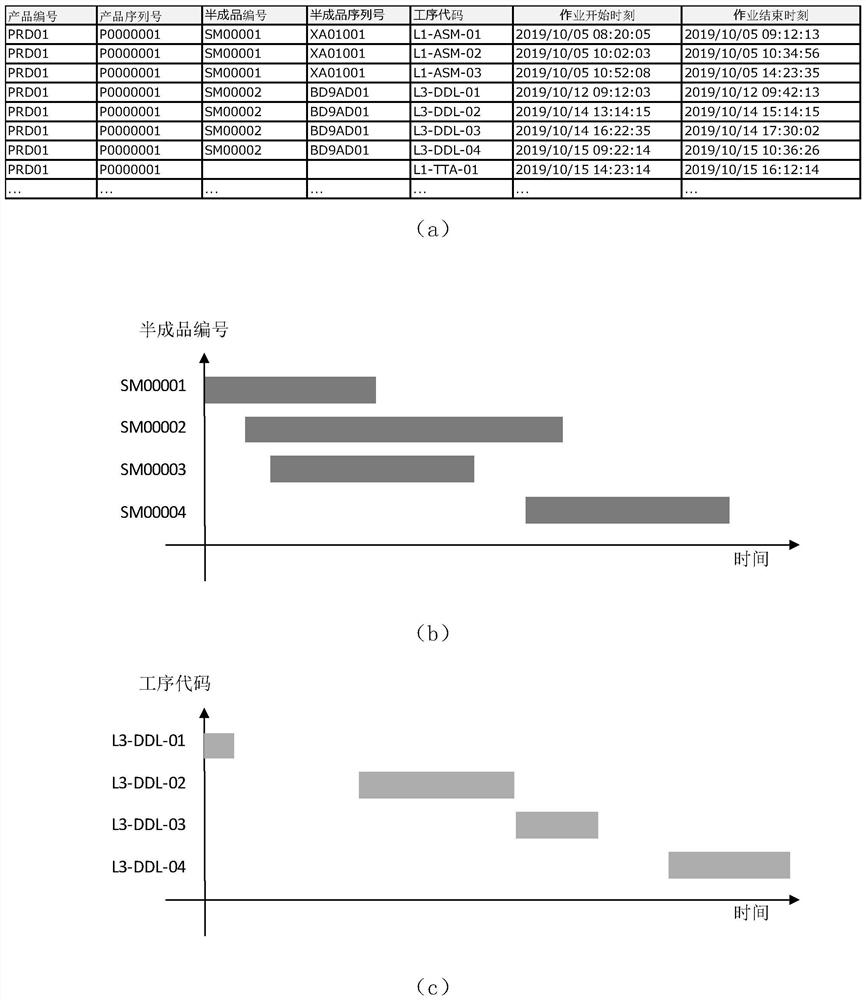

[0051] The production cycle analysis system of this embodiment analyzes the production cycle of a certain product PRD01. Each of the product PRD01 is processed by various semi-finished products through multiple processes, and each semi-finished product is processed through multiple processes.

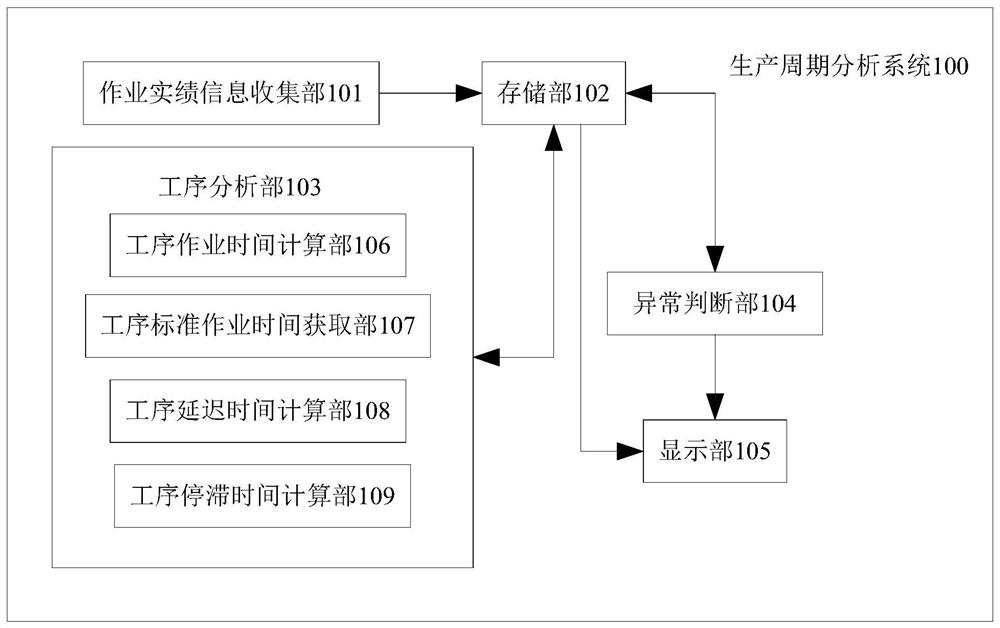

[0052] The composition of this production cycle analysis system 100 is shown in figure 1 , including an operation performance information collection unit 101 , a storage unit 102 , a process analysis unit 103 , an abnormality determination unit 104 , and a display unit 105 .

[0053] Among them, the operation performance information collection unit 101 collects operation performance information of all the processes related to each product PRD01. The job performance information such as figure 2 As shown in (a), it includes the operation start time and operation end time of each process. The data source can be collected in real time at the manufacturing site or imported from other datab...

no. 2 approach

[0065] The configuration of the production cycle analysis system 200 of this embodiment is shown in Figure 4 , in addition to the same structure as the production cycle analysis system 100 of the first embodiment, it also includes a product analysis unit 201, which is used to analyze the production cycle of each product, including a product production cycle calculation unit 202, a product standard production cycle acquisition Section 203 and product delay time calculation section 204.

[0066] Among them, the product production cycle calculation part 202 calculates the product production cycle according to the aforementioned operation performance information for each product PRD01 (that is, products with the same product number but different product serial numbers) and stores it in the storage part 102. It refers to the time difference between the operation start time of the earliest process and the operation end time of the latest process among all the processes collected by...

no. 3 approach

[0073] The configuration of the production cycle analysis system 300 of this embodiment is shown in Image 6 , in addition to the same composition as the production cycle analysis system 100 of the first embodiment, it also includes a semi-finished product analysis part 301, which is used to analyze the production cycle of each semi-finished product, including a semi-finished product production cycle calculation part 302, a semi-finished product standard production cycle acquisition part 303, a semi-finished product delay time calculation part 304, and a semi-finished product dead time calculation part 305.

[0074] Among them, the semi-finished product production cycle calculation unit 302 calculates the semi-finished product production cycle for each semi-finished product of each product PRD01 according to the aforementioned operation performance information and stores it in the storage unit 102. The semi-finished product production cycle refers to the stored in the storage u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com