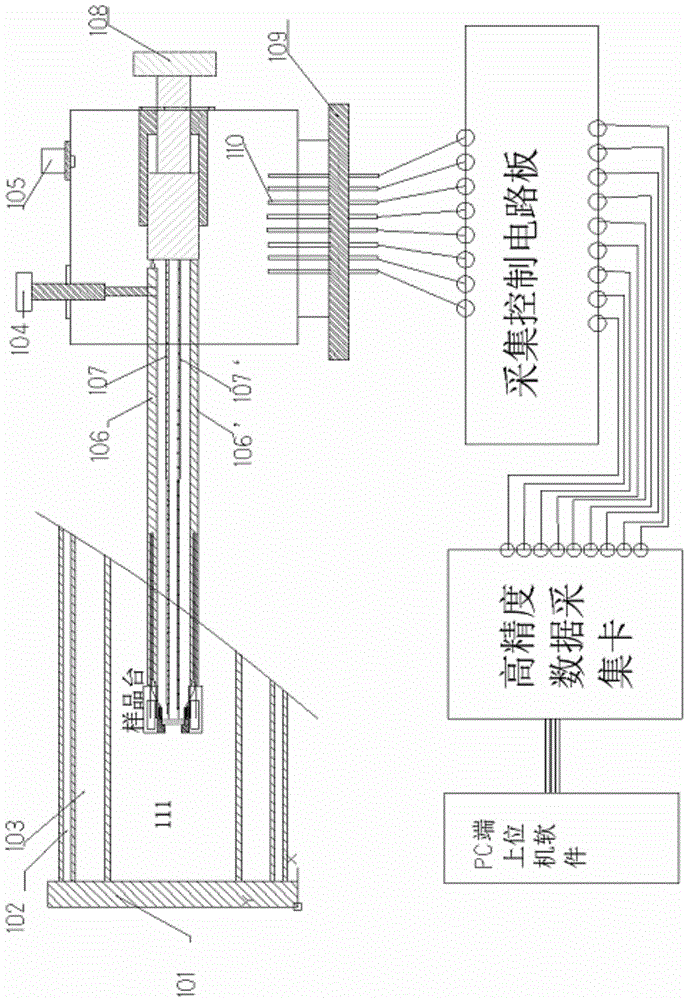

Testing method and system for automatically measuring semiconductor resistivity and Seebeck coefficient

A test method and resistivity technology, applied in the field of semiconductor material performance testing, can solve problems such as time-consuming, heating to the next temperature point, time-consuming uncertainty, etc., to avoid waiting time, save time, and avoid curve points. many effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

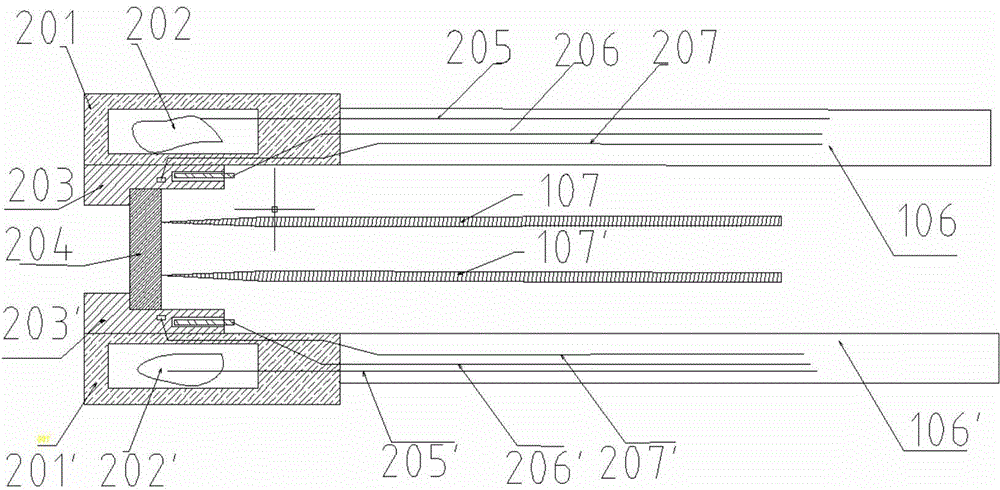

Method used

Image

Examples

Embodiment example 1

[0082] In order to verify the reliability of this system, this system conducts Seebeck and resistivity tests on the bulk sample In4Se2.5 thermoelectric material obtained by 823K high temperature melting, quenching, and 723 hot pressing for 2 hours. The test results are shown in the figure Figure 7 shown.

[0083] Table 1. Test results of bulk sample In4Se2.5 from room temperature to high temperature

[0084]

[0085]

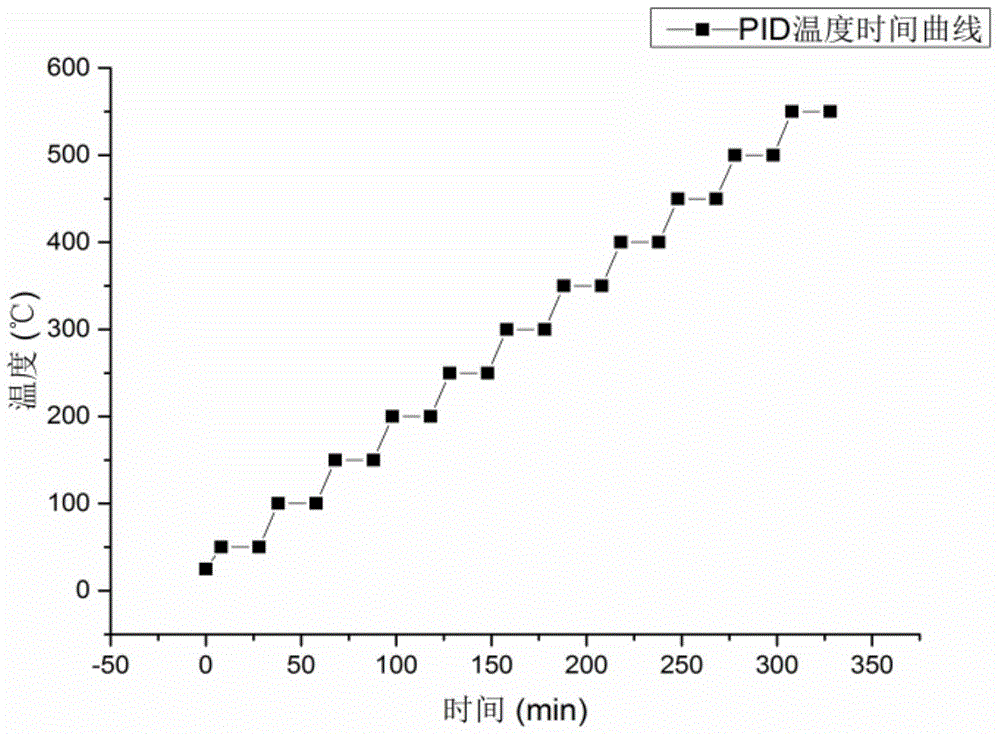

[0086] The embodiment of the present invention automatically measures the test method of semiconductor resistivity and Seebeck coefficient, such as Figure 11 shown, including the following steps:

[0087] S1. Place the sample to be tested in a vacuum environment, heat both ends of the sample to be tested, and control the temperature difference between the two ends;

[0088] S2, send PID curve at intervals, the PID curve includes three temperature points: initial temperature point, the next temperature point to be tested and the preset final test temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com