Swinging detection device for vertical shaft cage guide steel wire rope

A detection device and steel wire rope technology, applied in the field of measurement, can solve problems such as the difficulty in detecting the swing of steel wire ropes in tank roads, and achieve the effects of simple structure, guaranteed launch centering accuracy, and high measurement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

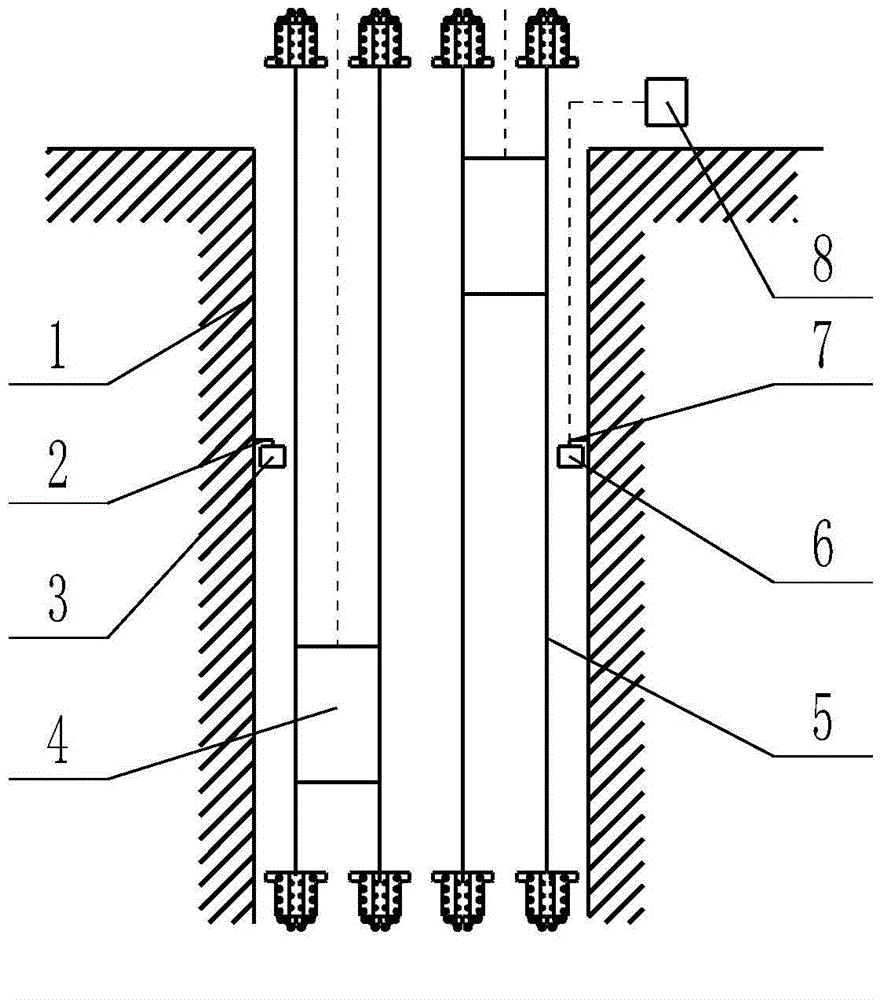

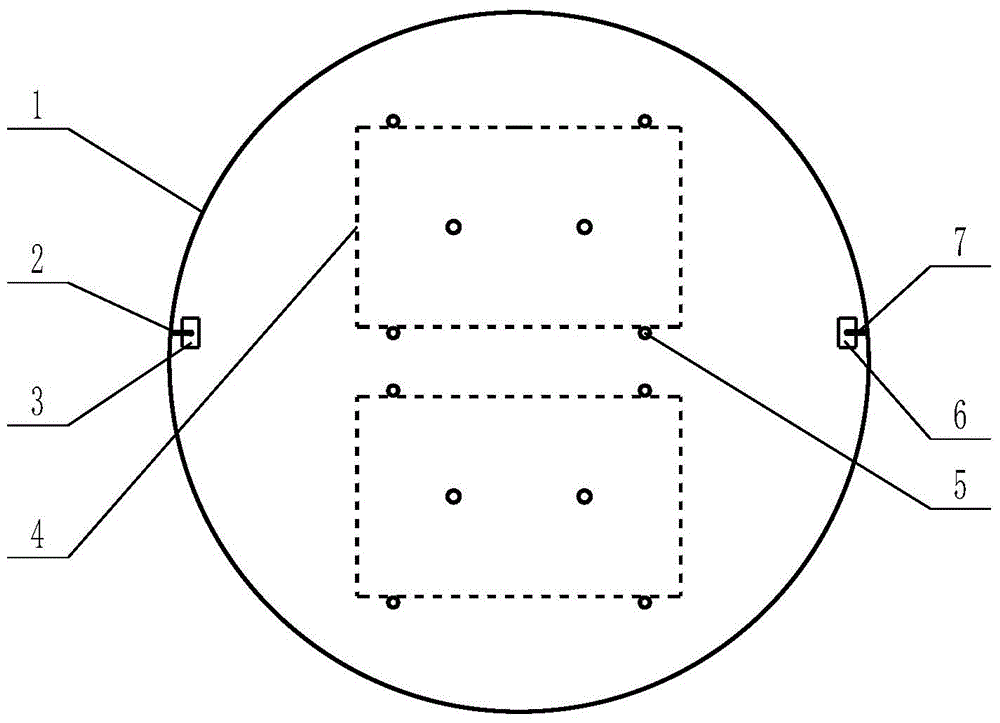

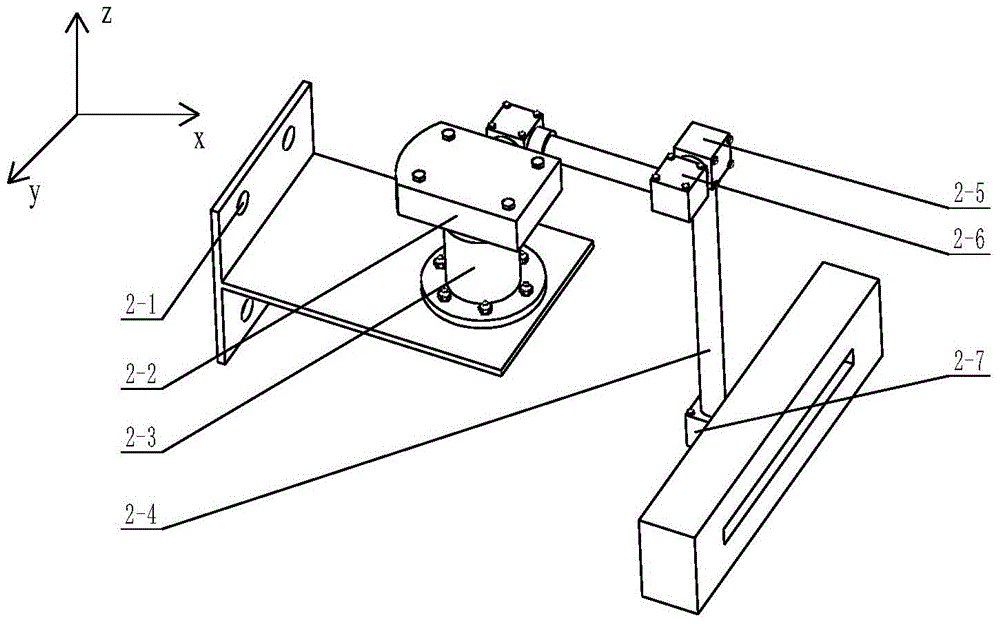

[0028] Implementation method: first, install the well wall suspension centering devices 2 and 7 on the well walls on both sides of the corresponding detection point through the bolt 2-1. It may be small, ideally within 5% of the adjustment range of the suspension centering device 2. Then, according to the signal received by the host computer 8, check the offset between the parallel light source generator 3 and the photoelectric conversion device 6, which can be suspended through the well wall. The rotation of each rotating group in the centering device 2, 7 aligns the emitting port of the parallel light source generator 3 and the receiving port of the photoelectric conversion device 6, and ensures that the measuring point of the steel wire rope of the tank is at half of the rectangular hole as far as possible. After the alignment is completed, the detection device can work normally. When working, due to the shielding effect of the tank road steel wire rope, the parallel light ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com