Disperse black dye composition, dye product and application

A technology of dye composition and disperse black, which is applied in organic dyes, dyeing methods, textiles and papermaking, etc., can solve problems such as difficult to obtain effective applications, and achieve good color synchronization and compatibility, good stability, and durability Effect of Perspiration Fastness Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

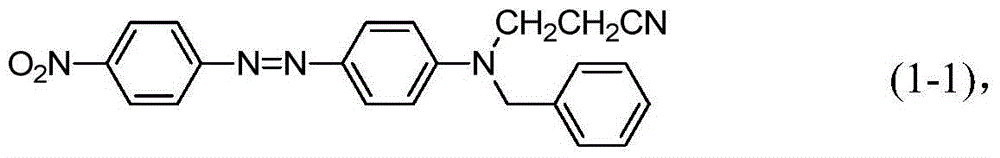

[0030] Component A shown in 20.0 grams of formula (1-1), component B shown in 16.5 grams of formula (2-1), component C shown in 8.5 grams of formula (3-1) are mixed, with pulverizer Pulverize and mix to obtain the disperse black dye composition of the present invention.

[0031] 45 grams of the above-mentioned disperse black dye composition, 55 grams of dispersant MF and 200 grams of water are ground together with a sand mill (micronized and dispersed), and then spray-dried to obtain a solid product of the disperse black dye composition. Based on the dye compound components used, wherein the mass fraction of component A shown in formula (1-1) is 44.4%, the mass fraction of component B shown in formula (2-1) is 36.7%, and the mass fraction of component B shown in formula (3-1) is The mass fraction of component C is 18.9%.

[0032] The dispersion stability of the disperse dye of the present invention at 71°C and 130°C was tested respectively according to GB / T 5540 and GB / T 5541...

Embodiment 2~3

[0035] With reference to the method of Example 1, and the consumption of each component shown in Table 1, a solid product of the disperse black dye composition of the corresponding embodiment was prepared.

Embodiment 4

[0037] With reference to the method of Example 1, and the consumption of each component shown in Table 1, grind and disperse with a sand mill, filter out the dye slurry with a filter screen when the particle diameter is less than 2 microns, and obtain the corresponding disperse black dye composition liquid products.

[0038] Table 1: Preparation Examples

[0039]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com