A spinning coiler

A winding machine and spinning technology, which is used in textiles and papermaking, conveying filamentous materials, and bundling of newly ejected filaments, etc. The effect of falling off and shortening the hanging time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

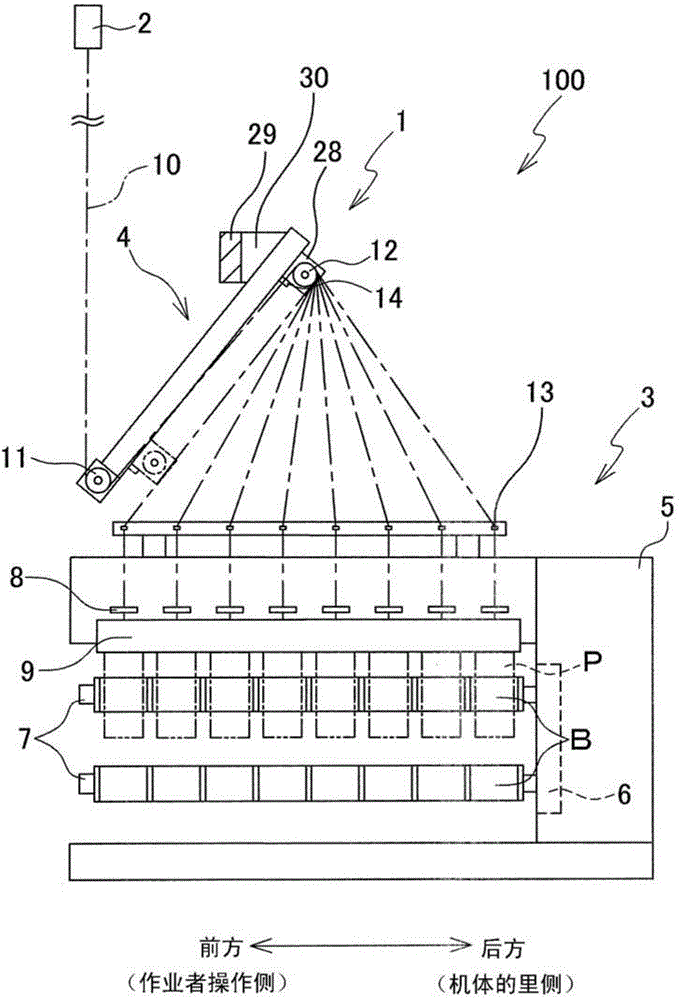

[0041] Such as figure 1 As shown, the spinning winder 100 has: a spinning drawing part 1 that draws a plurality of yarns 10 spun from a spinning machine 2; The winding part 3 of a bobbin B. In the following description, the front end side of the bobbin holder 7 described later is defined as the side on which the operator operates the spinning winder 100, that is, the front, and the opposite side is defined as the rear.

[0042] (Spinning Draw Department)

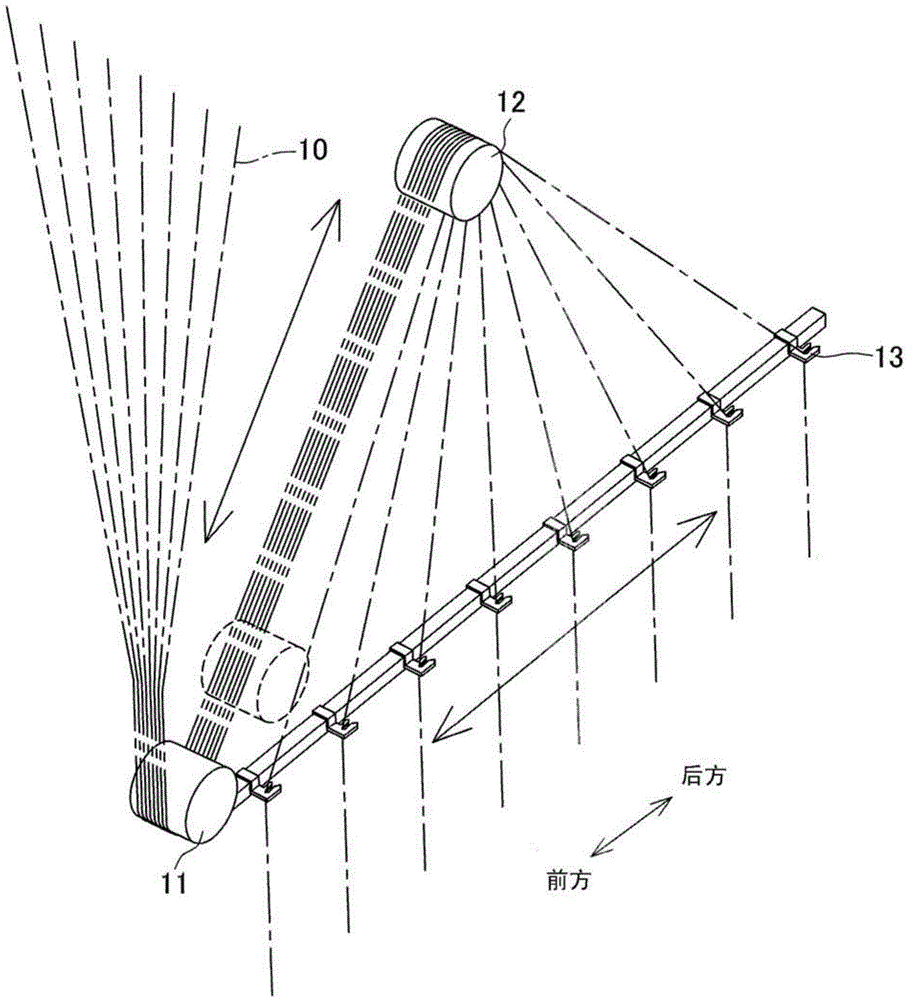

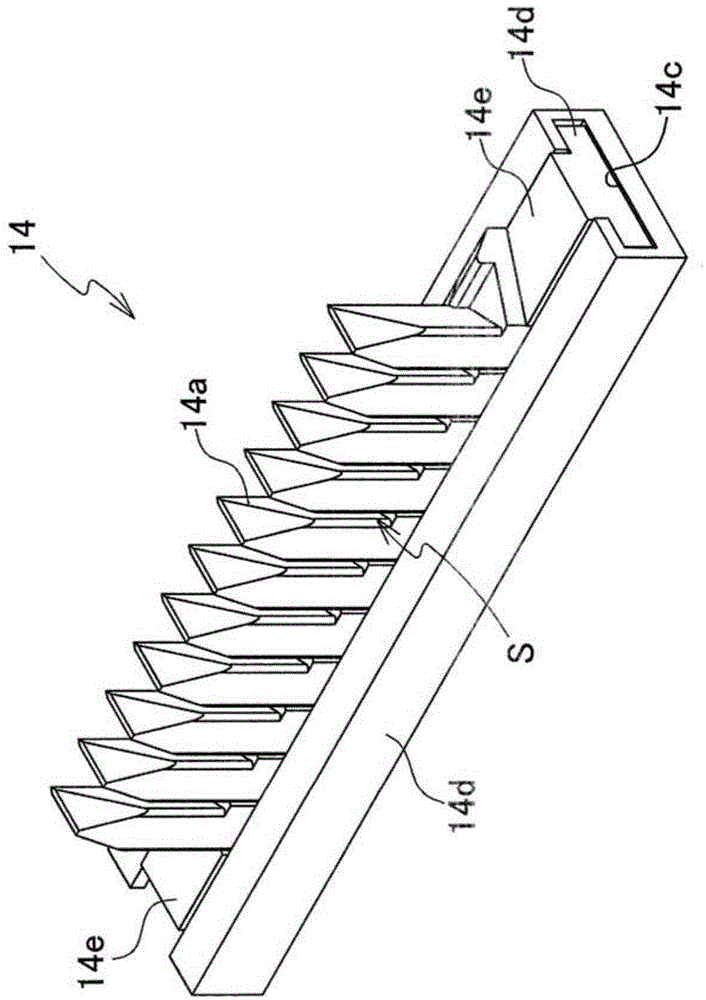

[0043] First, the spinning drawing unit 1 will be described. Such as figure 1 , figure 2 As shown, the spinning drawing unit 1 has a first godet roll 11 , a second godet roll 12 , a yarn regulating guide 14 , and a roll lifting mechanism 4 . A plurality of yarns 10 spun out from the spinning machine 2 are drawn by the first godet roll 11 and the second godet roll 12, and are drawn toward the coiling portion arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com