Kinetic energy attenuation device and general classified highway fence using same

A technology for attenuation devices and highway guardrails, applied in road safety devices, roads, roads, etc., can solve problems such as hidden safety hazards, achieve low cost and maintenance costs, wide adaptability, and achieve major innovations and technological progress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

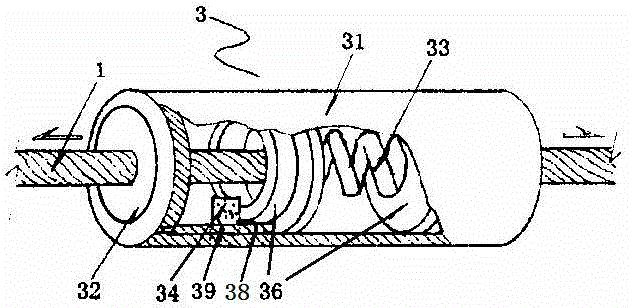

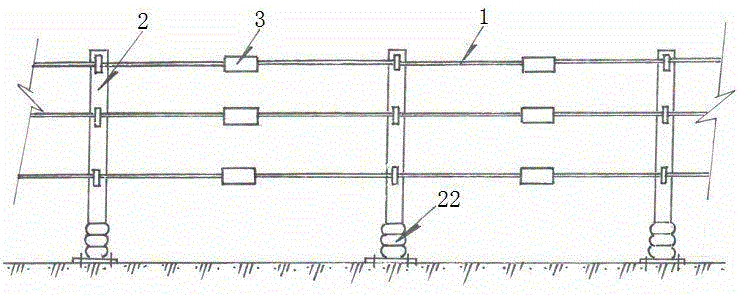

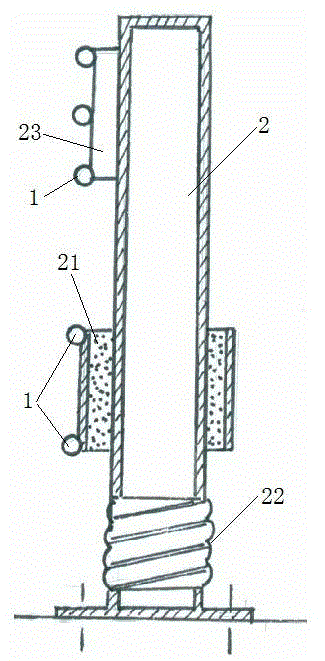

[0057] Such as Figure 1~5 As shown, a kinetic energy attenuation device 3 includes a hollow shell 31 with closed ends. The end covers 32 on both sides of the shell 31 are respectively provided with through holes for the rope 1 to pass through, and the two through holes are connected to the shell. The central axis is coaxial;

[0058] The casing 31 is cylindrical, and inner sleeves 39 are respectively embedded at both ends of the inner wall. The inner sleeve 39 fits closely with the inner wall of the casing. There is a gap between the inner sleeves 39 at both ends of the inner wall. An annular groove 35 is formed between the inner walls of the housing, and a stepped surface 38 is formed between the annular groove 35 and the inner sleeve 39, and the end covers 32 on both sides of the housing 31 are detachable;

[0059] The housing 31 is provided with a tension spring 33 capable of generating telescopic deformation and converting pressure into mechanical energy or thermal energy, th...

Embodiment 2

[0068] Such as Image 6 , Figure 7 As shown, the embodiment 1 is repeated, the difference is: the damaged body is a hollow destructible body 37 made of rigid material, and the hollow destructible body 37 is provided with a through hole for the rope 1 to pass through. The hollow damageable body 37 is placed in the cavity between the cylindrical pressing block 36 and the end caps 32 on both sides of the shell.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com