Seat rail module for a vehicle seat for vehicle seat deceleration in the event of a crash

A technology for seat guide rails and vehicle seats, which is applied in the direction of vehicle seats, special positions of vehicles, movable seats, etc., can solve the problems of reduced effectiveness of the occupant restraint system, and achieve the effect of compact geometry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

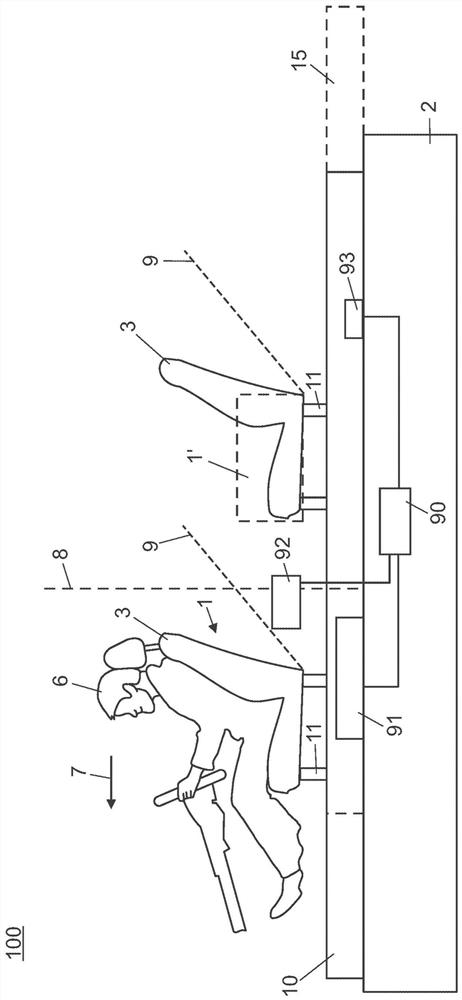

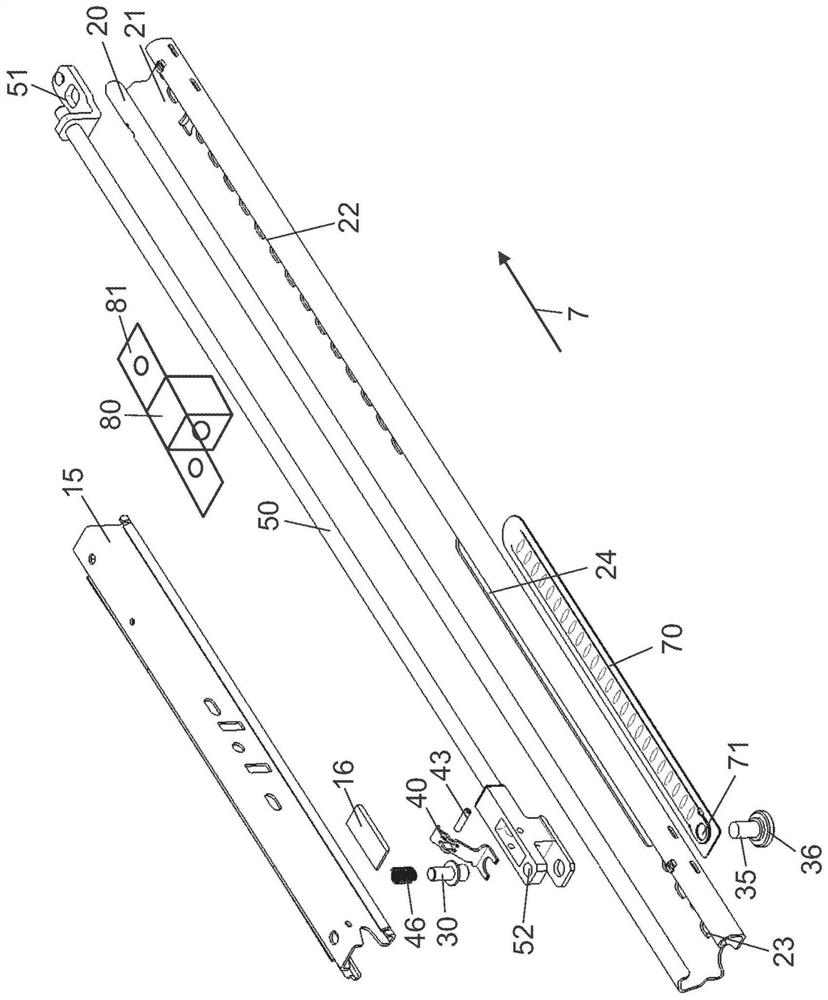

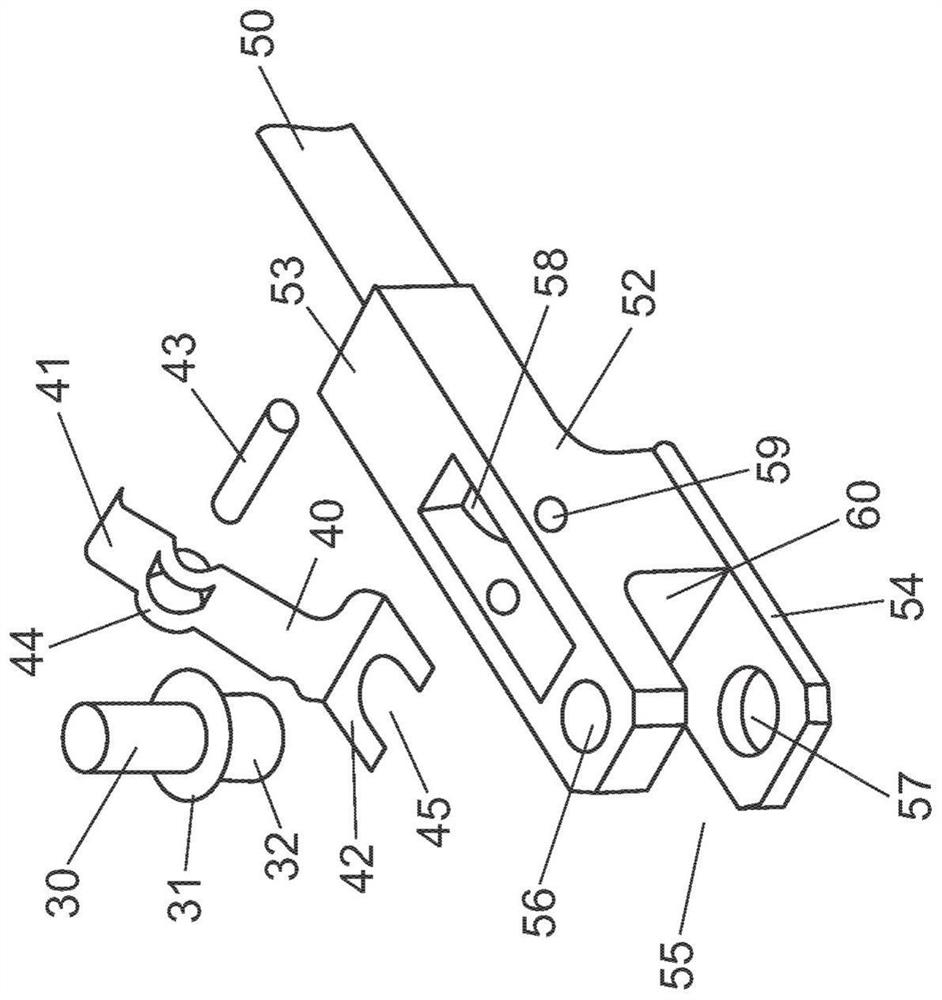

[0047] figure 1 The general structure of the seat rail module 100 according to the invention and its arrangement in the passenger compartment of a motor vehicle is shown in a schematic side view. The floor 2 of the vehicle is only schematically shown here and is suitably shaped according to the specifications of the vehicle manufacturer. exist figure 1 In and in the other figures, the direction of the main direction of travel is indicated by an arrow and reference numeral 7 . according to figure 1 , the seat rail module 100 comprises two rails 10 for longitudinal adjustment, which extend parallel to each other and are fastened to the floor 2 of the vehicle, each of the rails 10 for longitudinal adjustment Comprising a lower rail 20 (hereinafter also referred to as a lower rail) and an upper rail 15 (hereinafter also referred to as an upper rail), the lower rail 20 is connected to the floor 2 of the vehicle, and the upper rail 15 is supported such that the upper The guide r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com