Adjusting device for an adjusting piston of a variable clearance space of a reciprocating compressor

A technology for adjusting pistons and adjusting devices, which is applied to liquid variable displacement machines, mechanical equipment, machines/engines, etc., and can solve problems such as high basic loads and unsuitable high pulse loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

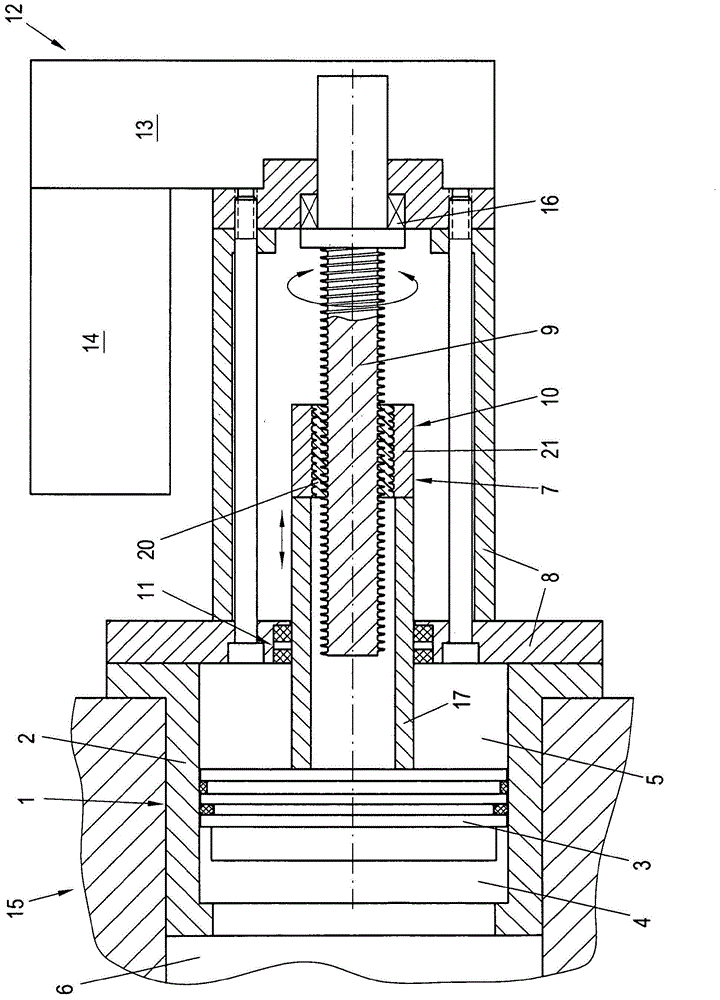

[0019] according to figure 1 The variable clearance space 1 comprises a clearance space housing 2 in which an adjusting piston 3 is axially guided and arranged axially displaceable by means of an adjusting device 7 . The interstitial space housing 2 is arranged in a manner known per se on the cylinder 6 of the piston compressor 15 . The chamber 4 facing the cylinder 6 and delimited by the adjusting piston 3 in the interstitial space housing 2 is connected to the cylinder chamber of the piston compressor 15 and forms an additional clearance volume of the cylinder 6 .

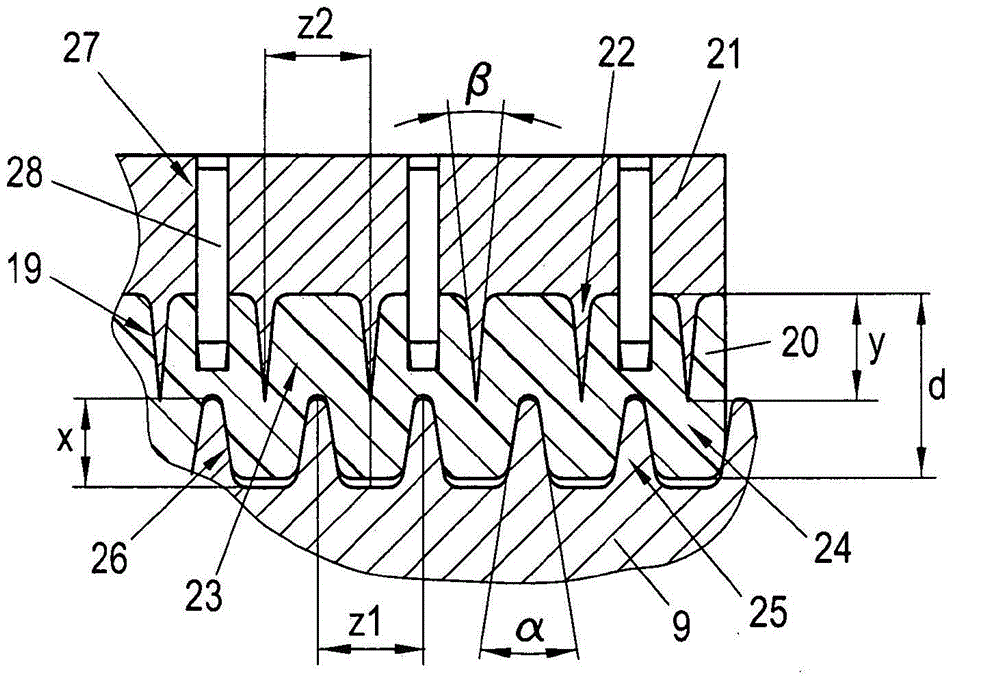

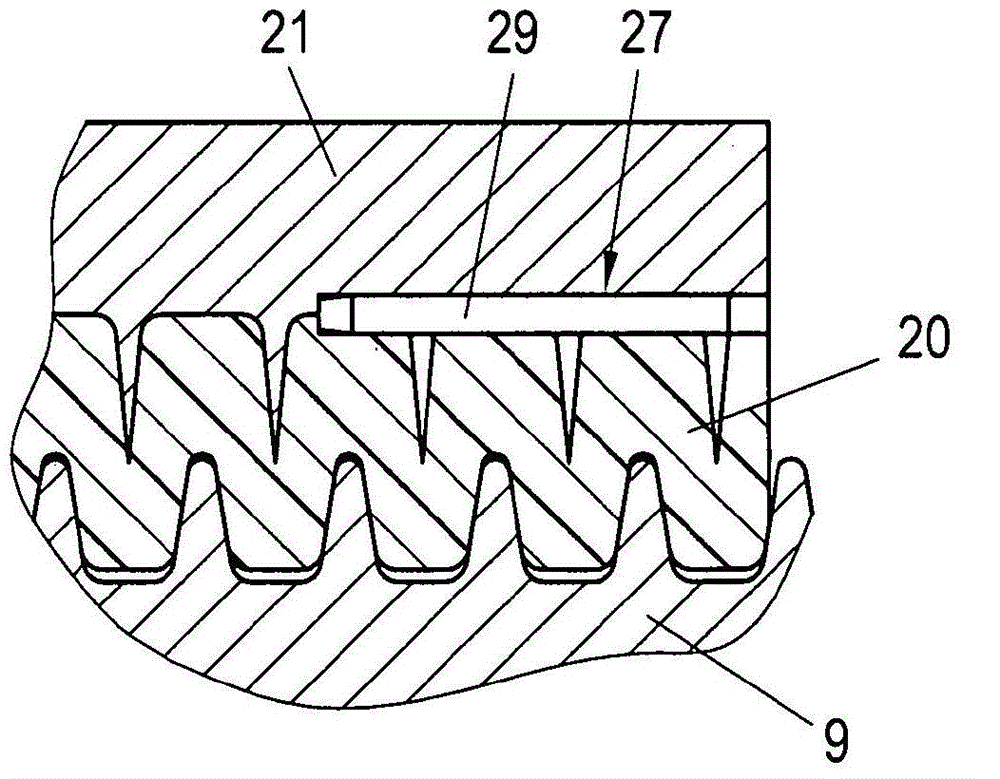

[0020] Fastened to the interstitial space housing 2 is an adjustment housing 8 in which the adjustment device 7 is arranged. Obviously, the interstitial space 1 and the adjustment device 7 can also be arranged in a common housing. The adjusting device 7 comprises a spindle drive with a threaded spindle 9 which has an external thread which is screwed into an internal thread of a spindle nut 10 . The spindle nu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com