Novel anti-loose bolt

A new type of technology for anti-loosening bolts, applied in the direction of bolts, screws, nuts, etc., can solve problems such as loosening, inconvenience for users, and increased maintenance rate of bolt equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

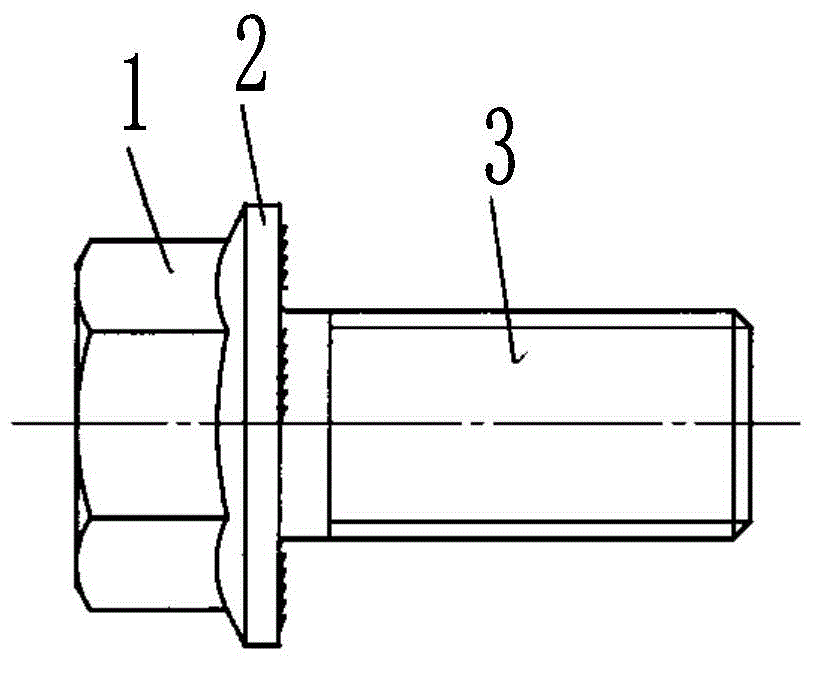

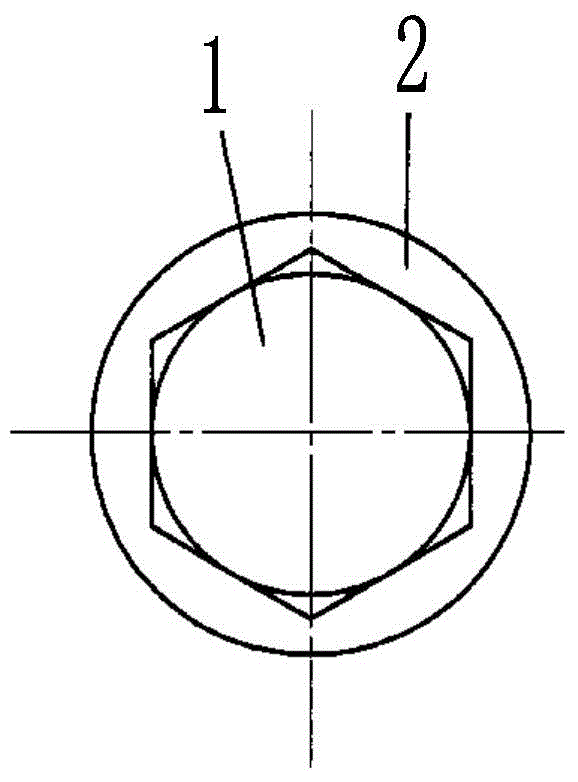

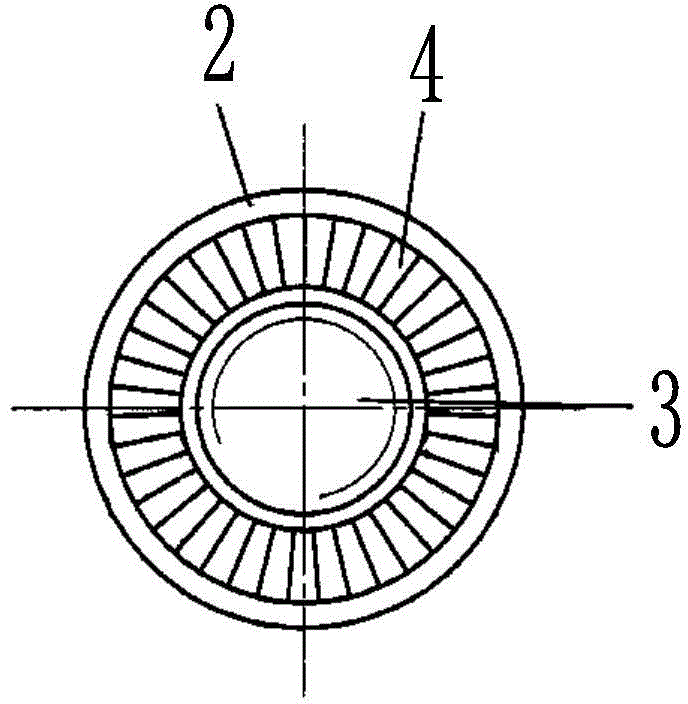

[0011] like figure 1 , 2 , 3, the present invention is provided with a flange 2 on one side of the hexagonal screw 1, and a stud 3 is provided on one side of the flange 2, and the hexagonal screw 1, the flange 2 and the stud 3 are on the same central line at the center, and the diameter of the flange 2 is greater than the diameter of the hexagon screw head 1. A circle of anti-loosening teeth 4 are evenly distributed on the outer periphery of one side of the flange 2 . Through the above settings, the present invention is used for the fastening of components. The anti-loosening teeth 4 on the flange 2 are in contact with the surface of the fastened component. When the equipment is running, it will not be shaken by the equipment and other reasons. Loose, reducing the failure rate of equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com