Planetary differential structure of electronically-controlled transfer case

A transfer case and planetary technology, applied in the field of auto parts, can solve the problems of high resistance and difficulty in shifting, and achieve the effect of simple shifting, good market application value, and low resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

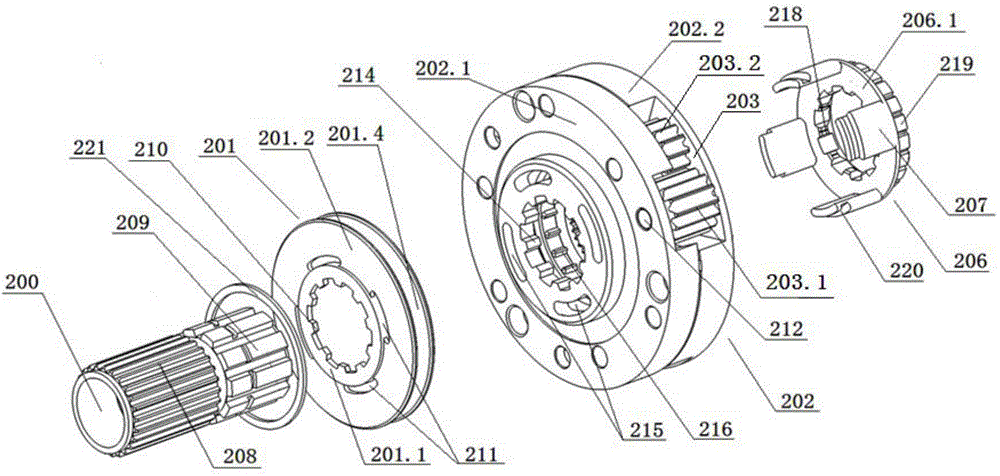

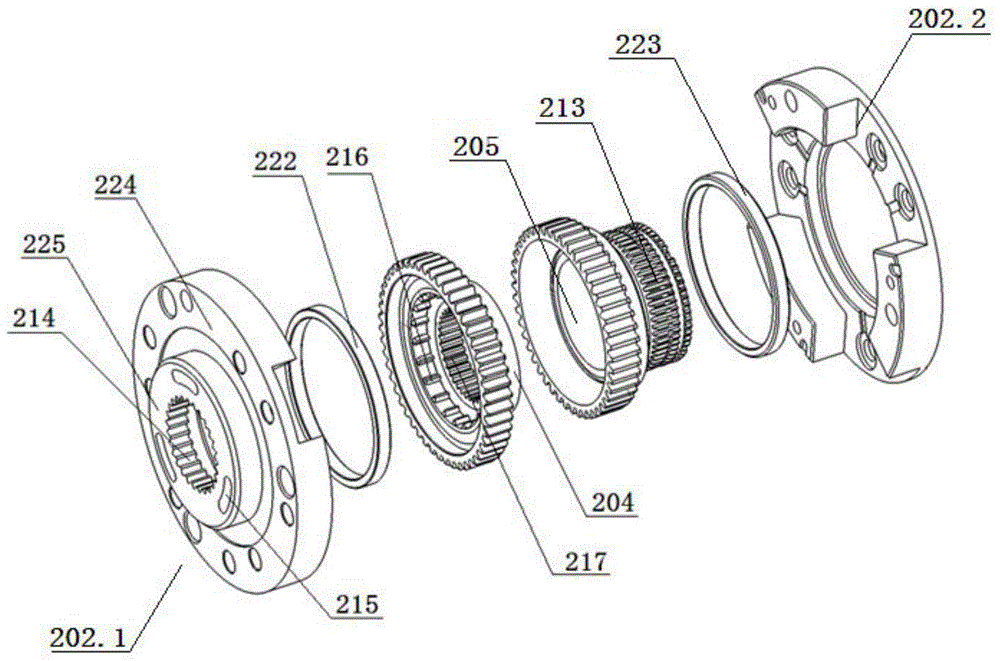

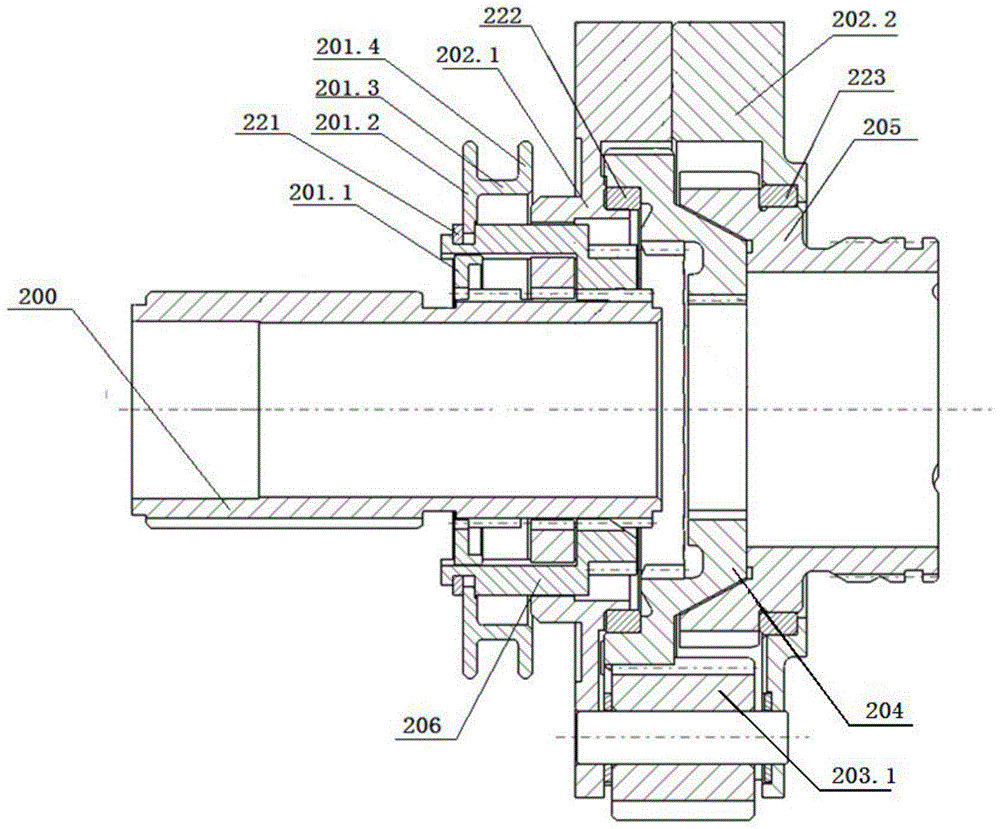

[0020] Such as figure 1 - The planetary differential structure of the electronically controlled transfer case shown in 3, including the drive shaft sleeve 200 sleeved on the drive shaft of the rear axle, and the differential lock shift fork sleeve 201 sleeved on the drive shaft sleeve 200 and the differential case 202; the spline connection between the drive shaft sleeve 200 and the differential lock shift fork sleeve 201; The sun gear 204 and the rear sun gear 205, the rear sun gear 205 is sheathed in the rear portion of the front sun gear 204, the rear portion of the rear sun gear 205 is provided with transmission gear teeth 213 meshed with the sprocket, the rear portion of the front sun gear 204 The circle is provided with an inner spline that cooperates with the outer spline of the rear axle drive shaft, and the planetary differential struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com