Lens, lens assembly and manufacture method of lens

A manufacturing method and lens technology, applied in the directions of lens, installation, optics, etc., can solve the problems of difficulty in gasket manufacturing, limitation of gasket arrangement, inability to arrange gaskets, etc., and achieve the effect of improving efficiency, reducing quantity, and improving the quality of imaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

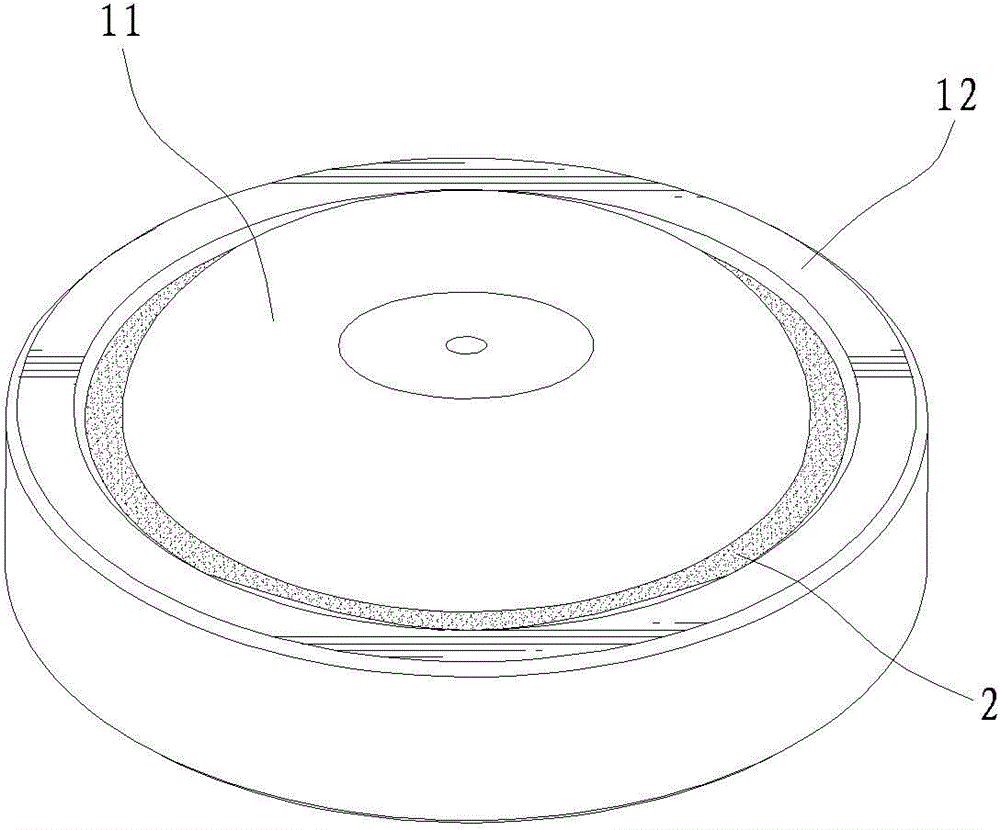

[0068] refer to Figure 2A and Figure 2B Shown, this embodiment is a kind of lens, comprises:

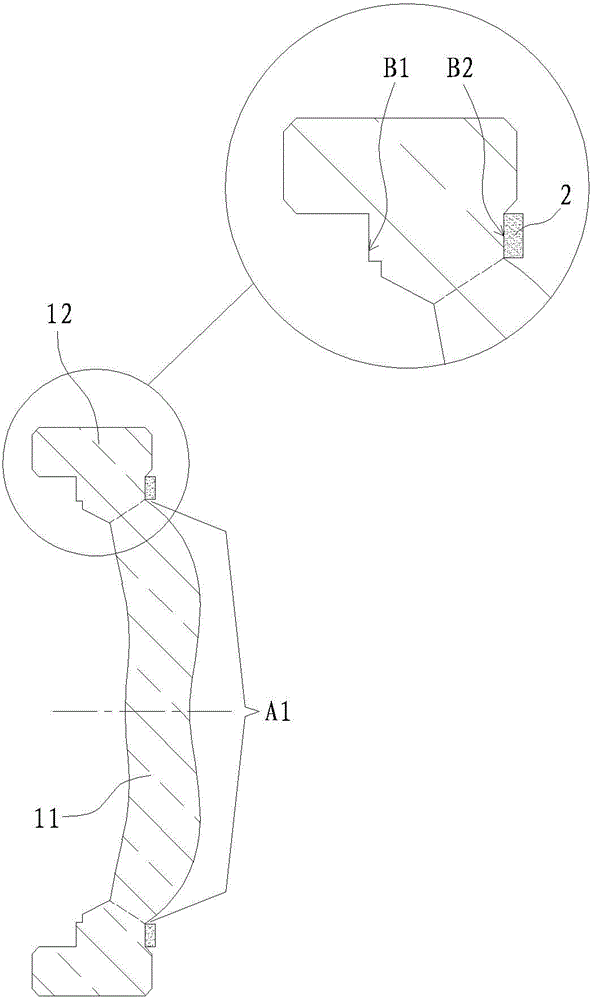

[0069] A lens body 1 includes an optically effective portion 11 and an extension portion 12. The optically effective portion 11 refers to the area A1 for the ideal imaging light to pass through. The extension portion 12 is annular and defined by the outer circumference of the optically effective diameter The edge extends to the outer peripheral edge of the lens body, and the extension portion 12 surrounds the optical effective portion 11, and the ideal imaging light does not pass through the extension portion 12, the lens body 1 has a The annular surface B1 outside A1 and the annular surface B2 facing the image side and located outside the optically effective part A1, that is, the extension part 12 corresponds to the side of the two light-transmitting surfaces (object side and image side) of the lens body Each has an annular surface B1, B2. The annular surface B2 in this embodim...

Embodiment 2

[0072] refer to image 3 As shown, this embodiment is basically the same as Embodiment 1, except that the light blocking layer 2 is formed on the annular surface B1 of the extension portion 12 in addition to being formed on the annular surface B2 of the extension portion 12 . Similarly, the material selection of the light-blocking layer 2 and the manner in which the light-blocking layer 2 is formed on the annular surfaces B1 and B2 of the extension portion 12 can refer to the description of the first embodiment.

Embodiment 3

[0074] refer to Figure 4 As shown, this embodiment is basically the same as Embodiment 1, except that: the surface of the lens body 1 includes an anti-reflection layer (anti-reflection layer) 3 covering the optical effective part 11 and the extension part 12, covering the The lens body 1 of the anti-reflection layer 3 can improve the optical transmittance. In this embodiment, after the anti-reflection layer 3 is pre-covered (usually by coating) on the optically effective part 11 and the extension part 12 of the lens body 1, the light blocking layer 2 is formed on the annular surface B2 of the extension part 12. covered by an anti-reflection layer 3 outside. This method is more realized by processing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com