Polymorphic job shop layout optimization method based on CA-PSO (Cellular Automata-Particle Swarm Optimization) hybrid optimization algorithm

A layout optimization, job shop technology, applied in computing, instrumentation, data processing applications, etc., can solve problems such as insufficient optimization ability, slow convergence, and large amount of calculation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] The content of the present invention will be specifically described below in conjunction with the accompanying drawings and embodiments.

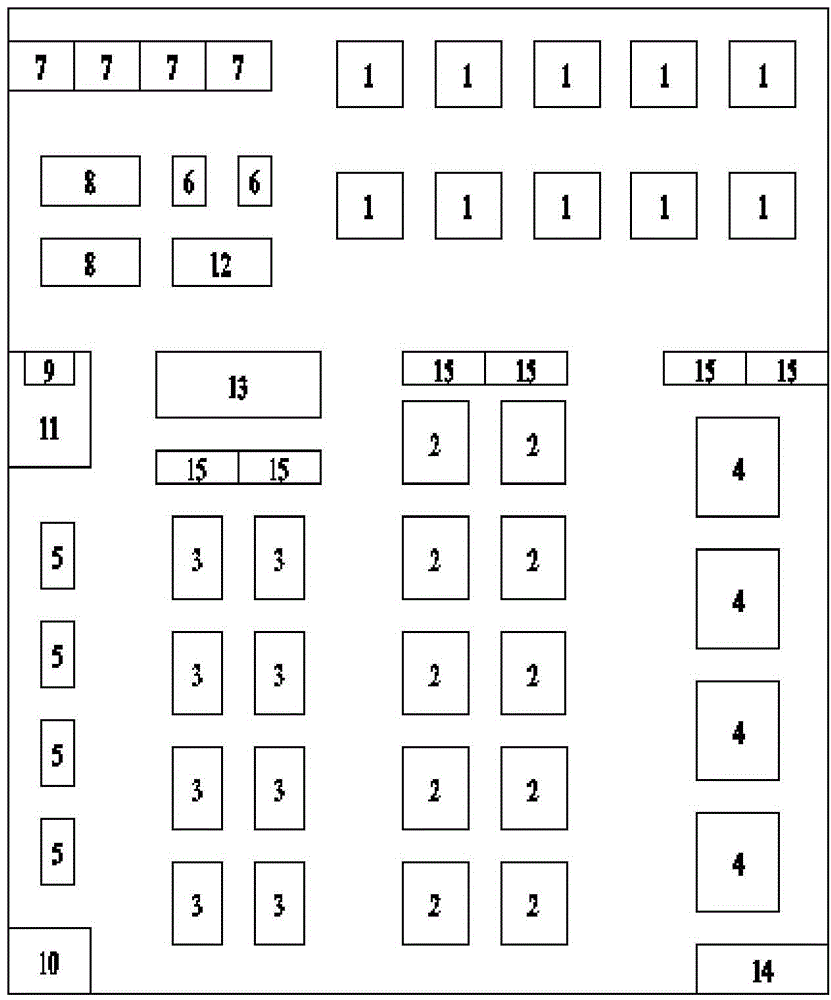

[0078] The area of an automobile tailpipe production workshop is 35m×30m, and the resources to be arranged are shown in Table 1, such as wired cutting machine and punching machine; the logistics flow between each machine is shown in Table 2. The minimum distance between machines m i =0.9m; the minimum spacing a of auxiliary equipment i =0.8m; The material handling between each equipment adopts trolley, and the unit price of handling is 1.5×10 -4 Yuan / m×piece.

[0079] Table 1 Size and quantity of equipment

[0080]

[0081] Table 2 Logistics volume between equipment (unit: piece)

[0082]

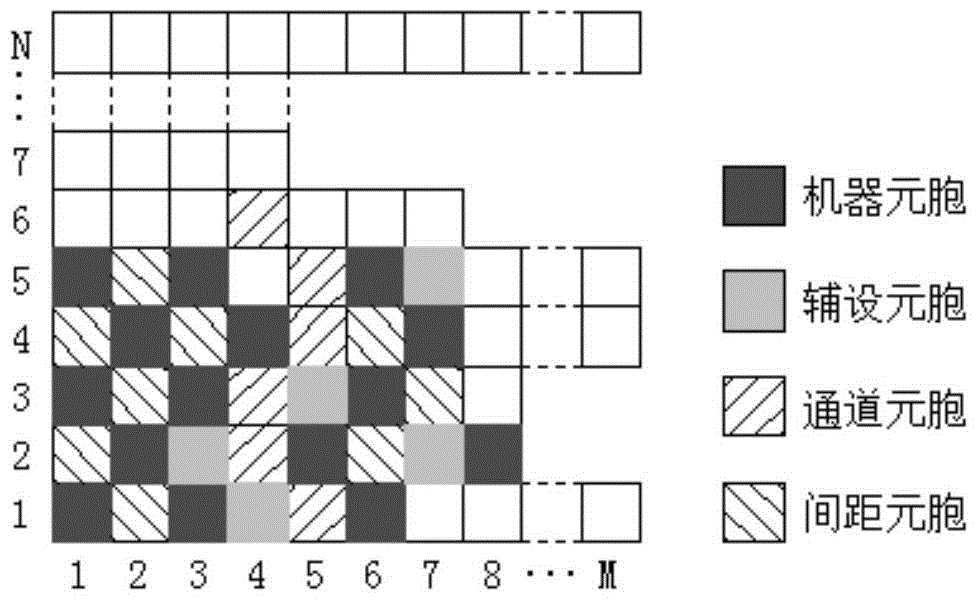

[0083] 1) There are 45 building machine cells, 11 auxiliary building cells, 30 channel cells and 56 spacing cells.

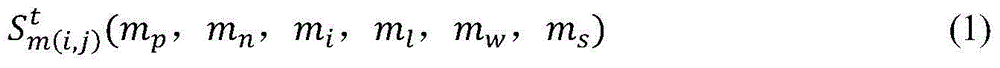

[0084] The state attribute of the machine cell at time t is expressed as:

[0085] S ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap