Flag-shaped duckbilled terminal

A terminal and duckbill technology, applied in the field of flag-shaped duckbill terminals, can solve the problems of inconvenient insertion, easy damage, insufficient locking force of the terminal, and achieve the effect of improving the service life and reducing the bearing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

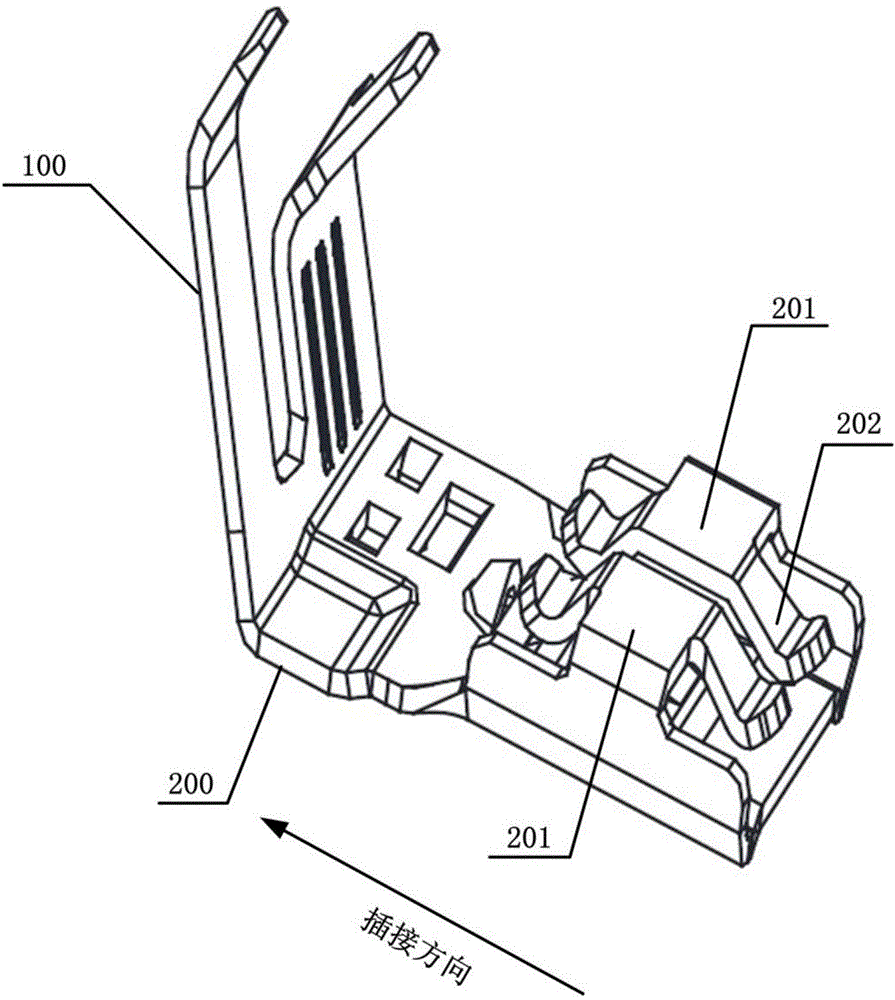

[0028] The present invention provides a flag-shaped duckbill terminal, the three-dimensional view of the flag-shaped duckbill terminal is as follows figure 1 shown. figure 1 Among them, the flag-shaped duckbill terminal includes a cable connection part 100 and a wiring female terminal 200, the insertion direction of the cable connecting part 100 and the wiring female terminal 200 is vertical, and the wiring female terminal 200 includes a slot with two slots The upper part of the vertical side wall of the side is connected with two elastic planes 201 respectively extending to the middle and used to cover the male terminal. A gap is formed between the two elastic planes 201, and each elastic plane 201 has a downward direction on both sides. The extended elastic arm 202 extends close to the bottom of the slot. In this way, there are four extended elastic walls. When the socket slot is inserted into the male terminal, the end of the extended elastic arm 202 will generate downward...

Embodiment 2

[0032] In this embodiment, a flag-shaped duckbill terminal is provided. On the basis of Embodiment 1 above, the end of the extended elastic arm 202 is bent upwards, and the end of the extended elastic arm facing the direction of the socket is bent upwards. , so that the elastic wall has a better guiding effect, and it is more convenient for the male terminal to be inserted. The end of the extended elastic arm 202 on the other side is bent upward, which makes it easier to pull out the male terminal and reduces the resistance of the barb structure.

[0033]The length of the extended elastic arm 202 toward the direction of the slot socket is greater than the length of the extended elastic arm 202 toward the other side. The function of locking and fixing, the length of the extended elastic arm towards the slot socket is relatively large, making it easier and more convenient to insert the male terminal from the slot socket, and the length of the extended elastic arm on the other si...

Embodiment 3

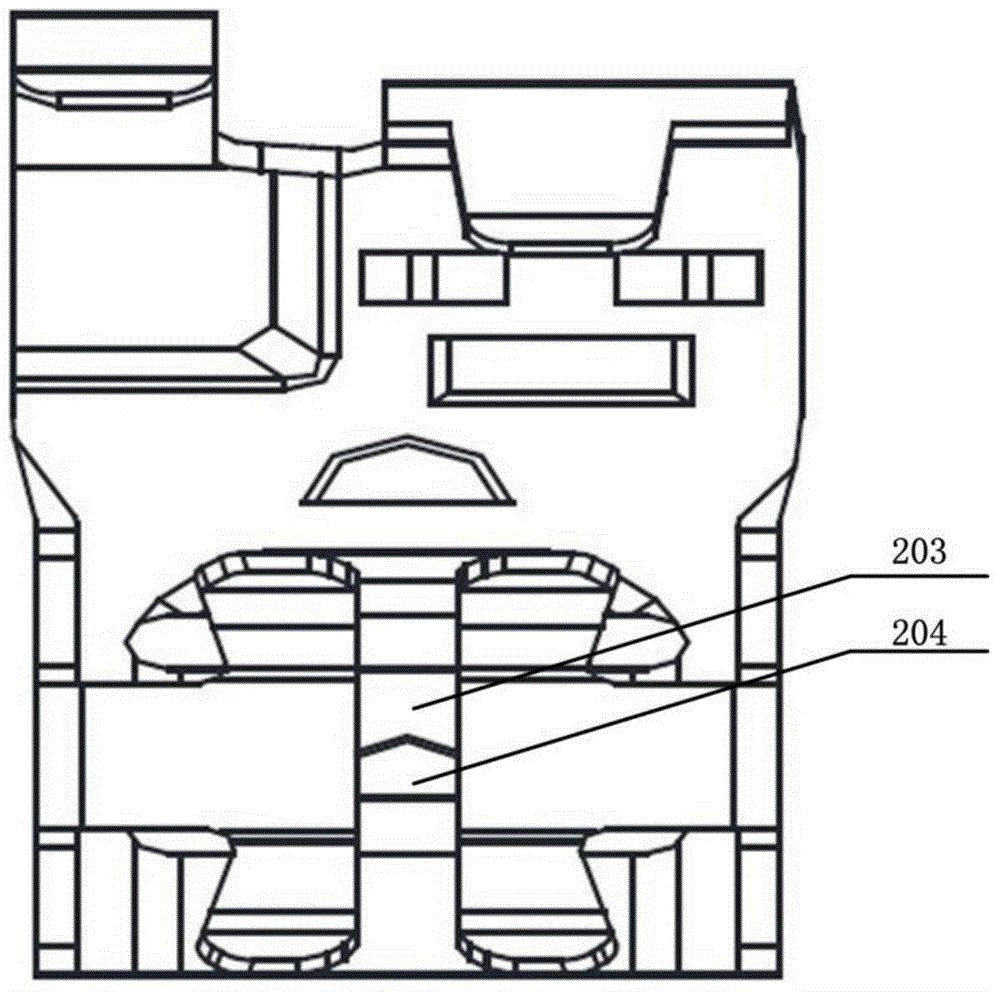

[0038] In this embodiment, a flag-shaped duckbill terminal is provided. On the basis of the above-mentioned embodiment 2, an elastic piece 203 parallel to the elastic plane 201 is provided at the bottom of the slot, such as figure 2 The front view of the flag duckbill terminal is shown. The length of the elastic sheet 203 along the insertion direction is equal to the length of the elastic plane 201 along the insertion direction, and the elastic sheet 203 is provided with locking protrusions 204 . The locking bumps 204 can be correspondingly snapped into the holes of the male wiring terminals, so that the male wiring terminals are locked and will not fall off easily, and the upper surface of the male wiring terminals forms a line contact with a plurality of extended elastic arms 202, which further ensures The locking force of the flag duckbill terminal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com